Method for extraction of paclitaxel from taxus chinensis

A technology of paclitaxel and yew, applied in the direction of organic chemistry, can solve the problems of high cost, high equipment requirements, complicated paclitaxel extraction process, etc., and achieve the effect of low production cost, small irreversible adsorption and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

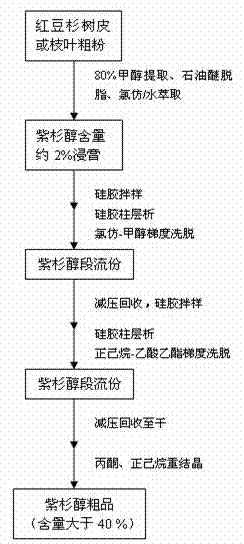

[0046] The optimization of embodiment 1 paclitaxel extraction method

[0047] Paclitaxel is a tricyclic diterpene taxane, soluble in ethyl acetate, chloroform, ethanol, methanol and acetone, insoluble in water. The content of paclitaxel in yew plants is very low, and the content in the dry bark of yew is about 0.01-0.03%. At the same time, paclitaxel is easily degraded or isomerized into other taxane compounds under the influence of temperature, organic solvent, acid, alkali and other conditions. The production process adopts organic solvent extraction, and then removes polar impurities by extraction.

[0048] Currently, the organic solvents for leaching paclitaxel include methanol, ethanol, ethyl acetate-acetone, and the like. The physical and chemical properties of commonly used organic solvents are listed in Table 1. The ethyl acetate-acetone extraction effect is better than the price, and the extraction cost is relatively high. Ethanol has low toxicity and is commonly ...

Embodiment 2

[0082] Embodiment 2 paclitaxel crude product preparation

[0083] (1) Take 300kg of Northeastern yew bark (or other yew bark or branches and leaves), crush it, add 80% methanol for warm extraction for 3 times (40℃~50℃, the quality of methanol solution is yew bark powder 5, 4, and 4 times the mass), each time for 3 hours, combine the methanol extracts, recover under reduced pressure until there is no alcohol smell (about 500L), add chloroform for extraction 4 times (the volumes of chloroform added in the 4 times are respectively 300L, 250L, 250L and 250L), the chloroform extraction layer was combined, and recovered under reduced pressure to a thick paste (7.5kg).

[0084] (2) Extract the extract with chloroform, degrease with petroleum ether twice (100L of petroleum ether is added each time, dissolve, filter at room temperature), evaporate the petroleum ether residue, and obtain the degreased extract (2.5kg).

[0085] (3) Take 2.5 kg of degreased extract, dissolve it in chloro...

Embodiment 3

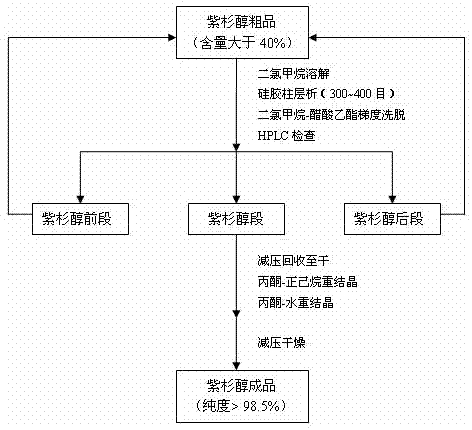

[0089] Embodiment 3 paclitaxel pure product preparation

[0090] Take 21kg of 300-400 mesh thin-layer silica gel, 100g of cuprous oxide, 100g of ammonium chloride, and 100g of hydroxylamine hydrochloride, mix them, dissolve them into a paste with a mixture of 16L of methanol and 6L of purified water, stir for 2 hours, and reduce Dry it under pressure for 12 hours, dissolve it into a paste with 55L of dichloromethane, and pack it into a column.

[0091] Weigh 200 g of paclitaxel crude product (content > 40%) prepared in Example 2, add 2 L of dichloromethane to dissolve, filter, and the filtrate is loaded on a treated industrially prepared silica gel chromatographic column (silica gel for thin layer chromatography, 300 ~ 400 mesh, 8kg, 25×100cm), add dichloromethane-ethyl acetate gradient elution (dichloromethane, 10L; dichloromethane-ethyl acetate (4:1), 12.5L; dichloromethane-ethyl acetate Ester (3:1), 12.5L; dichloromethane-ethyl acetate (2:1), 25L), dichloromethane-ethyl ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com