Intelligent wheel hub bearing unit

A kind of hub bearing, intelligent technology, applied in the direction of bearing components, hubs, shafts and bearings, etc., can solve problems such as failure to detect in time, and achieve the effect of avoiding major traffic accidents, reducing weight and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

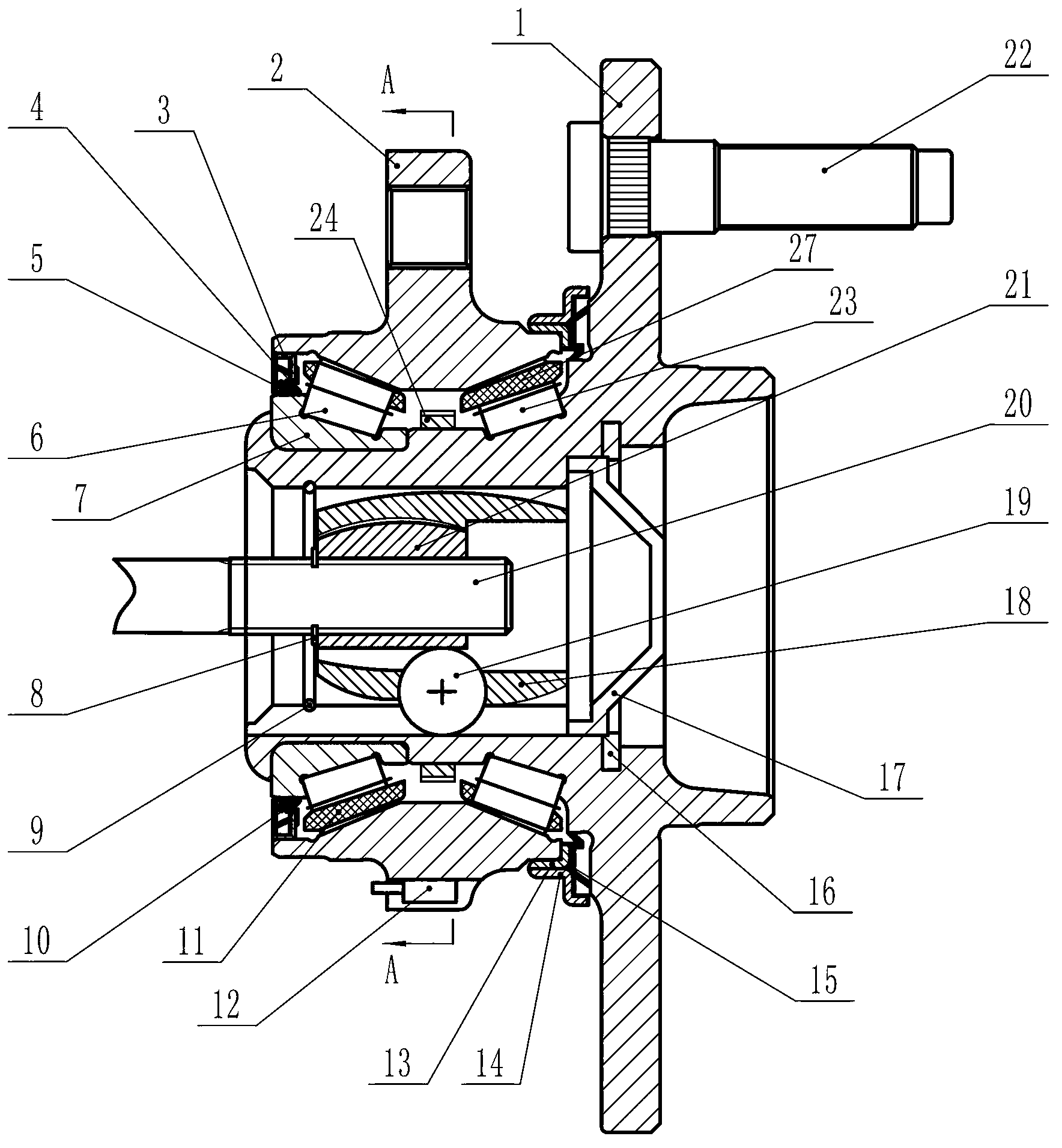

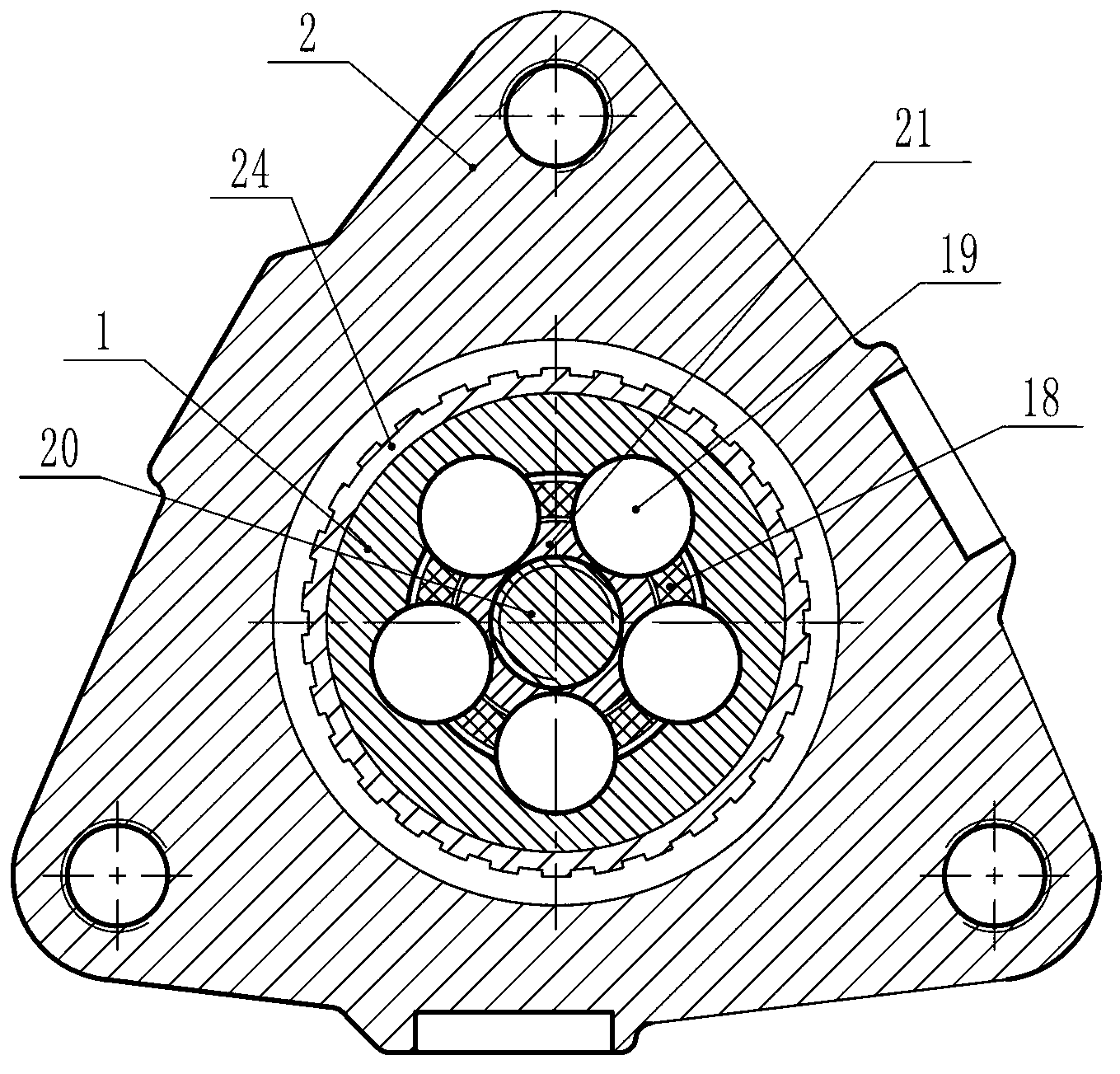

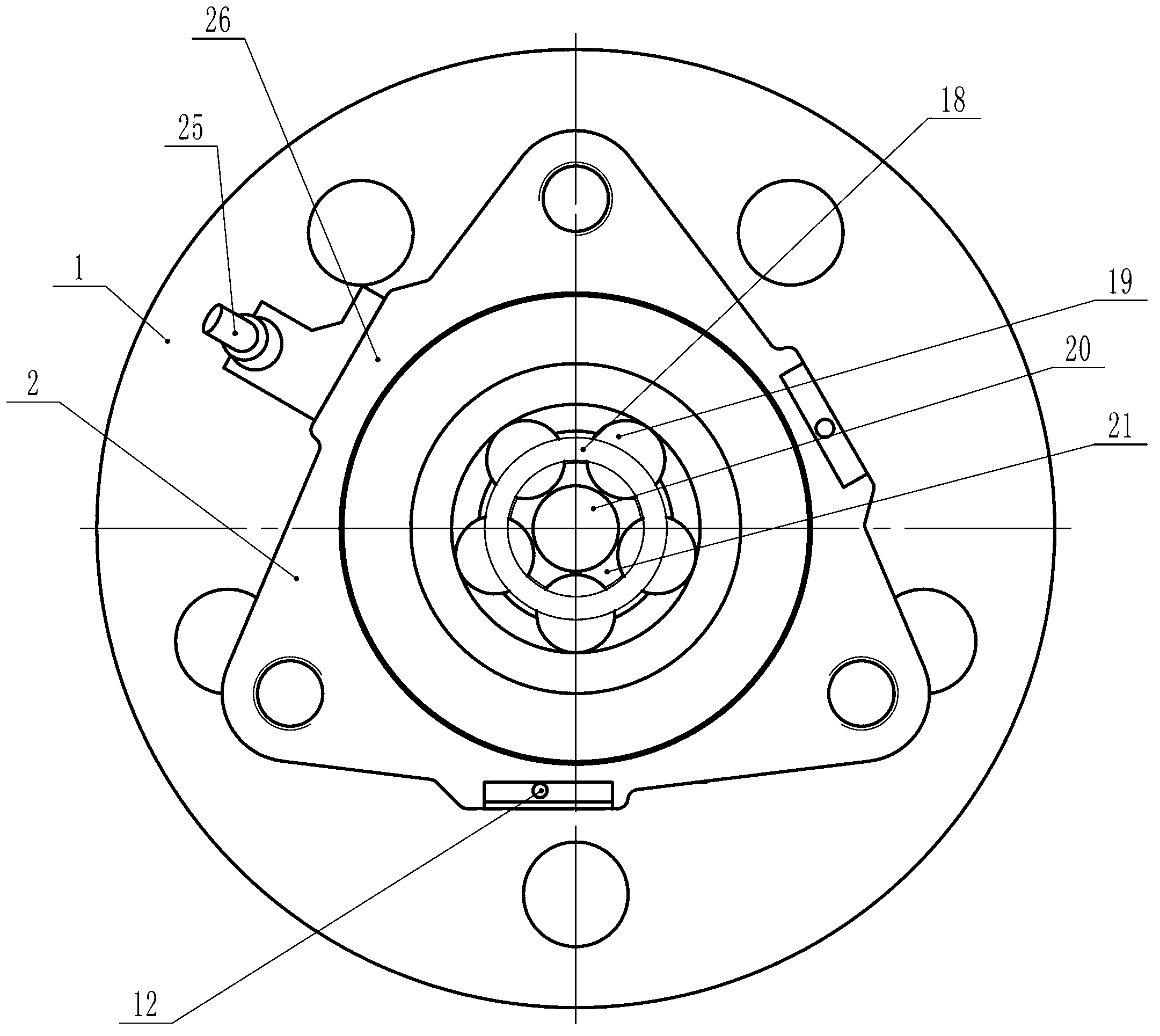

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] see Figure 1-3 , this embodiment is mainly composed of four parts: double row bearing part, constant velocity universal joint part, film temperature, acceleration sensor part and ABS wheel speed sensor part, and the parts include mandrel 1, outer ring 2, counter pressure cover 3, Sealing ring 4, end cover 5, rolling element 6, small inner ring 7, buckle 8, O-ring 9, O-ring 10, cage 11, thin-film temperature / vibration acceleration sensor 12, retaining ring 13, end Cover 14, sealing ring 15, sealing ring 16, sealing end cover 17, cage 18, universal joint rolling element 19, half shaft 20, star sleeve 21, hub bolt 22, rolling element 23, wheel speed sensor ring gear 24 , wheel speed sensor 25, etc., the connection relationship and working principle of each part are detailed below.

[0023] The mandrel 1 has an inner hole, and the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com