Synchronizer jointing tooth for car

A technology of synchronizers and engaging teeth, which is applied in the direction of clutches, mechanically driven clutches, mechanical equipment, etc., which can solve the problems of short meshing length between engaging teeth and inner teeth of the gear sleeve, the existence of risks in use, and unstable cooperation, etc., so as to improve the stability of meshing performance, ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

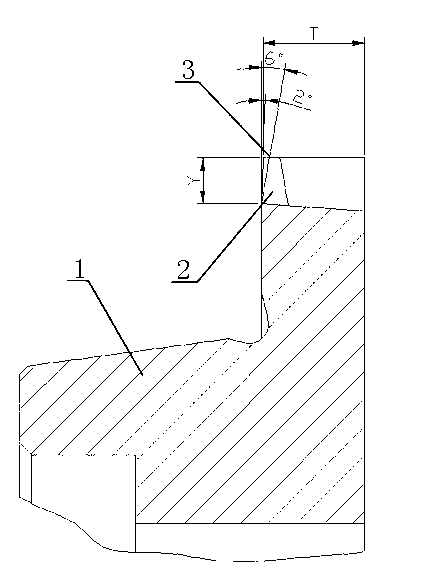

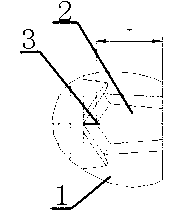

[0010] figure 1 , 2 As shown, a synchronizer engaging tooth for a car includes a ferrule 1 and a plurality of external teeth 2 arranged in the axial direction of the ferrule and evenly distributed on the outer peripheral wall of the ferrule. The outer end surface of one side of the external teeth 2 forms a cutting edge. The blade inclination angle 3 at the edge of the outer end surface of the outer tooth side is 1-5°. In the figure: T is the meshing length of the engaging teeth, and Y is the tooth height. When the blade inclination angle 3 at the locking angle of the outer teeth is 2o, the meshing length T is increased (tan6-tan2)Y=0.07Y compared to 6o.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com