Patents

Literature

32results about How to "Improve mesh stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

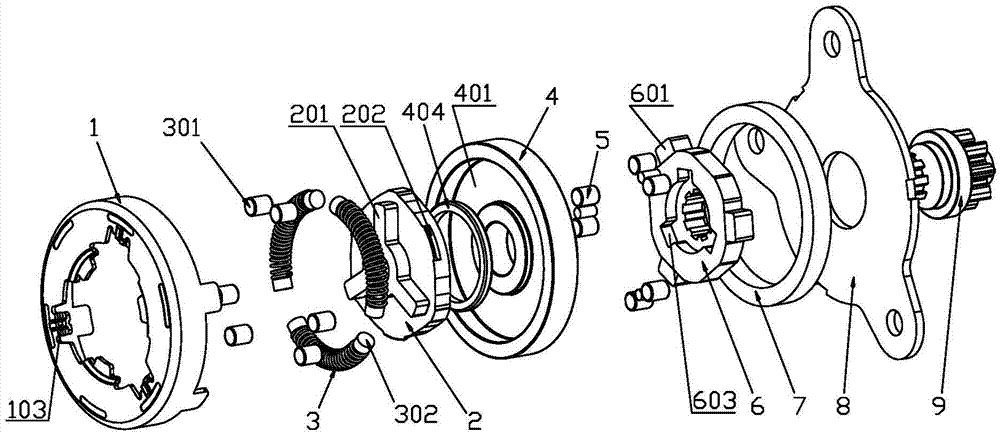

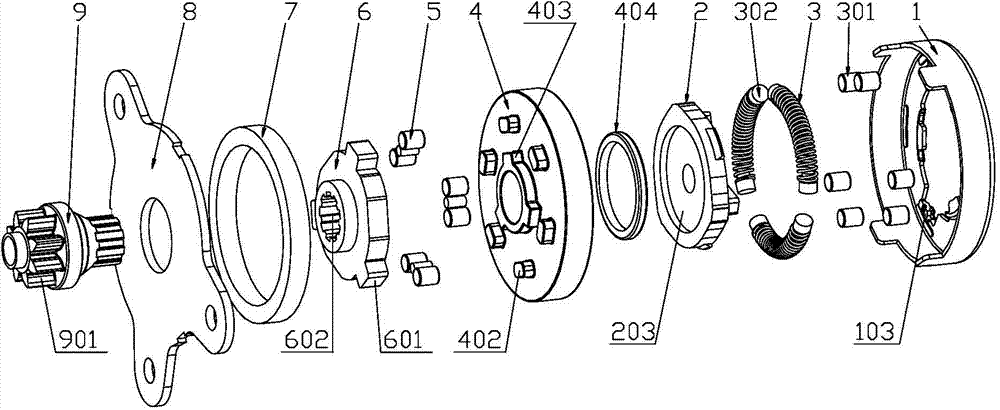

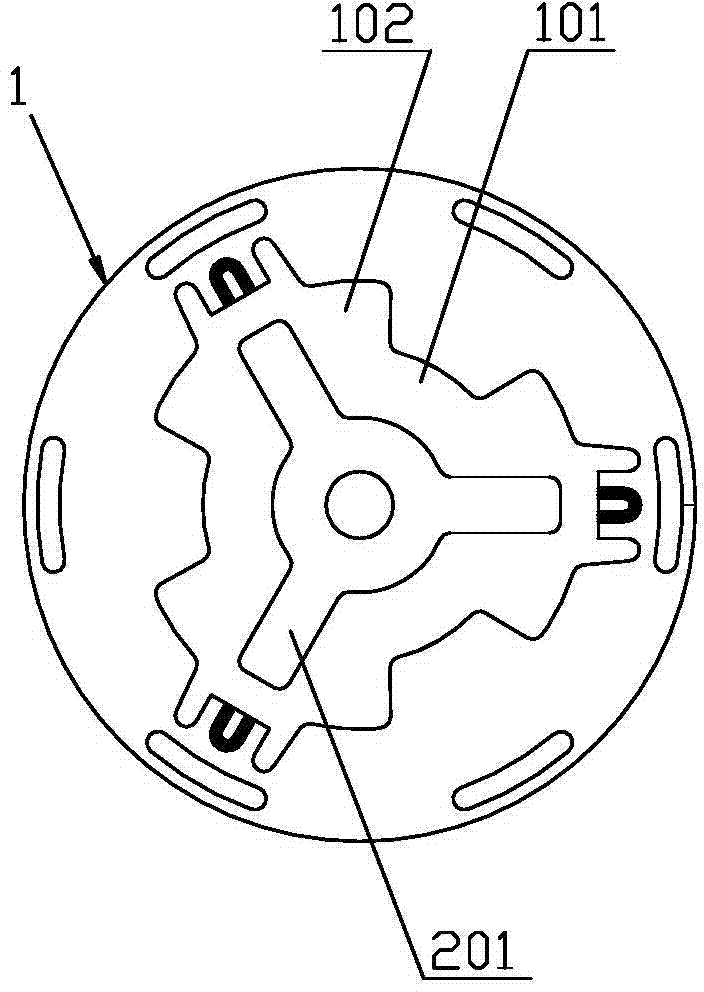

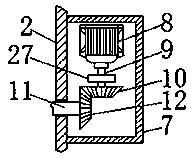

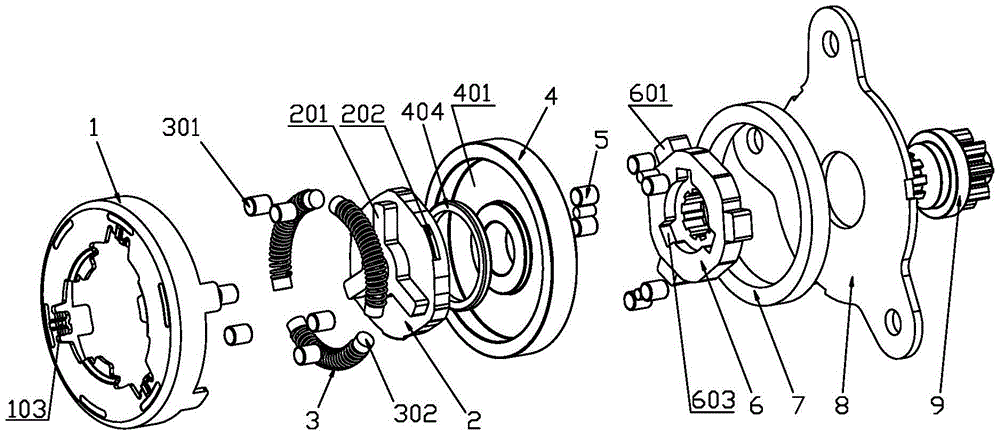

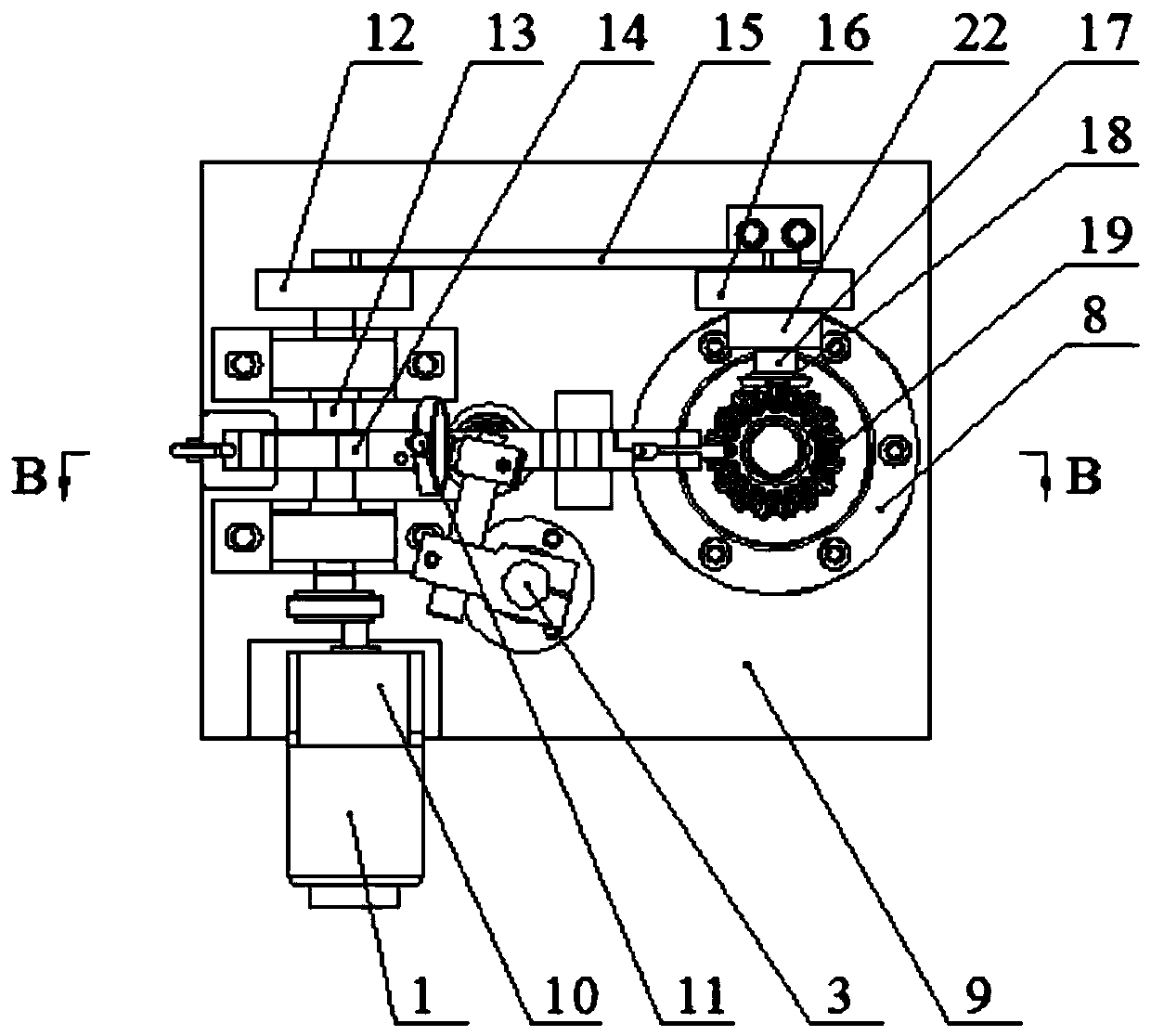

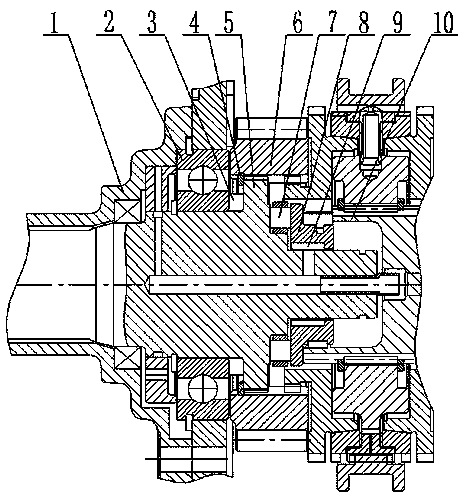

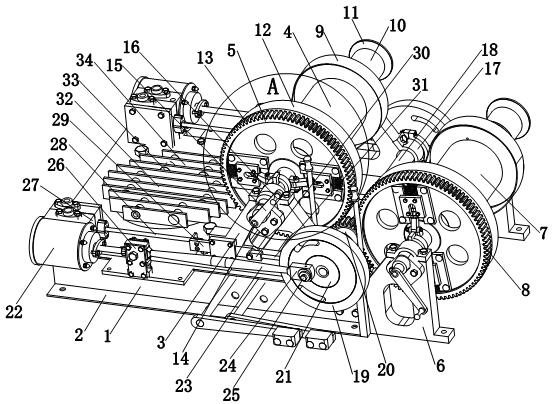

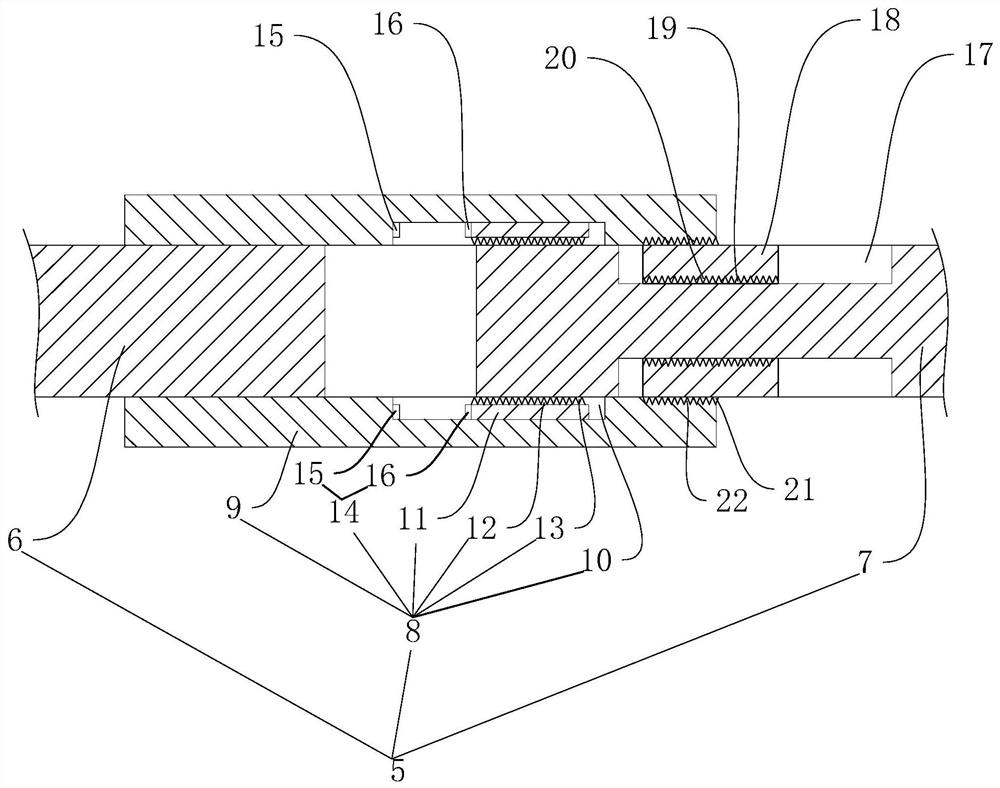

Height-regulating mechanism of vehicle seat

InactiveCN104723910AEasy to unlockReliable two-way self-lockingMovable seatsWork performanceSelf locking

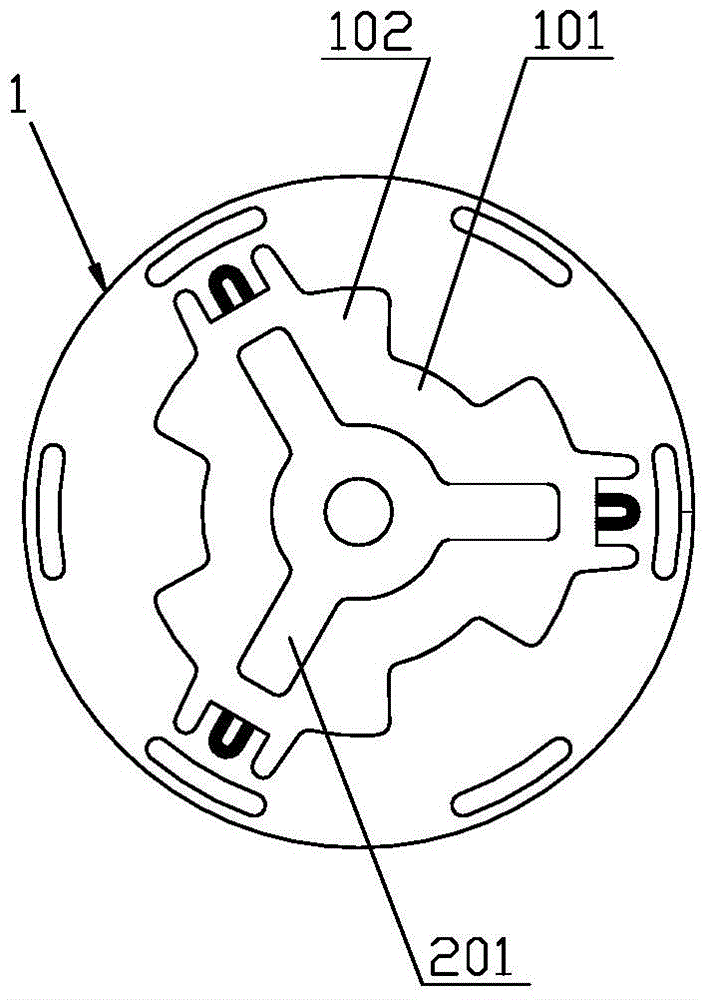

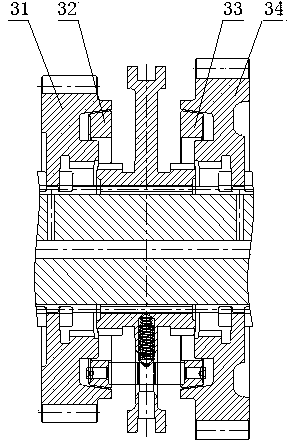

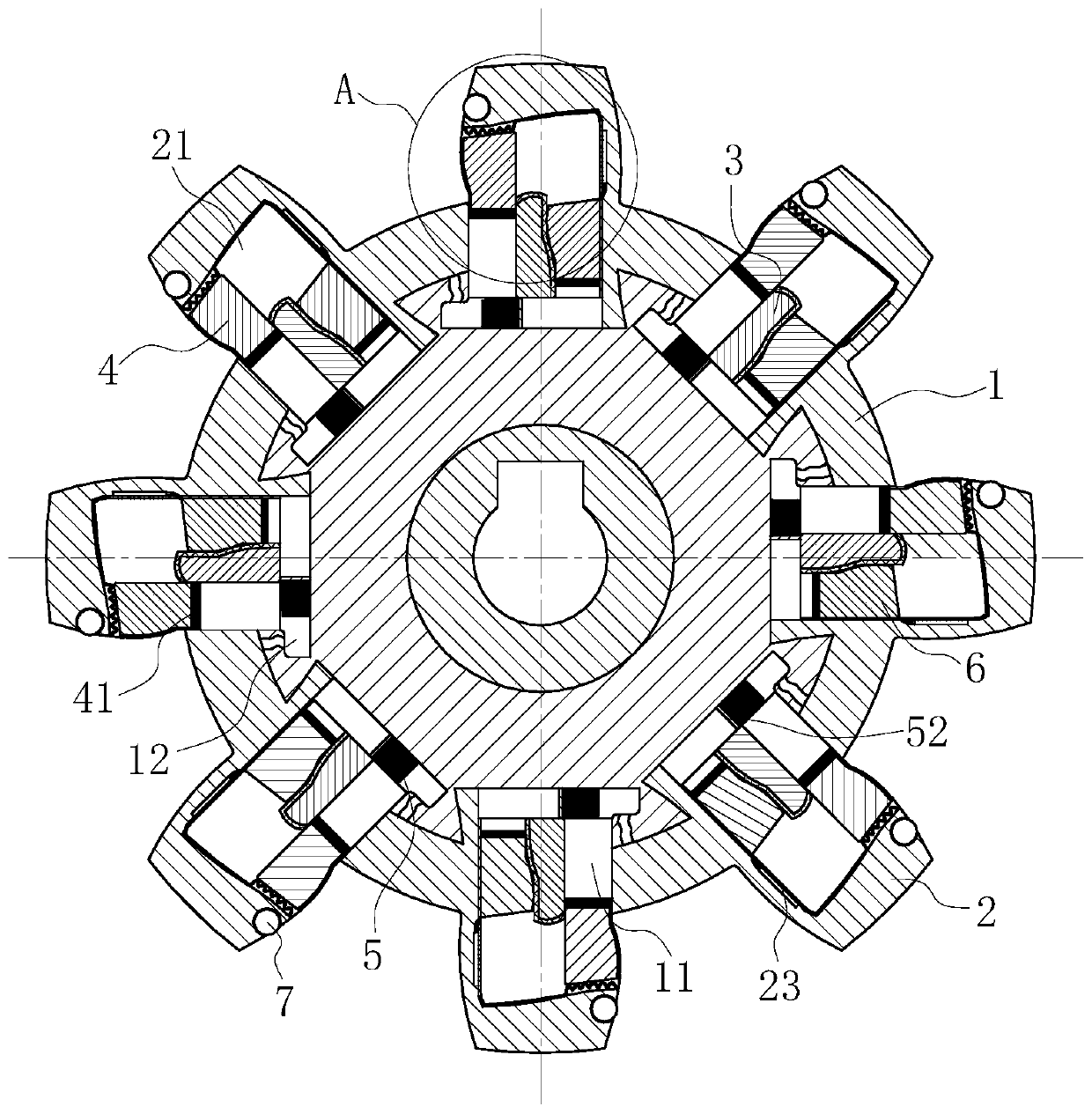

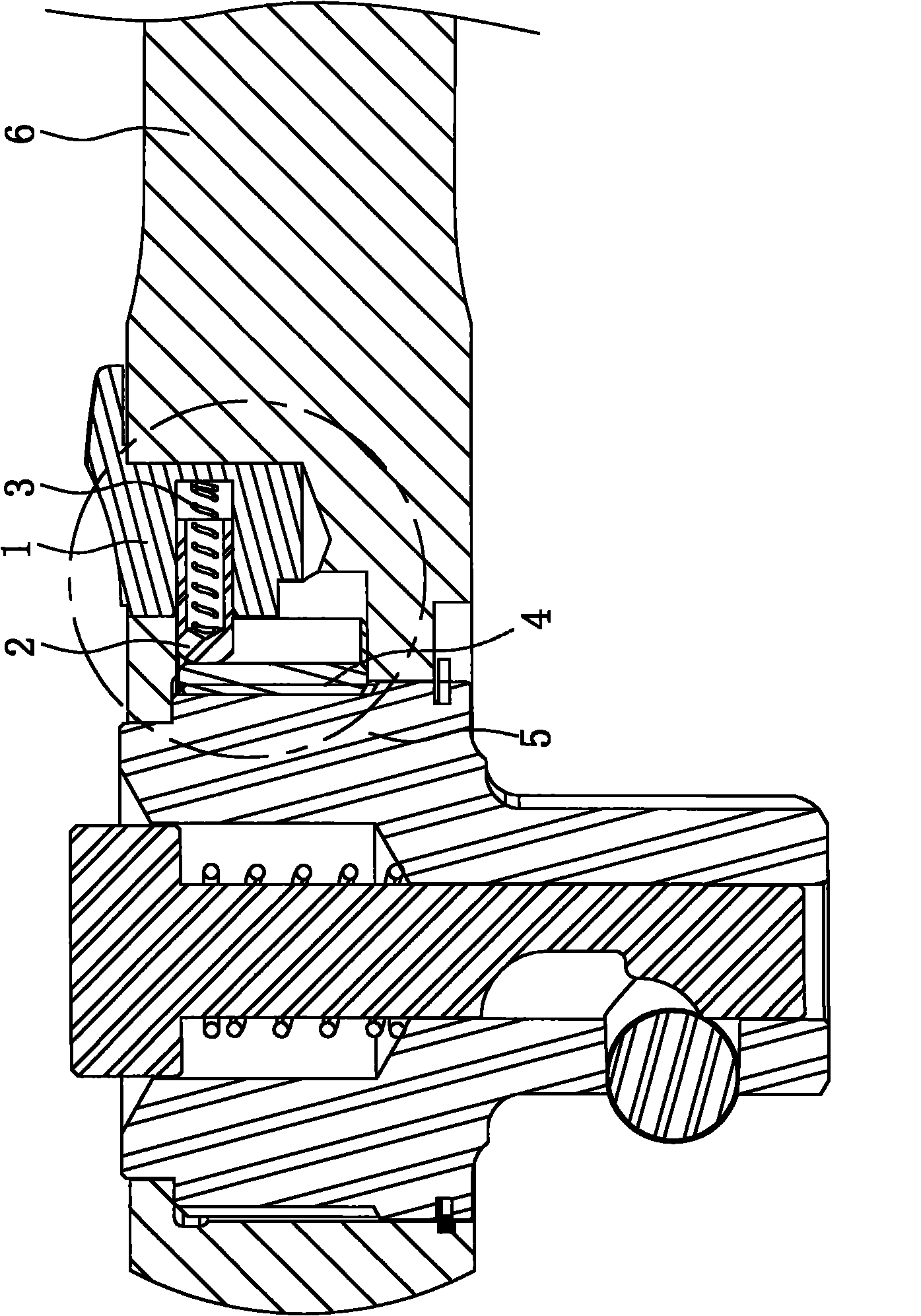

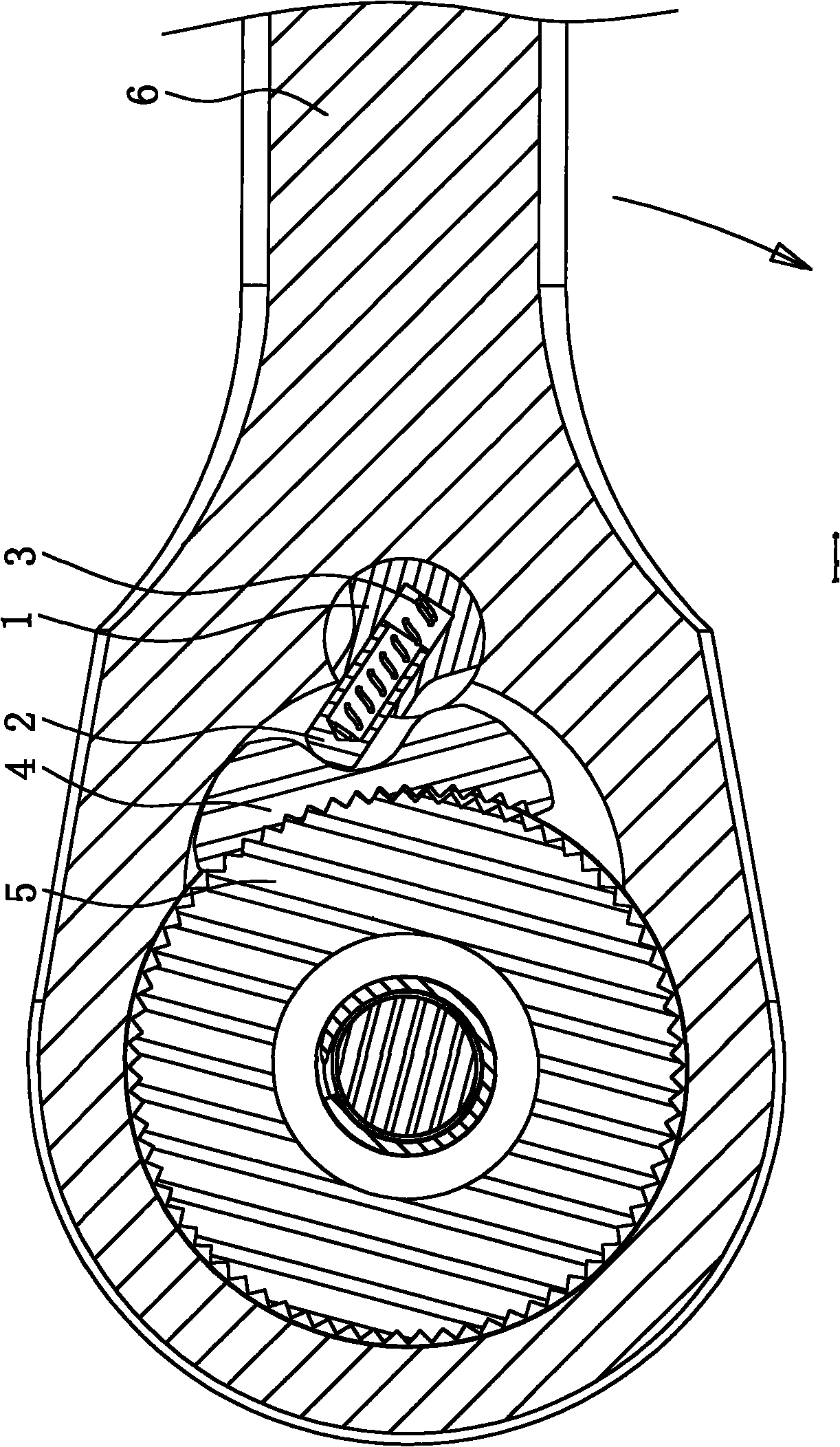

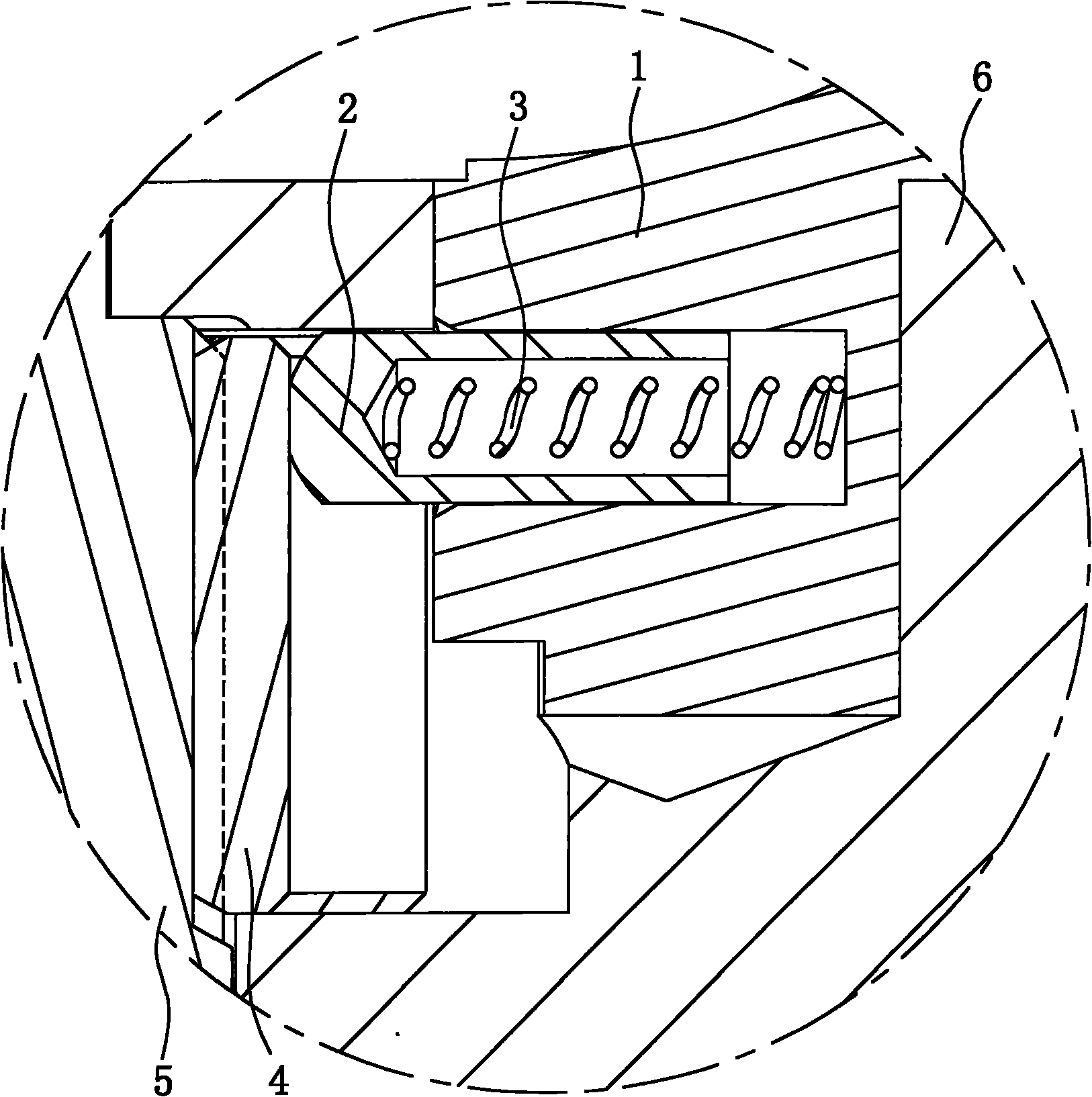

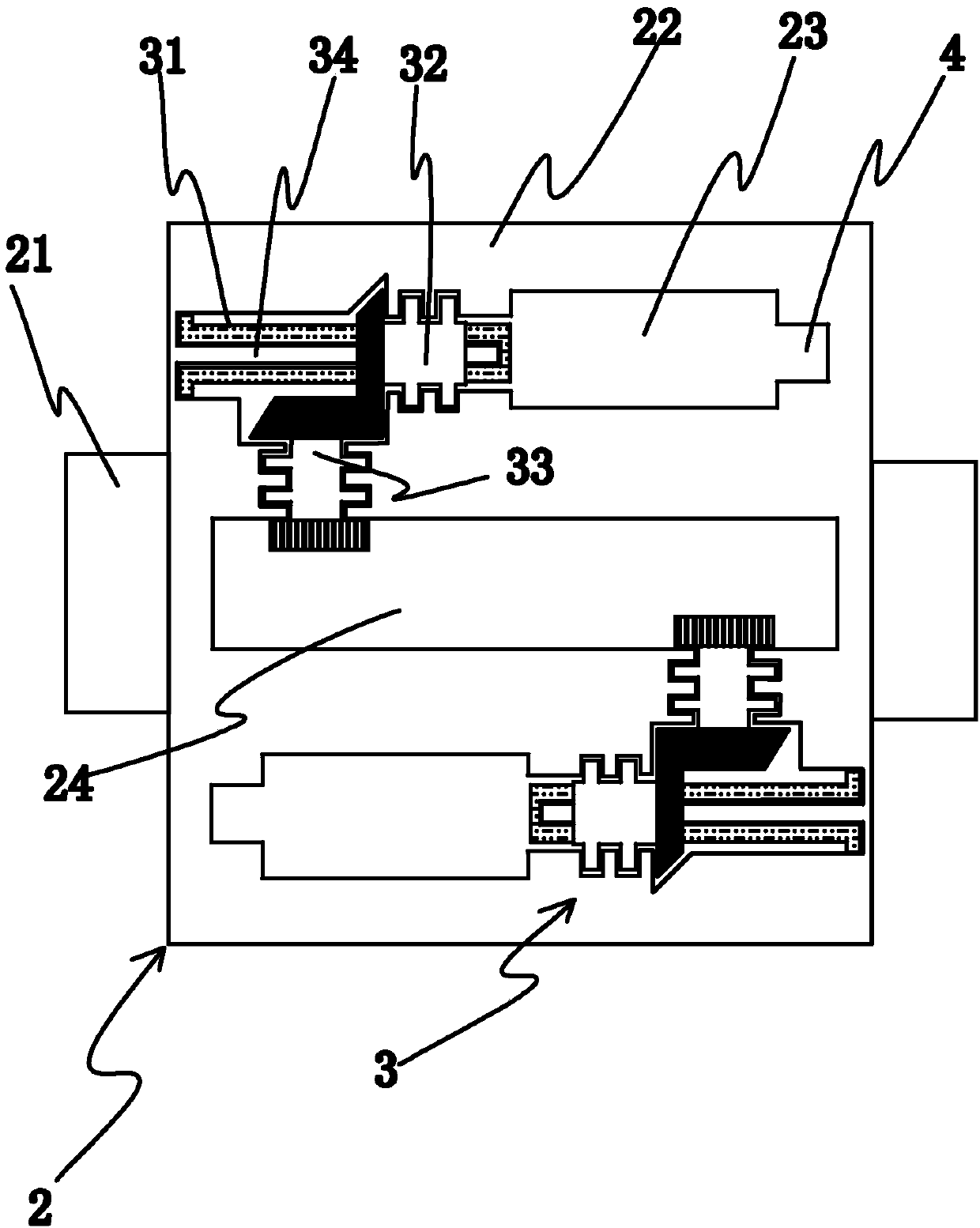

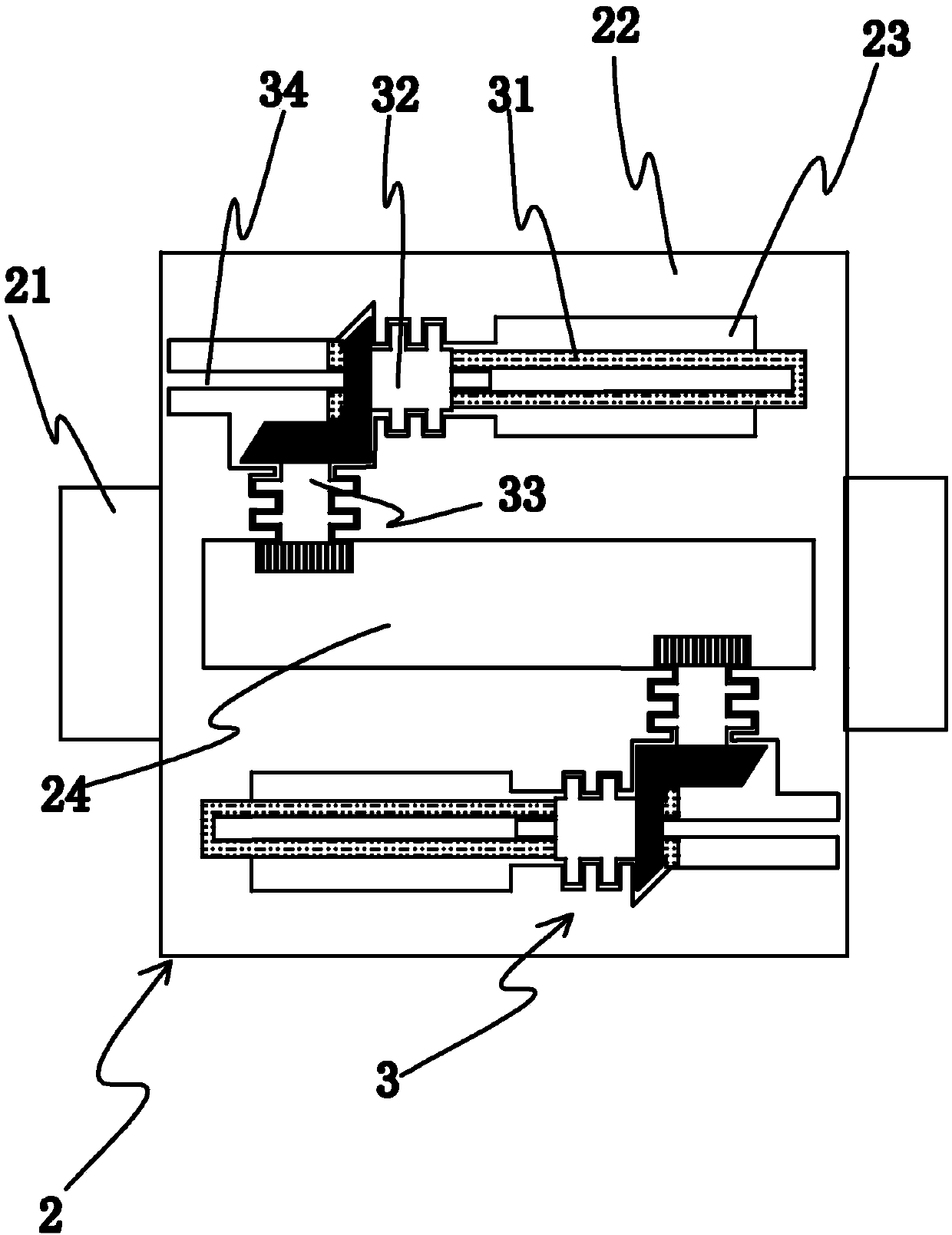

The invention provides a height-regulating mechanism of a vehicle seat. The height-regulating mechanism of the vehicle seat comprises a first bidirectional overrunning clutch and a second bidirectional overrunning clutch which use a pusher dog disc in common. The first bidirectional overrunning clutch comprises a first transmission star wheel, the outer side surface of the first transmission star wheel comprises three sections of first arc surfaces and three sections of second arc surfaces which are arranged circumferentially at intervals, and one first arc surface and one second arc surface are connected through a first arc wedge surface. Springs are respectively arranged between one first arc surface and a circular groove wheel of the pusher dog disc, and two ends of each spring is provided with a roller which is clamped between the first arc wedge surface and the circular groove wheel. The second bidirectional overrunning clutch comprises a second transmission star wheel, the outer side surface of the second transmission star wheel comprises three sections of third arc surfaces and three sections of planes which are arranged circumferentially at intervals, and a third arc surface is connected with the planes through a second arc wedge surface. A pin roller which is clamped between the second arc wedge surface and the inner side surface of the output end shell under the function of an elastic element is arranged between each pusher dog of the pusher dog disc. The height-regulating mechanism of the vehicle is good in self-locking performance, stable in working performance, and high in control precision.

Owner:上海交运汽车精密冲压件有限公司

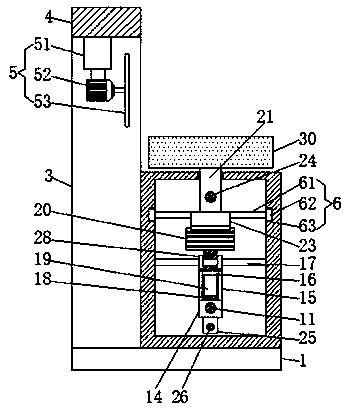

Cable processing cutting device capable of fixing workpiece conveniently

The invention discloses a cable processing cutting device capable of fixing a workpiece conveniently. The device comprises a bottom plate, a placing box is fixedly connected to the front side of the top of the bottom plate, supporting columns are fixedly connected with the two sides of the back surface of the placing box, a bearing plate is arranged at the tops of the supporting columns, the bottom of the supporting plate is fixedly connected with the tops of the supporting columns, and a cutting mechanism located between the supporting columns is fixedly connected to the bottom of the bearingplate. Through joint effects of a first motor, a first bevel gear, a second bevel gear, a positive and negative tooth lead screw, a thread sleeve, a rotating plate, a semi-gear, a toothed plate, a positioning rod, a clamping plate and a clamping block, the problem that an existing cutting machine in the current market cannot conveniently fix cables when the cables are cut is solved, the cable processing cutting device capable of conveniently fixing the workpiece has the advantage that the cables can be fixed and cut conveniently, avoids the problems that the cables need to be clamped througha hand rocking mode, the clamping speed is low, and the clamping effect is poor, and improves the cutting efficiency.

Owner:ANHUI HUANENG CABLE GRP

car seat height adjustment mechanism

InactiveCN104723910BEasy to unlockReliable two-way self-lockingMovable seatsWork performanceEngineering

The invention provides a height-regulating mechanism of a vehicle seat. The height-regulating mechanism of the vehicle seat comprises a first bidirectional overrunning clutch and a second bidirectional overrunning clutch which use a pusher dog disc in common. The first bidirectional overrunning clutch comprises a first transmission star wheel, the outer side surface of the first transmission star wheel comprises three sections of first arc surfaces and three sections of second arc surfaces which are arranged circumferentially at intervals, and one first arc surface and one second arc surface are connected through a first arc wedge surface. Springs are respectively arranged between one first arc surface and a circular groove wheel of the pusher dog disc, and two ends of each spring is provided with a roller which is clamped between the first arc wedge surface and the circular groove wheel. The second bidirectional overrunning clutch comprises a second transmission star wheel, the outer side surface of the second transmission star wheel comprises three sections of third arc surfaces and three sections of planes which are arranged circumferentially at intervals, and a third arc surface is connected with the planes through a second arc wedge surface. A pin roller which is clamped between the second arc wedge surface and the inner side surface of the output end shell under the function of an elastic element is arranged between each pusher dog of the pusher dog disc. The height-regulating mechanism of the vehicle is good in self-locking performance, stable in working performance, and high in control precision.

Owner:上海交运汽车精密冲压件有限公司

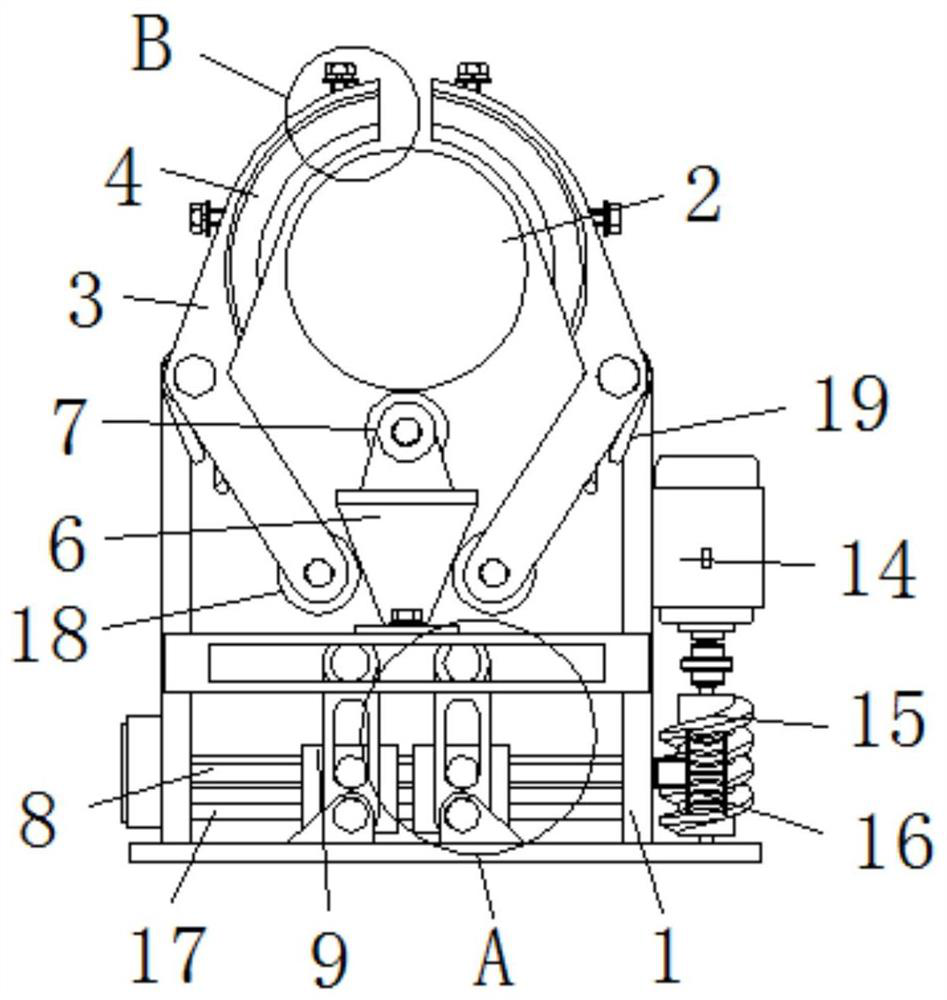

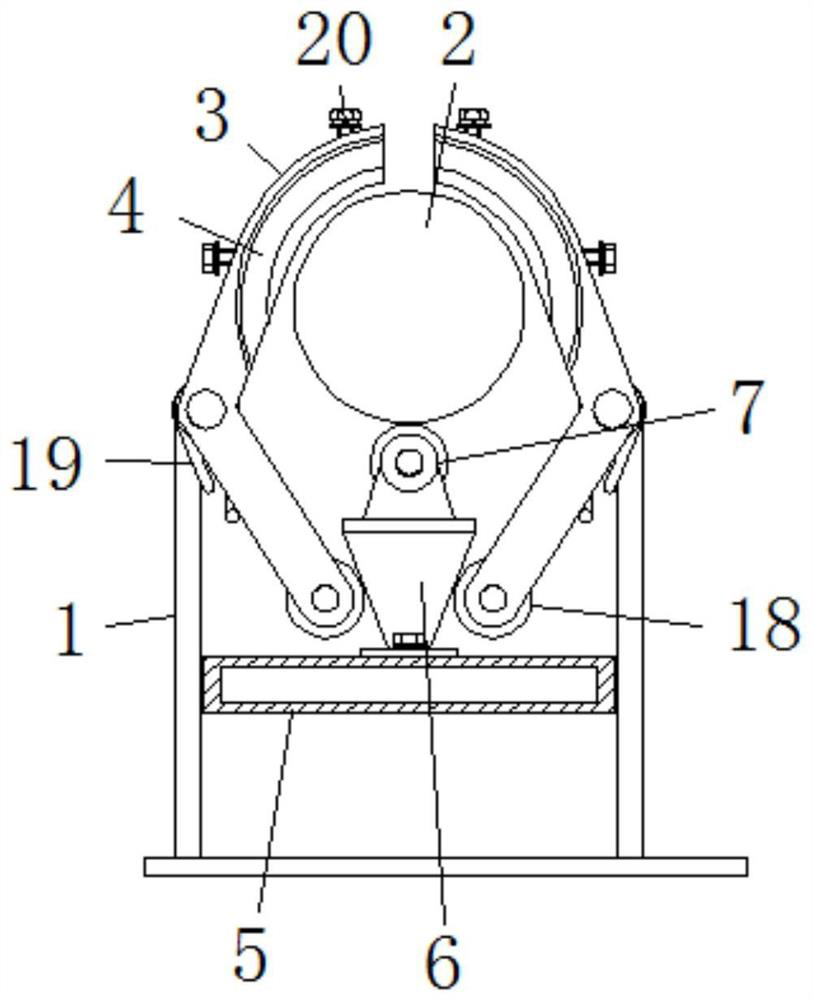

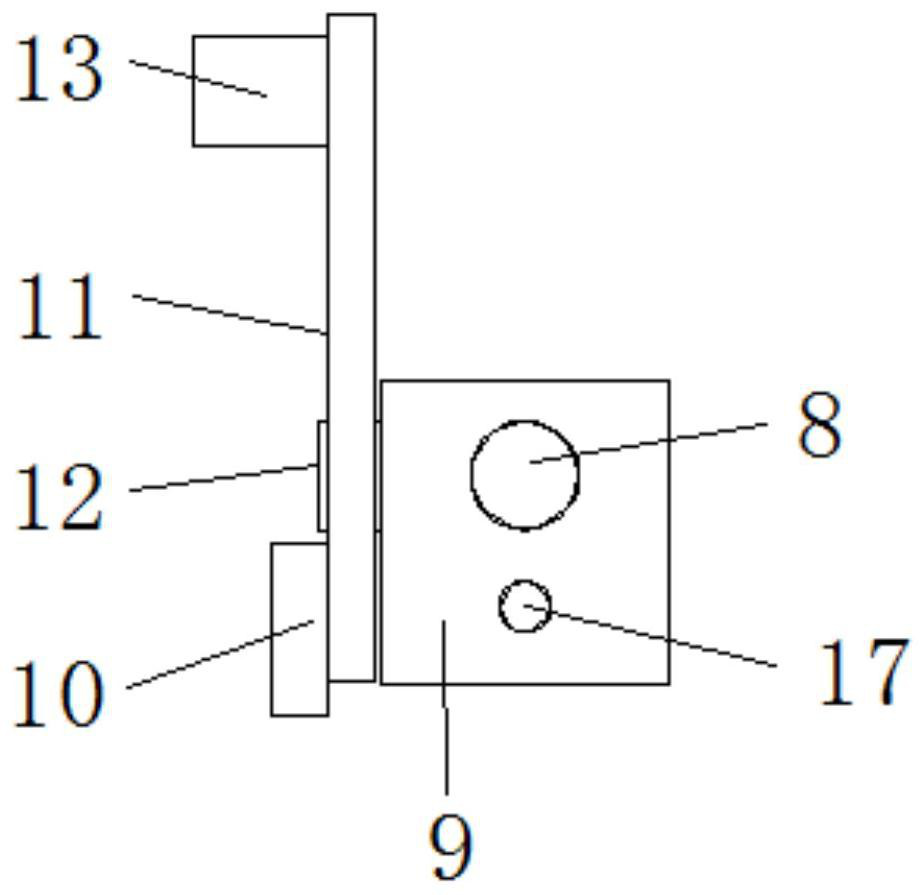

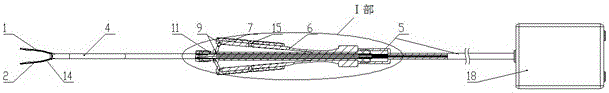

Double-curvature profile bending machine

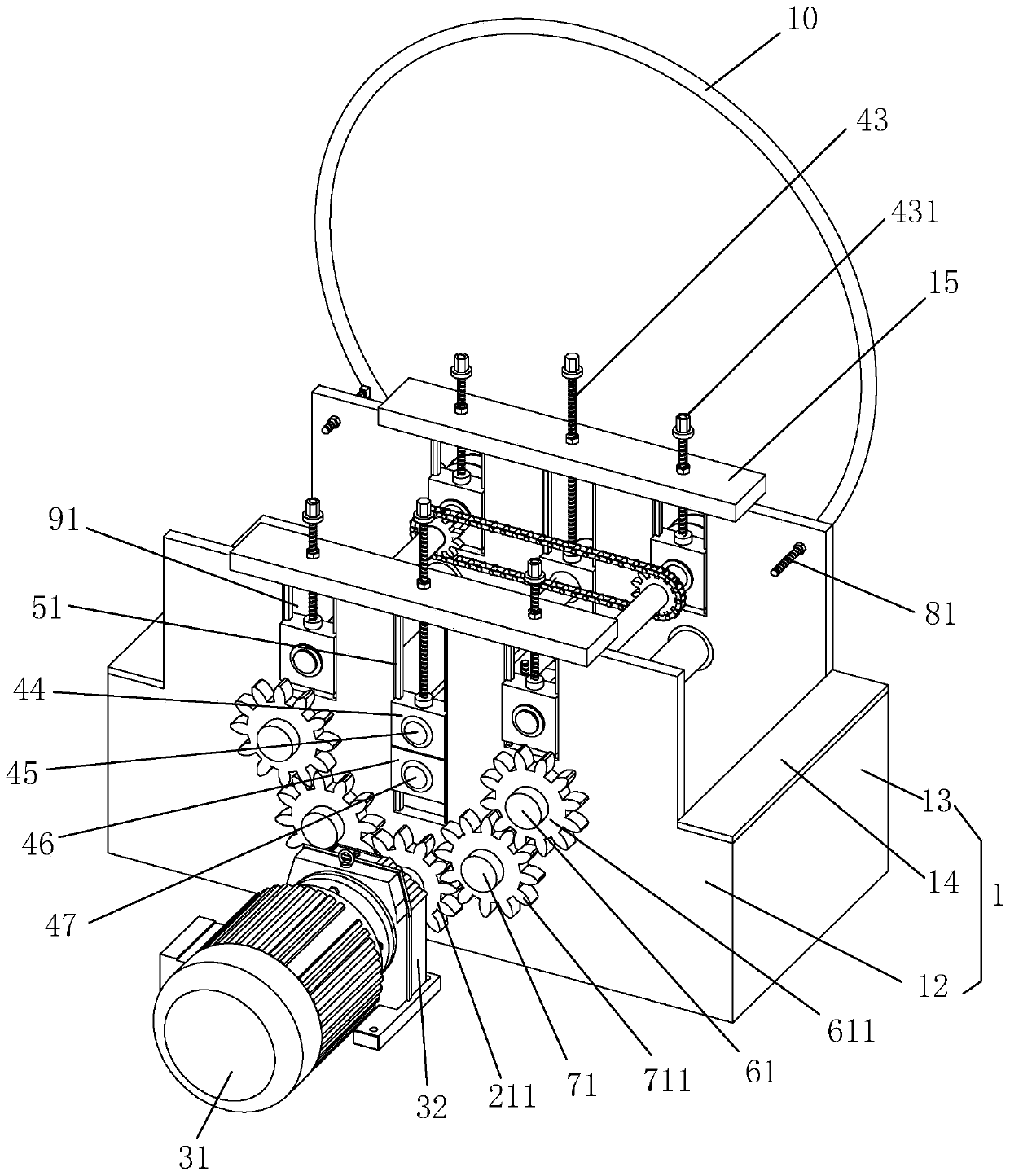

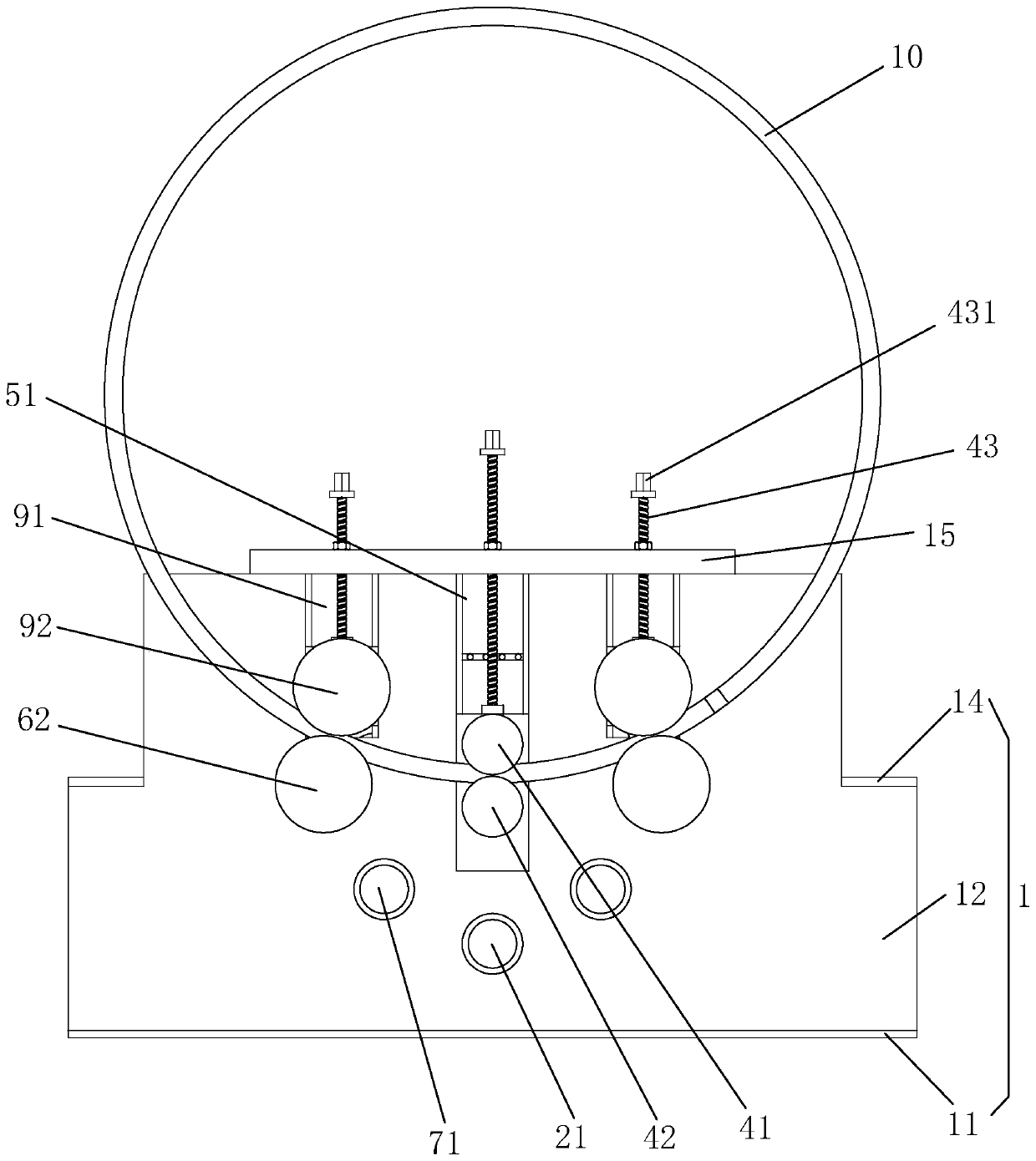

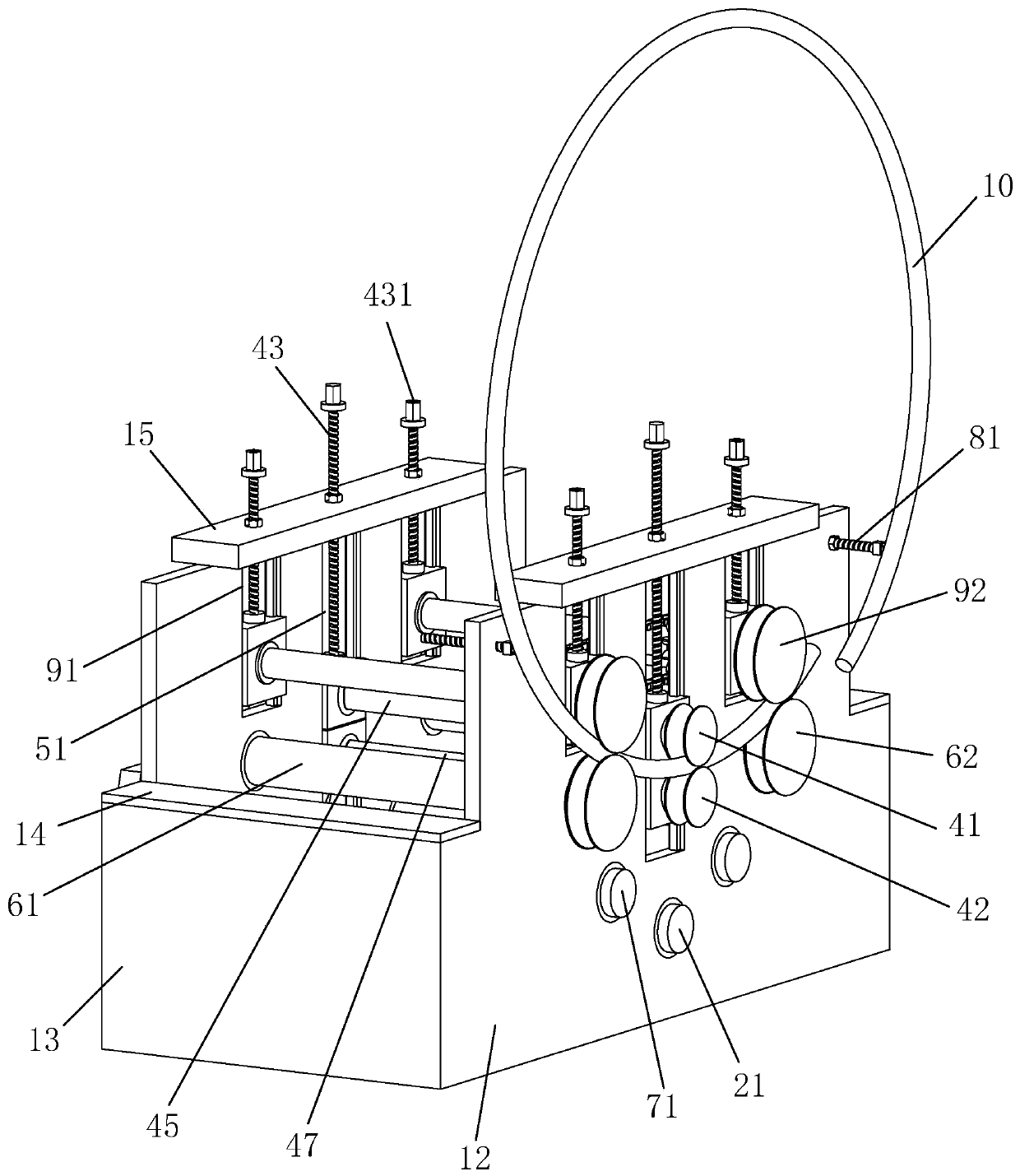

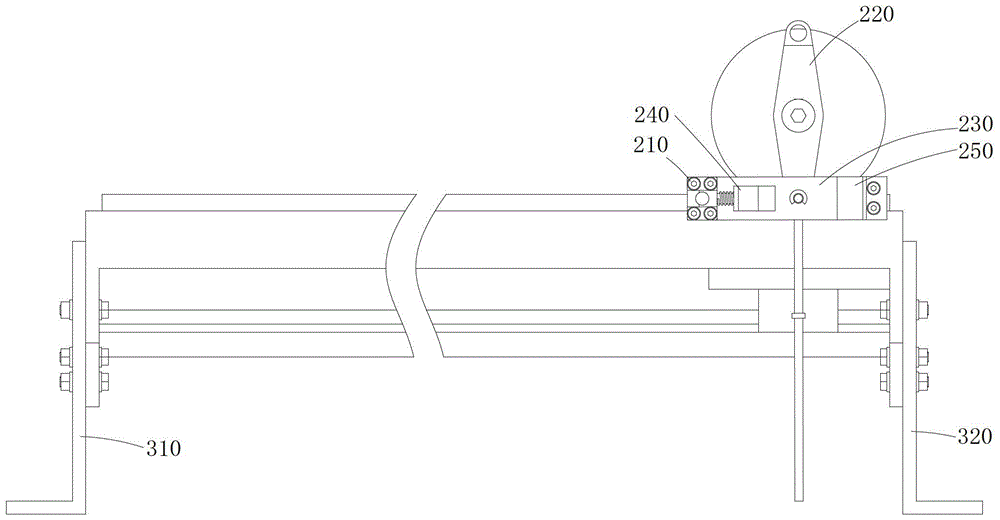

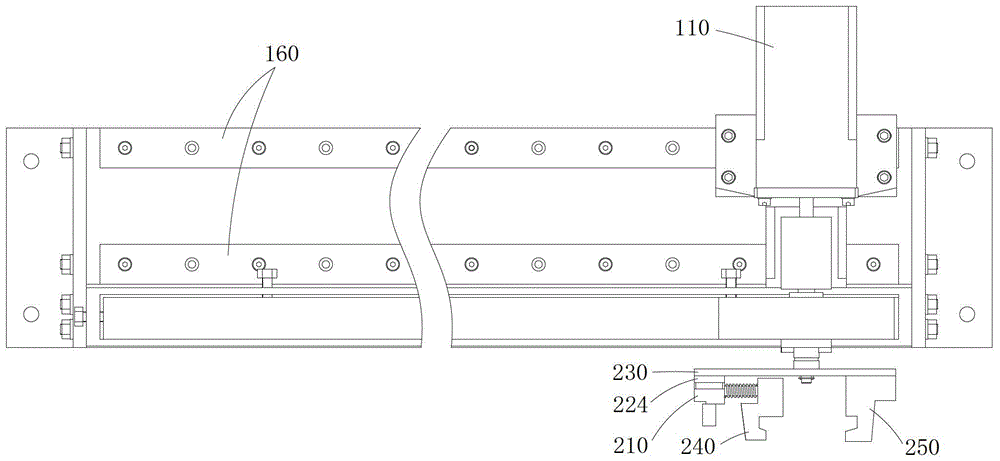

ActiveCN109909339ARealize support and conveyGuaranteed stabilityMetal-working feeding devicesPositioning devicesDrive shaftEngineering

The invention particularly relates to a double-curvature profile bending machine, which comprises a rack, a feeding assembly, a forming assembly, an outward-pushing assembly and a power device. The feeding assembly comprises two driven shafts, one ends of the driven shafts penetrate out of the rack and then are coaxially and fixedly connected with driven die wheels, the power device drives the driven shafts to rotate, the forming assembly comprises an upper pressing wheel arranged on the rack in the mode of being capable of ascending and descending, and a lower pressing wheel which is locatedunder the upper pressing wheel and is adjustable in height, and the two driven die wheels are symmetrically distributed on the two sides of the upper pressing wheel and the lower pressing wheel; a gapfor allowing a profile to penetrate is reserved between the upper pressing wheel and the lower pressing wheel; and two second sliding blocks are slidably arranged on the rack, a second rotating shaftis rotationally connected between the two second sliding blocks, the lower pressing wheel is coaxially and fixedly connected to one end of the second rotating shaft and located on the side, away fromthe rack, of the second sliding block, an adjusting device for controlling the height of the lower pressing wheel is arranged on the rack, and the top of the adjusting device is coaxially and fixedlyconnected to the second rotating shaft. The double-curvature profile bending machine realizes the one-machine multi-function effect, and the machining and manufacturing costs are relatively lowered.

Owner:河北华环化工设备制造有限公司

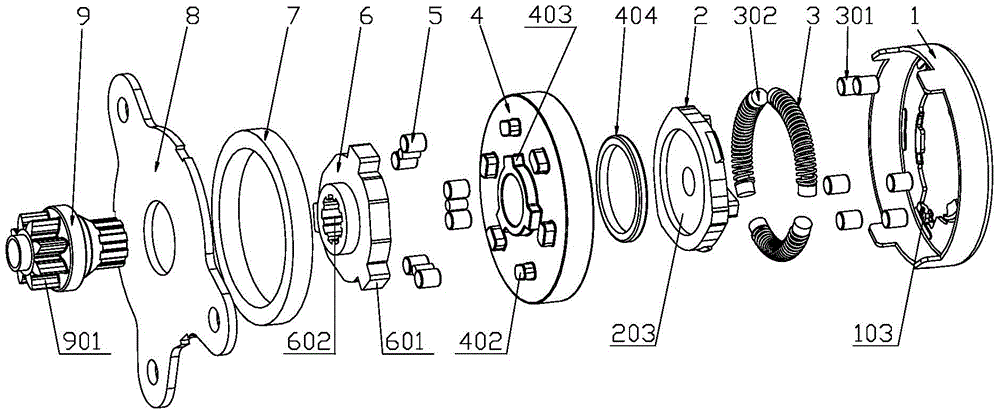

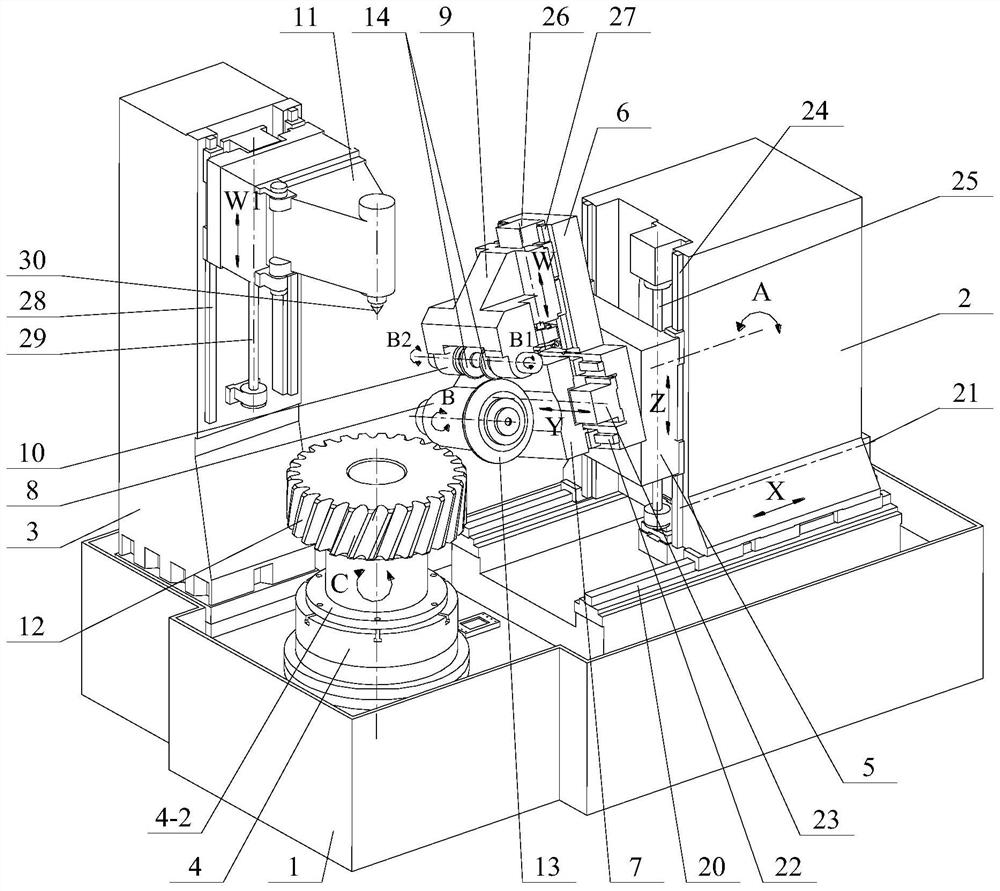

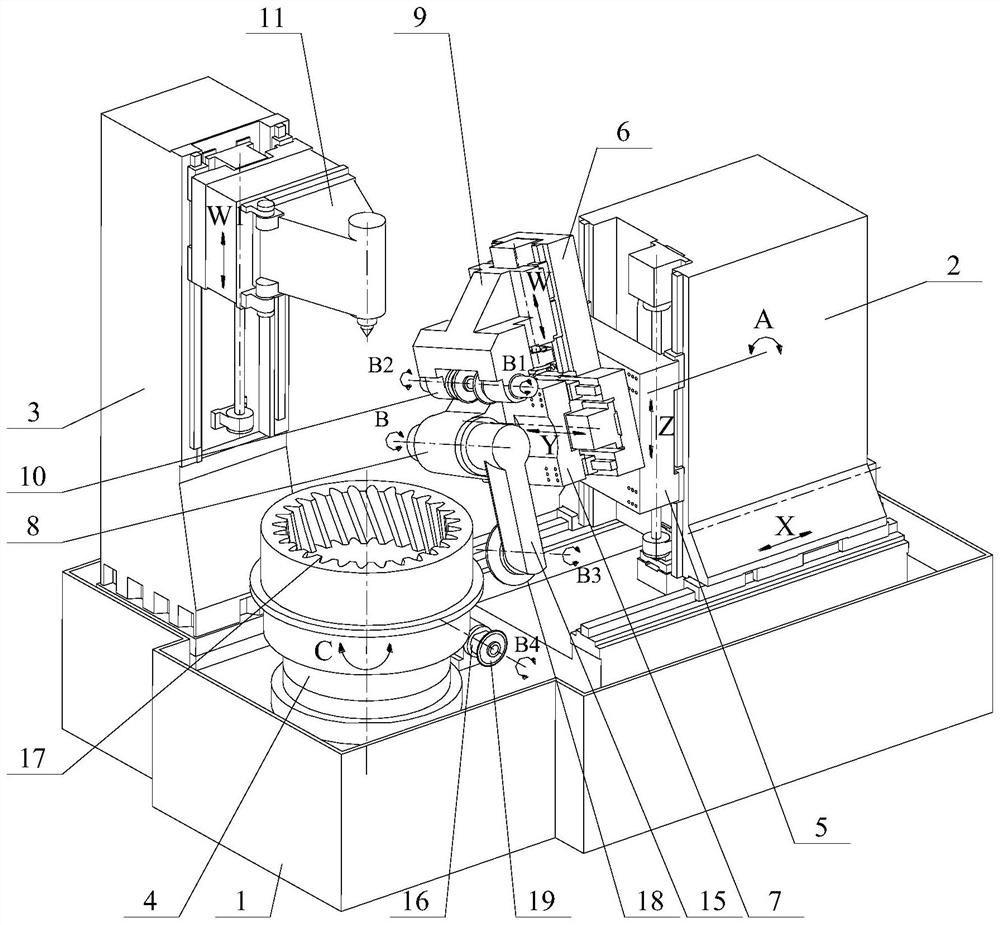

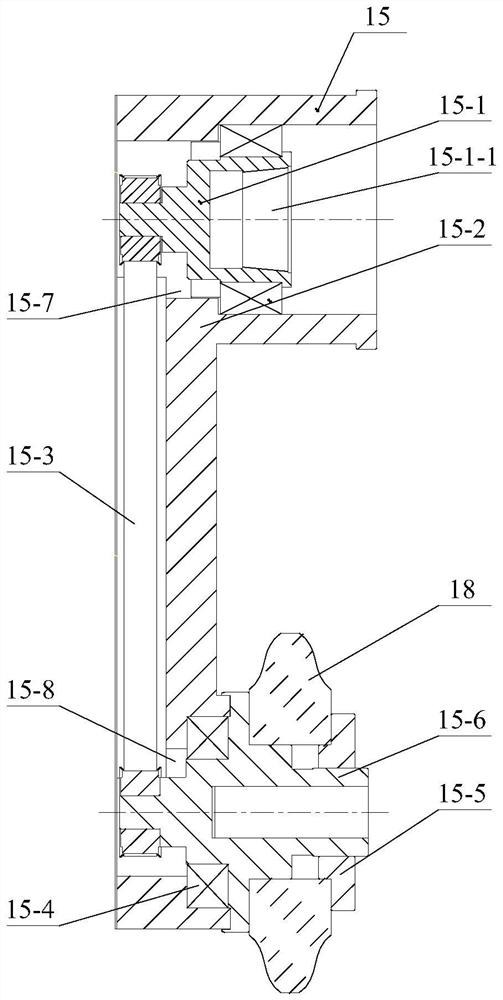

Formed grinding wheel gear grinding machine tool

ActiveCN114226868AReduce wearGood trimming accuracyAbrasive surface conditioning devicesLarge fixed membersGear grindingTeeth grinding

A Z-axis sliding table of the gear grinding machine tool is arranged on a stand column and can move along the Z axis relative to the stand column, an A-axis rotary table of the gear grinding machine tool is arranged on the Z-axis sliding table and can rotate around the A axis relative to the Z-axis sliding table, and a Y-axis sliding table of the gear grinding machine tool is arranged on the A-axis rotary table and can move along the Y axis relative to the A-axis rotary table. A W-axis sliding table is arranged on an A-axis rotary table and can move along a W axis relative to the A-axis rotary table; the grinding wheel spindle box is arranged on the Y-axis sliding table, and an outer tooth grinding wheel is detachably arranged on the grinding wheel spindle box. An outer tooth dressing spindle box is arranged on the W-axis sliding table, and an outer tooth dressing grinding wheel is arranged at the power output end of the outer tooth dressing spindle box; the Z axis is the grinding feeding direction, the X axis is the grinding feeding and retracting direction, the Y axis is the displacement direction of the grinding wheel spindle box along the axis of the grinding wheel spindle box, and the W axis is the direction in which the external tooth dressing grinding wheel is close to or far away from the external tooth grinding wheel in the radial direction of the external tooth grinding wheel. By applying the scheme, the machining precision and the grinding efficiency can be effectively improved.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

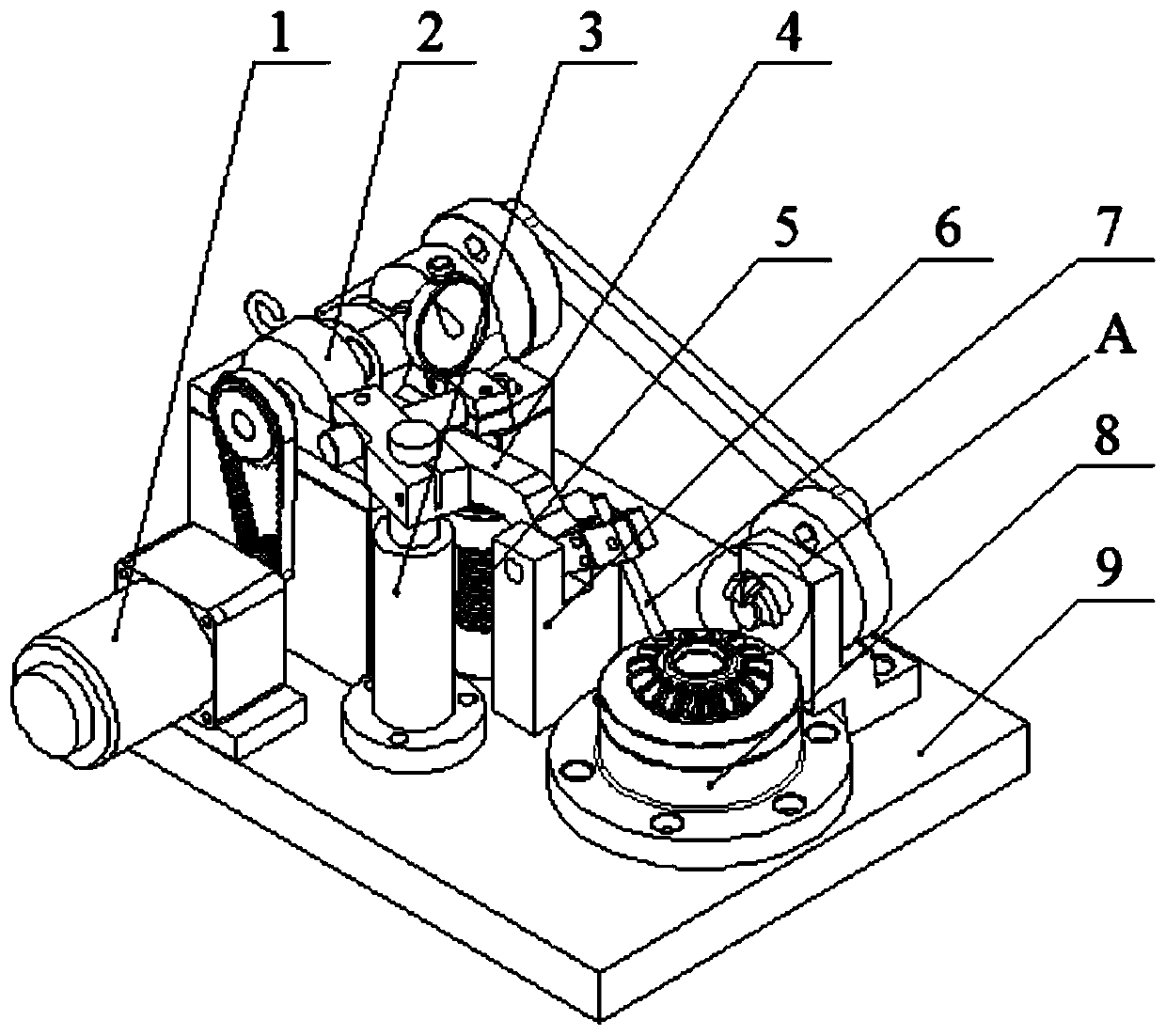

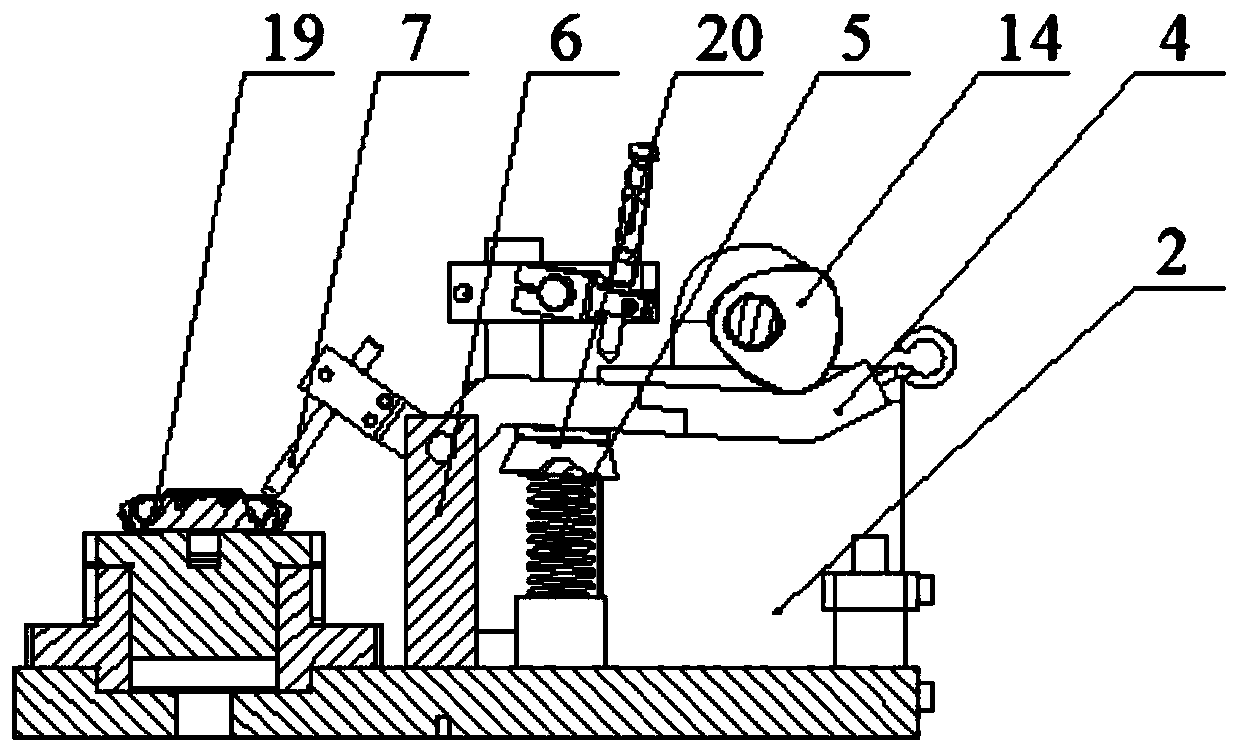

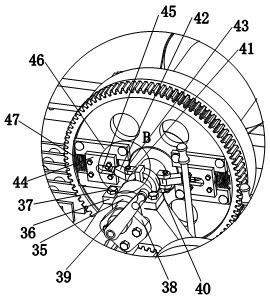

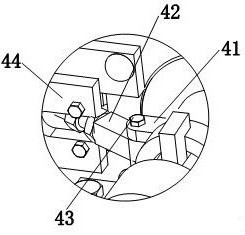

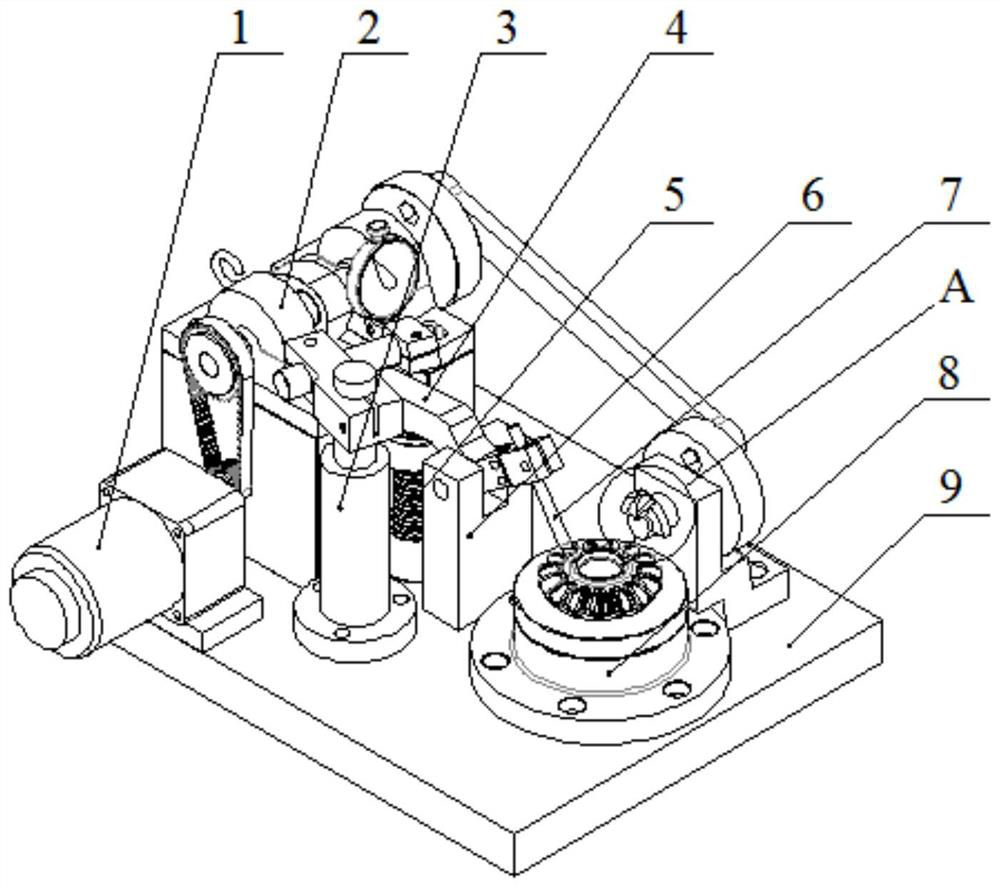

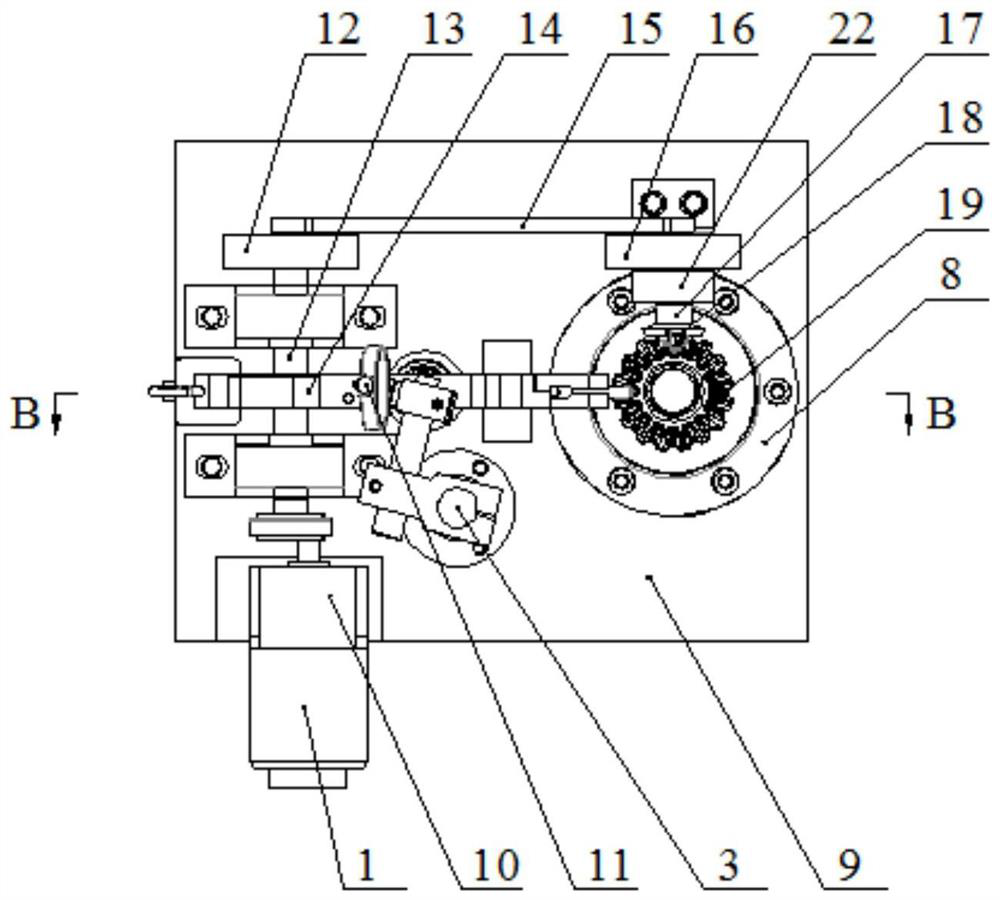

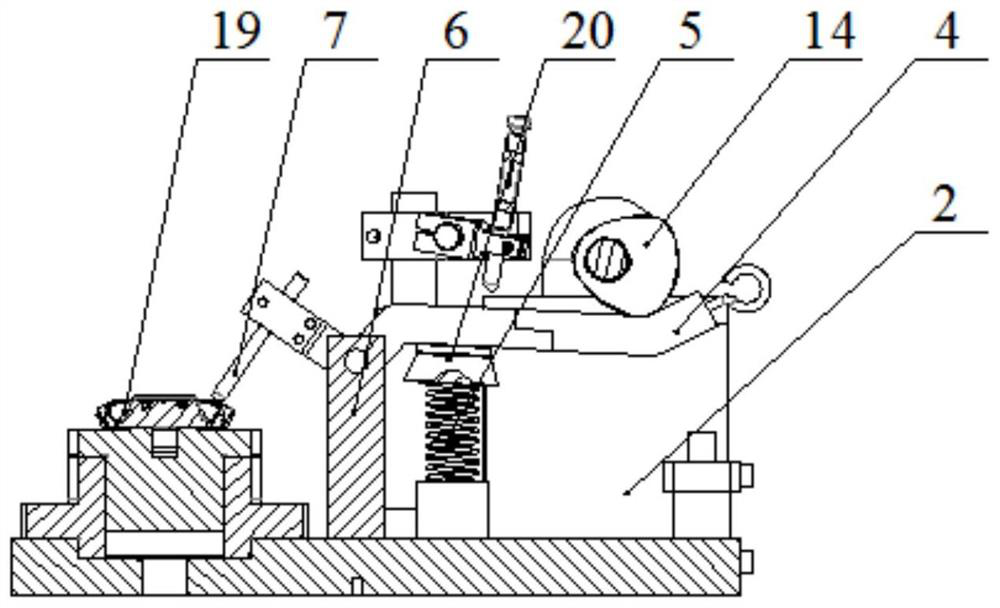

Automobile bevel gear automatic detecting and bouncing device

ActiveCN110375607ASolve the problem that detection is susceptible to light interferenceHighly creativeMechanical measuring arrangementsGear wheelGear tooth

The invention relates to an automobile bevel gear automatic detecting and bouncing device. The device comprises a pedestal, a shaft support, a curved rod support and a gear support, wherein the shaftsupport, the curved rod support and the gear support are successively and fixedly arranged on the pedestal. An eccentric wheel is rotatably installed in the shaft support. A curved rod is rotatably installed on a top of the curved rod support, one end of the curved rod is slidably cooperated with an outer circumference of the eccentric wheel, and the other end of the curved rod is fixedly providedwith a detecting rod. One side of the shaft support is connected with a power unit providing rotational power to the eccentric wheel, and the other side of the shaft support is connected with a transmission unit providing rotational power for a gear to be detected on the gear support. A dial indicator for detecting a swinging limit of the curved rod and a reset spring for providing reset supportfor the curved rod are installed on the pedestal. The detecting device solves a problem that precision of manual detection of a gear tooth type is not high in the prior art, and realizes full mechanical transmission and automatic detection of full mechanical calibration at the same time. The device has advantages of low cost, a high detection speed, high detection precision and the like.

Owner:TIANJIN ZENGYIDA PRECISION FORGING GEAR TECH CO LTD

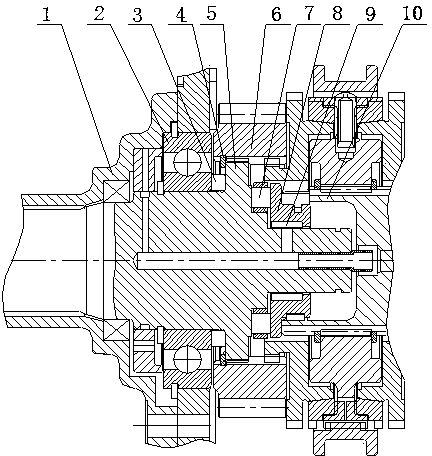

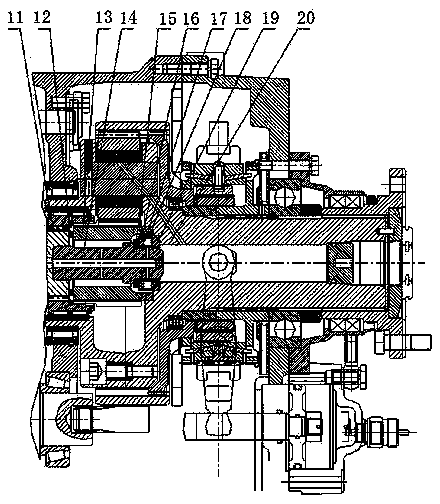

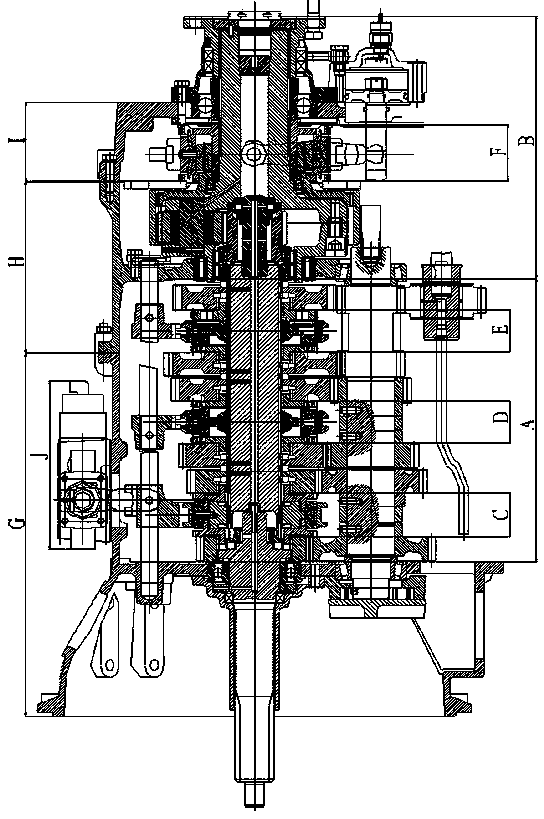

Novel 10-gear double-intermediate-shaft synchronizer gearbox

ActiveCN103388656AImprove gear load capacity and meshing stabilityReduce meshing noiseToothed gearingsGearing detailsEngineeringMechanical engineering

The invention discloses a novel 10-gear double-intermediate-shaft synchronizer gearbox, which comprises a novel three-section shell, an input shaft and a main shaft connected with the input shaft, wherein the main shaft is connected with a sun wheel in a sub-box through a spline taper reduction sleeve, the front end and the rear end of the main shaft are provided with a main shaft front positioning mechanism and a main shaft rear positioning mechanism respectively, the main shaft is also provided with a gear-shifting bevel gear group which comprises five forwarding bevel gears and a reversing bevel gear, a single-cone lock ring synchronizer is arranged between the fourth gear and the fifth gear on the main shaft, a single-cone lock pin synchronizer is arranged between the second gear and the third gear on the main shaft, a twin cone lock pin synchronizer is arranged at the first gear on the main shaft, the sub-box part comprises two gear positions and forms a 5*2 structure of ten forward gears and two reverse gears with a main box part, and a planetary gear train mechanism and a widened twin cone lock ring synchronizer are arranged in the sub-box part. The gearbox has the advantages that the operation is labor-saving, the gear shifting operation and the transmission are smooth, the noise is small, and the physical life is prolonged.

Owner:SINO TRUK JINAN POWER

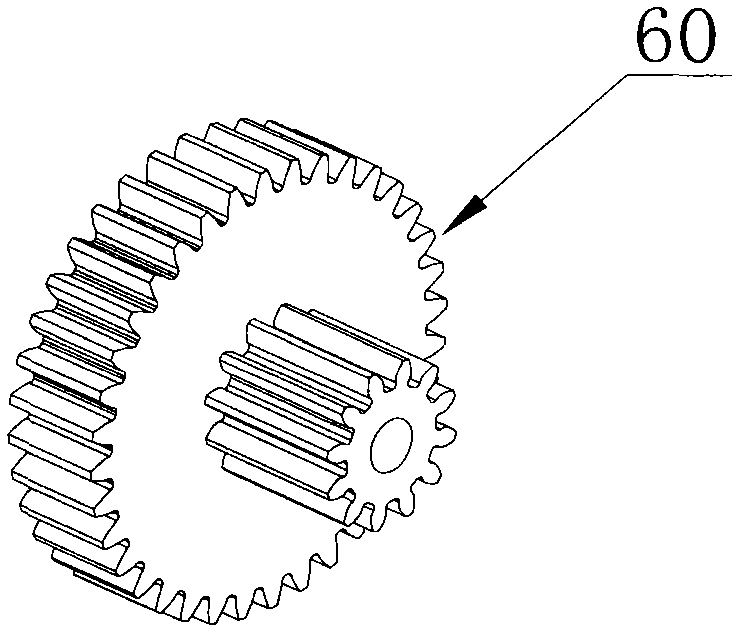

Gear

InactiveCN110131381AEasy to installImprove wear resistancePortable liftingGearing elementsWear resistantInvolute gear

The invention belongs to the technical field of gears, and particularly relates to a gear. The gear comprises a gear body, wherein teeth are uniformly arranged on the gear body, sliding cavities are uniformly formed in the gear body, a partition baffle is arranged in each sliding cavity, sliding grooves are formed in the teeth, friction blocks are arranged in one sides of the sliding grooves, magnet layers are arranged at the bottom ends of the friction blocks, arc-shaped wear-resistant layers are arranged on the outer side surfaces of the friction blocks, the friction blocks are inserted intothe sliding cavities, the width of the bottom end of each friction block is equal to the distance between the corresponding partition baffle and the side wall of the corresponding sliding cavity, andthe other side surfaces of the partition baffles are in contact with standby blocks. According to the gear, the friction blocks and the standby blocks are arranged, the friction blocks and the standby blocks are correspondingly arranged in the sliding cavities, then the arranged friction blocks and the arranged standby blocks can be used for improving the wear resistance of the teeth, then the degree of abrasion between the teeth on the mutually meshed gears is reduced, and then the bending strength of the teeth on the involute gear and the meshing stability between the teeth are improved.

Owner:薛江波

Thorn wrench for preventing tooth breakup

ActiveCN101774163AAvoid chippingAvoid the disadvantages of chippingSpannersWrenchesStress concentrationBreakup

The invention relates to a thorn wrench for preventing tooth breakup. A connecting part of a control member is provided with at least two elasticity positioning assemblies; at least two positioning units support against an abutting part of a thorn member simultaneously so that a ratchet of the thorn member can be engaged on a driving tooth of a driven body at high speed to avoid tooth breakup caused by stress concentration; at least two elasticity positioning assemblies arranged on the control member support against the thorn member, thereby overcoming oil stain prevention between the thorn member and the driven body and solving the tolerance problem of poor parallelism or verticality among a holding hole, a control slot and a thorn slot inside the body so that the upper part and the lower part of the thorn member are simultaneously engaged in the driven body, the function of high-speed engagement is achieved, the engagement stability is improved, and tooth breakup is reduced.

Owner:胡厚飞

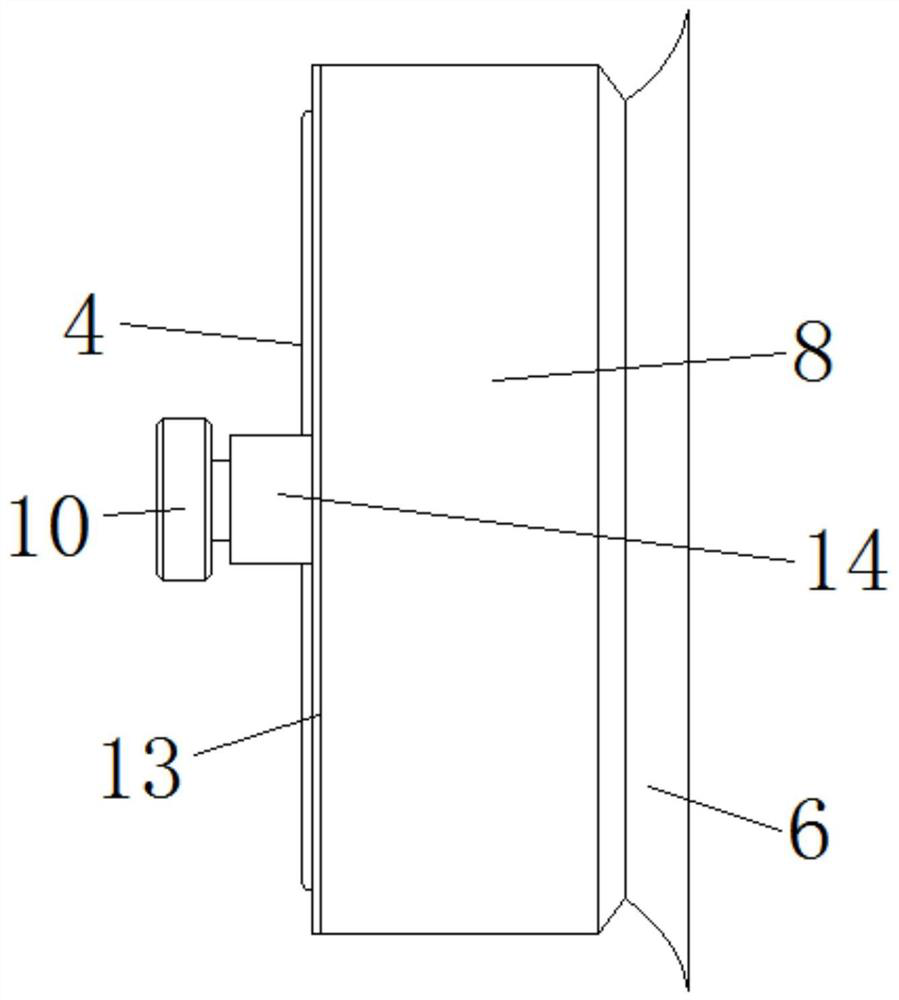

LED display suite

The invention relates to the technical field of LED display, and provides an LED display suite which is convenient to disassemble, and capable of reducing costs and labor intensity of installation maintenance personnel. The LED display suite includes a base shell, an LED face cover with LED lamp mounting holes formed uniformly in the surface of the base shell, and a fixing frame for fixing and installing the base shell, a locking shaft is arranged on the base shell, a locking shaft hole for embedding the locking shaft is formed in the fixing frame, a locking part is arranged also on the fixingframe, the locking part comprises a threaded shaft, a transferring head and a rotating head, the expansion of the threaded shaft in the axial direction of the locking shaft hole is achieved through the rotating drive of the transferring head and the rotating head, and the detachable wear of the locking shaft by the threaded shaft is achieved.

Owner:安徽锐新新能源科技有限公司

Thorn wrench for preventing tooth breakup

ActiveCN101774163BAvoid chippingAvoid the disadvantages of chippingSpannersWrenchesStress concentrationBreakup

The invention relates to a thorn wrench for preventing tooth breakup. A connecting part of a control member is provided with at least two elasticity positioning assemblies; at least two positioning units support against an abutting part of a thorn member simultaneously so that a ratchet of the thorn member can be engaged on a driving tooth of a driven body at high speed to avoid tooth breakup caused by stress concentration; at least two elasticity positioning assemblies arranged on the control member support against the thorn member, thereby overcoming oil stain prevention between the thorn member and the driven body and solving the tolerance problem of poor parallelism or verticality among a holding hole, a control slot and a thorn slot inside the body so that the upper part and the lower part of the thorn member are simultaneously engaged in the driven body, the function of high-speed engagement is achieved, the engagement stability is improved, and tooth breakup is reduced.

Owner:胡厚飞

Novel lock ring synchronizer gearbox with ten-gear dual-intermediate shaft

InactiveCN103363041AReduce noiseImprove carrying capacityToothed gearingsGearing detailsEngineeringGear train

The invention discloses a novel lock ring synchronizer gearbox with a ten-gear dual-intermediate shaft. The novel lock ring synchronizer gearbox comprises a novel three-section case. The dual-intermediate shaft comprises an input shaft and a main shaft, the input shaft is arranged in a main box and is connected with the main shaft, the main shaft is connected with a sun wheel through a spline transition sleeve, the sun wheel is arranged in a sub box, a main shaft front locating mechanism and a main shaft back locating mechanism are respectively arranged at the front end and the back end of the main shaft, a gear shift helical gear set is further arranged on the main shaft, the gear shift helical gear set comprises five forward gear helical gears and a reverse gear helical gear, a pyramid lock ring synchronizer is arranged between the fourth gear and the fifth gear of the main shaft, bipyramid lock ring synchronizers are arranged between the second gear and the third gear and on a first reverse gear respectively, two gears are arranged on the sub box, the two gears arranged on the sub box and the main box form a structure of 5*2 10 forward gears and two reverse gears, and a planetary gear train mechanism and a widened bipyramid lock ring synchronizer are arranged in the sub box. The gearbox is saving in operation labor, stable in gear shift operation, smooth and steady in transmission, low in noise and long in service life.

Owner:SINO TRUK JINAN POWER

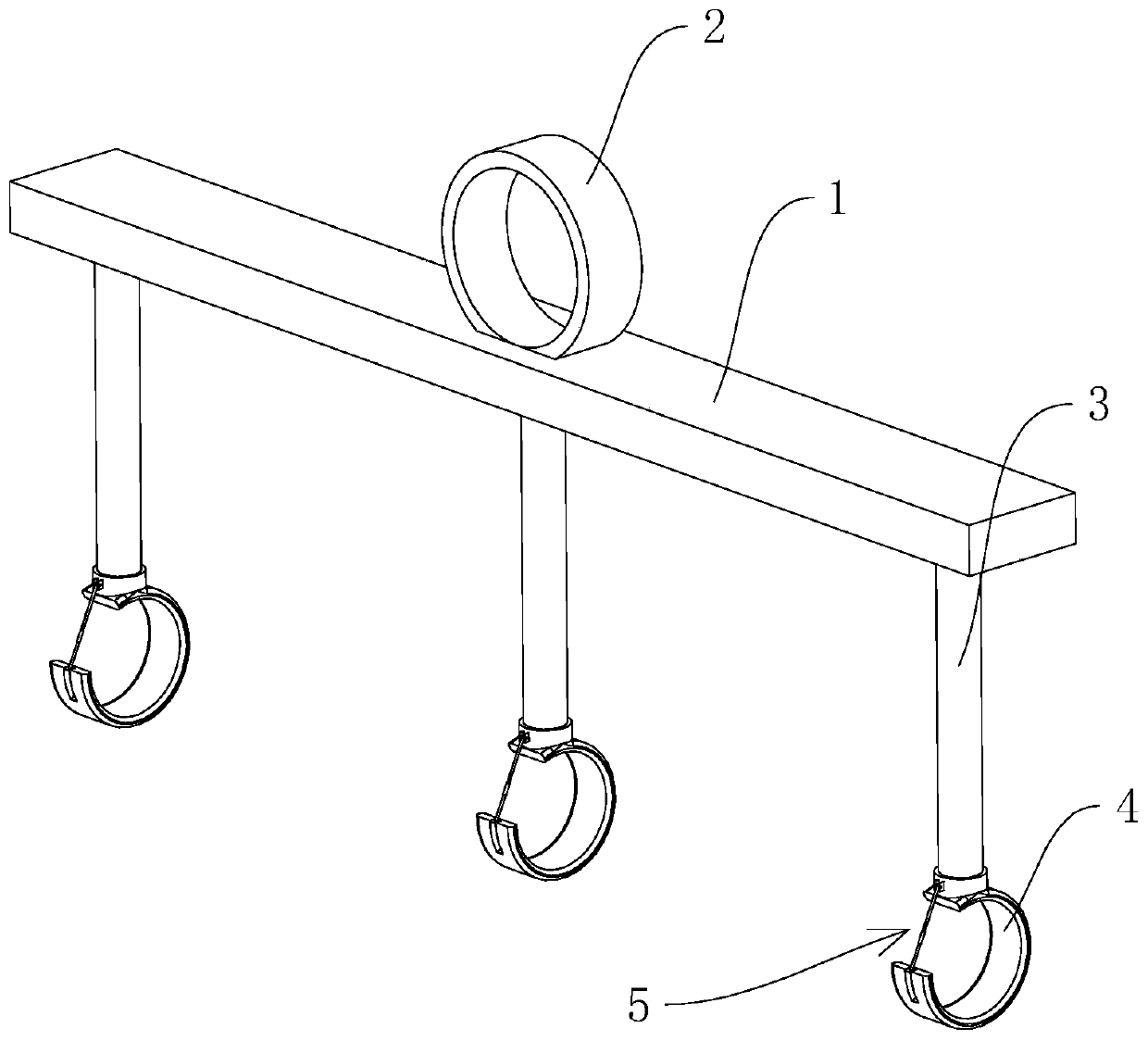

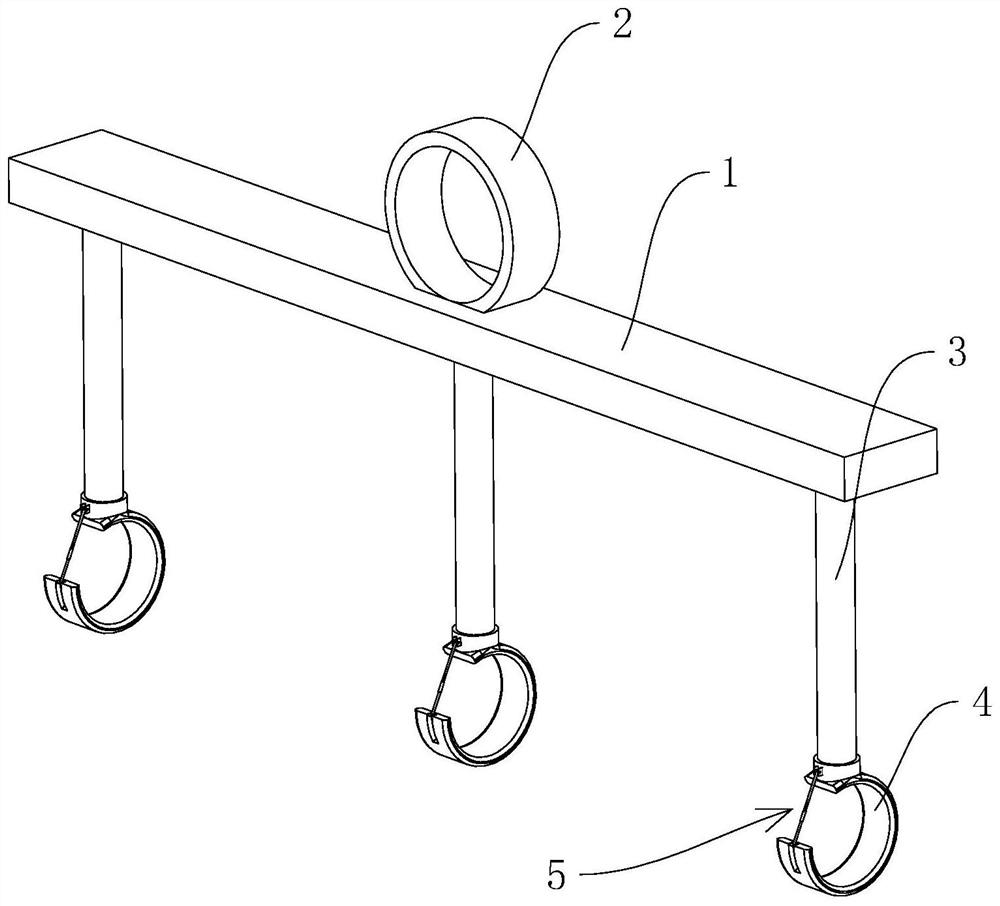

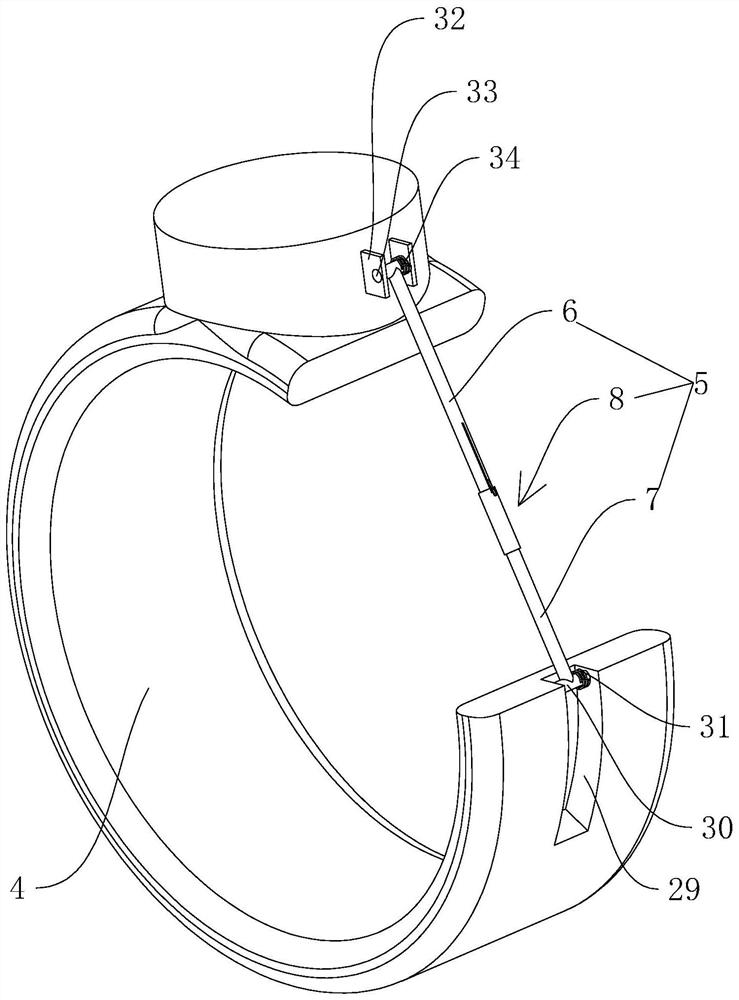

Hoisting device for assembled prefabricated wall

The invention relates to a hoisting device for an assembled prefabricated wall. The hoisting device comprises a bracket, wherein the upper surface of the bracket is fixedly connected with a hand ring;the lower surface of the bracket is fixedly connected with three groups of connecting steel ropes; one end of each connecting steel rope is fixedly connected with a lifting hook; three groups of connecting steel ropes are evenly arranged at intervals; each lifting hook is provided with a sealing mechanism used for conveniently sealing each lifting hook; when the prefabricated wall is hoisted, thelifting hooks are hooked on the pre-embedding elements of the prefabricated wall, and the lifting hooks are sealed through the sealing mechanisms; and a jack-up mechanism hoists the bracket through the lifting hooks. Due to the arrangement, the hoisting device has a simple structure and is convenient to operate, stability for hooking the lifting hooks to the pre-embedding elements of the prefabricated wall is improved, and prefabricated wall hoisting safety is improved.

Owner:南通市建筑设计研究院有限公司

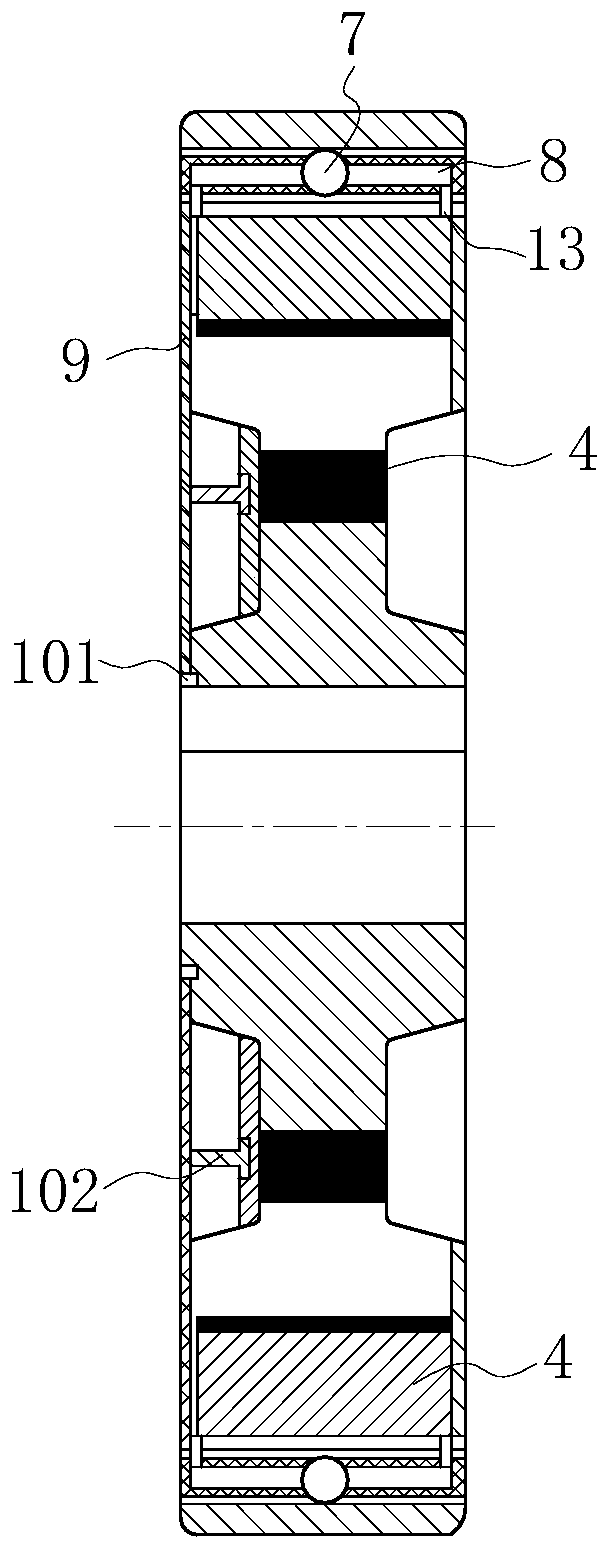

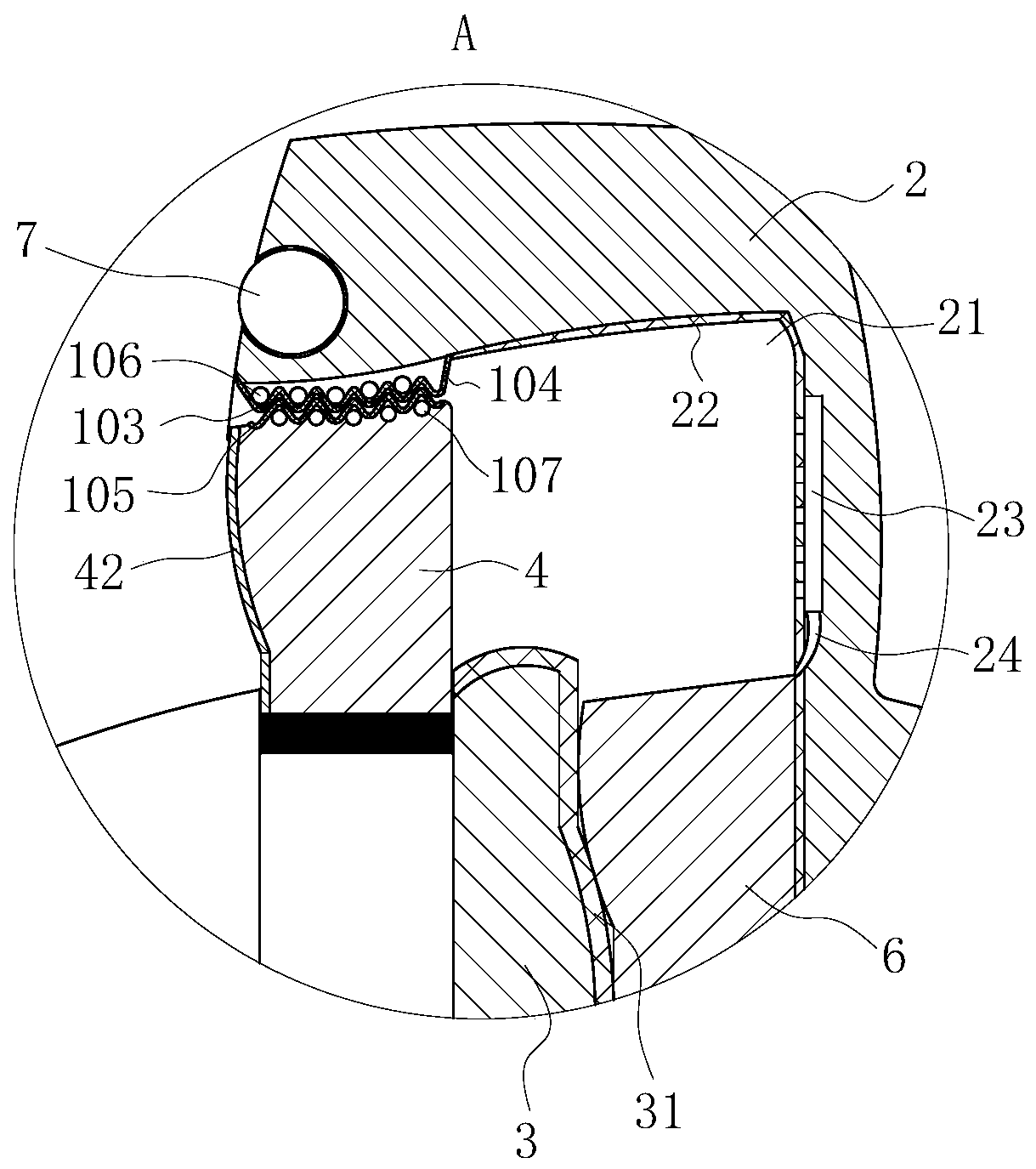

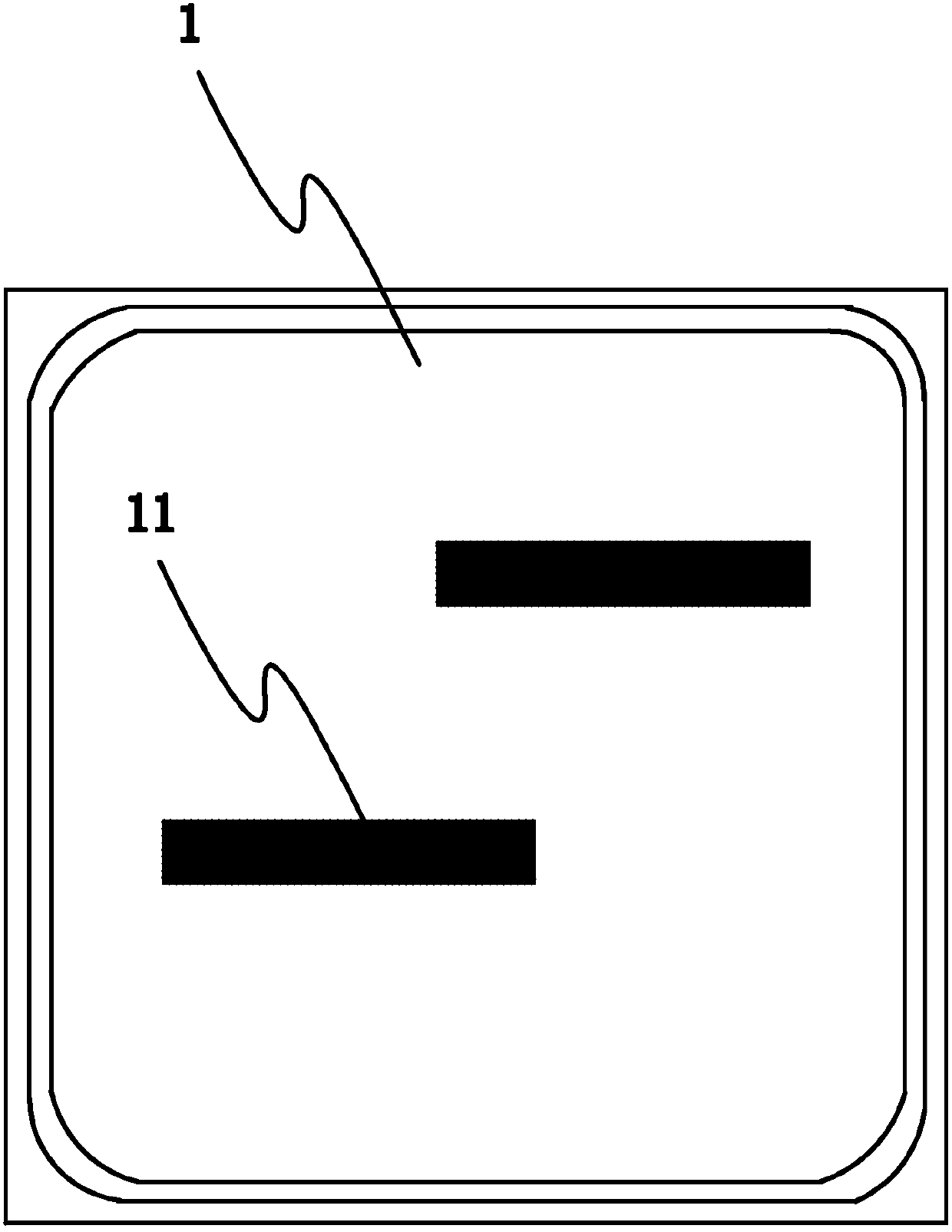

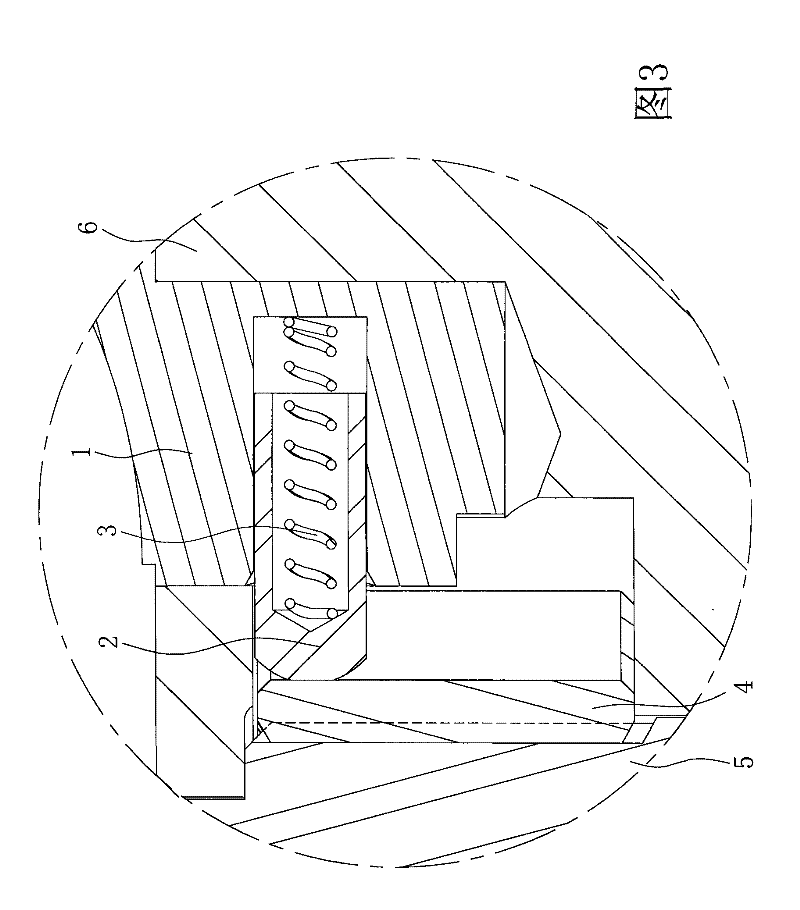

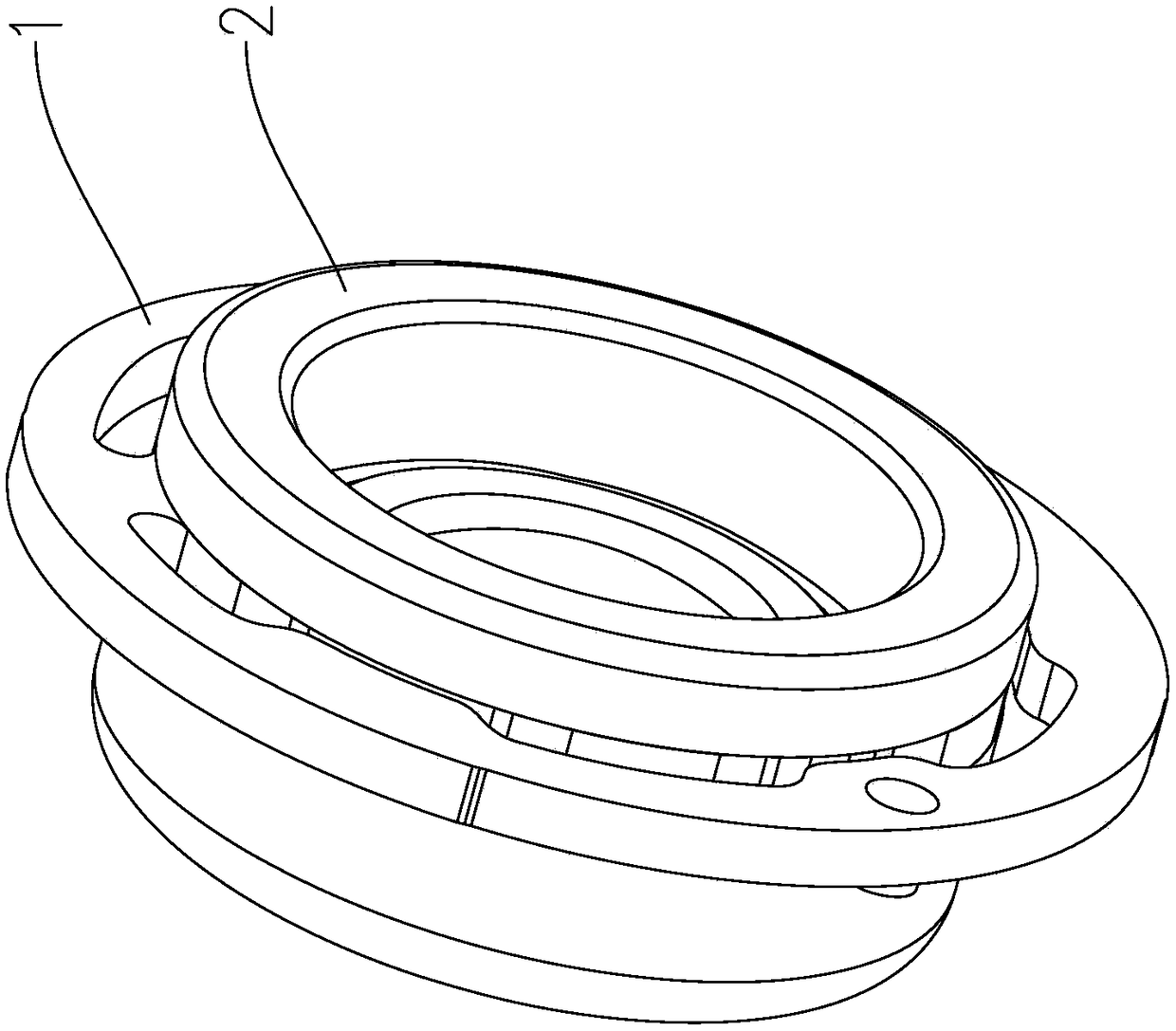

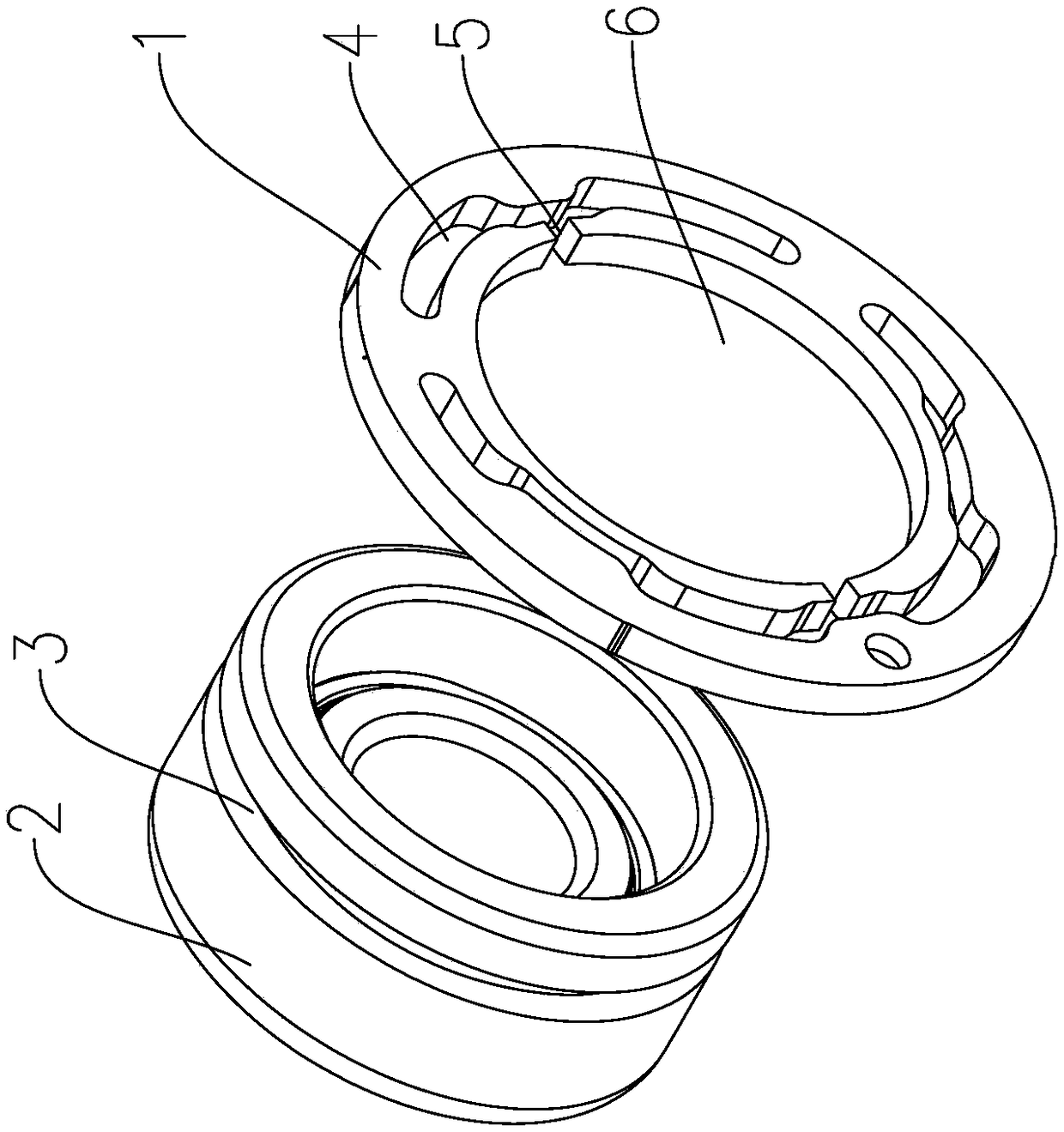

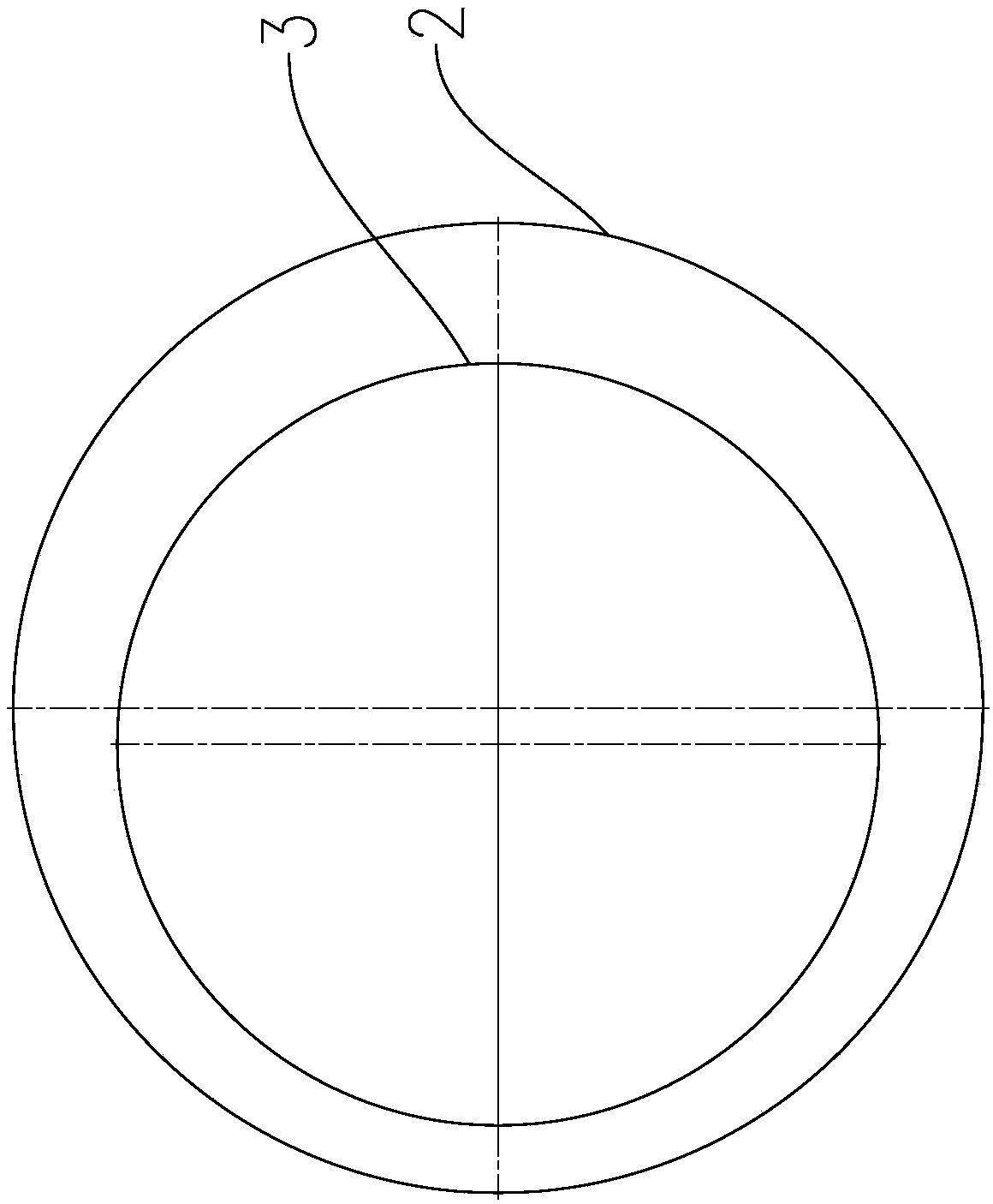

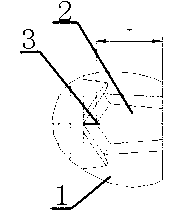

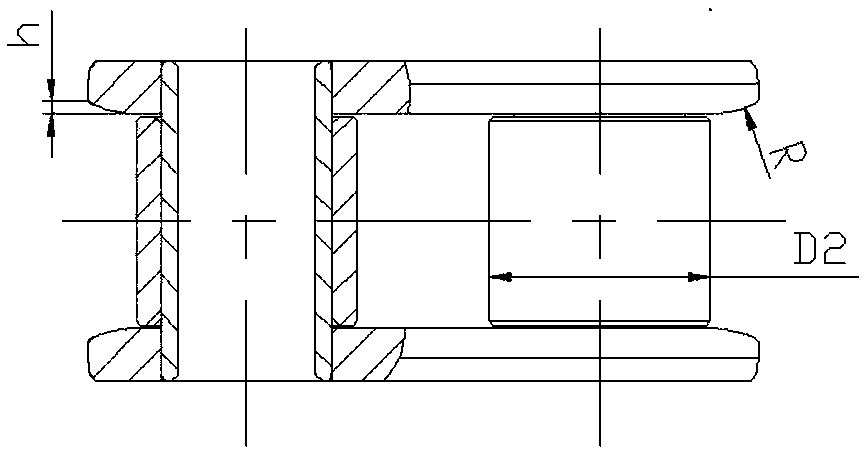

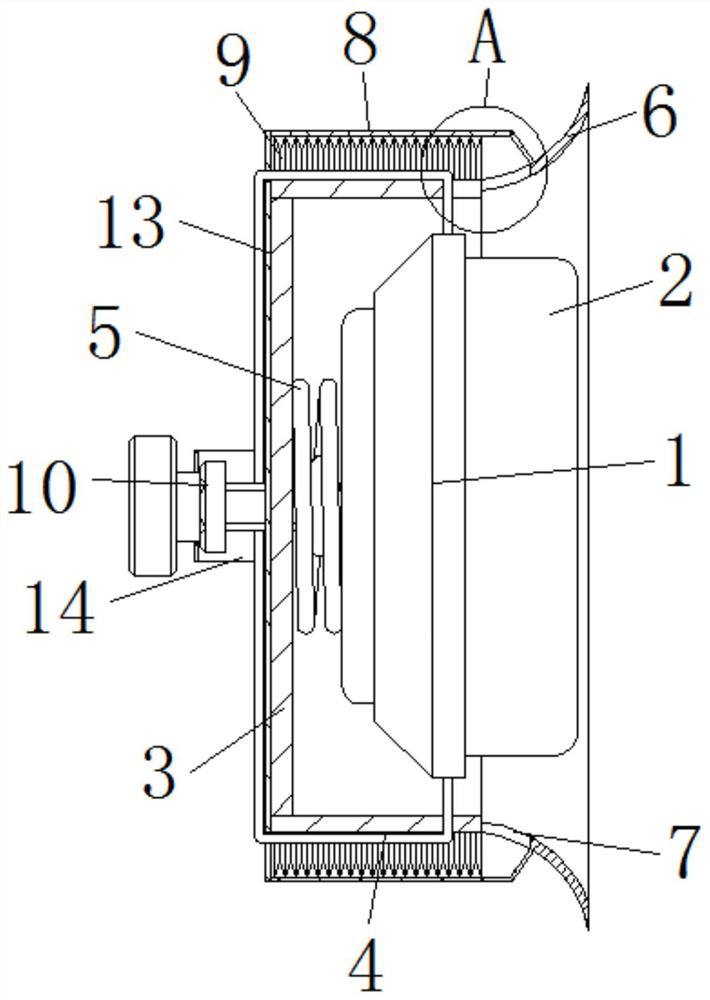

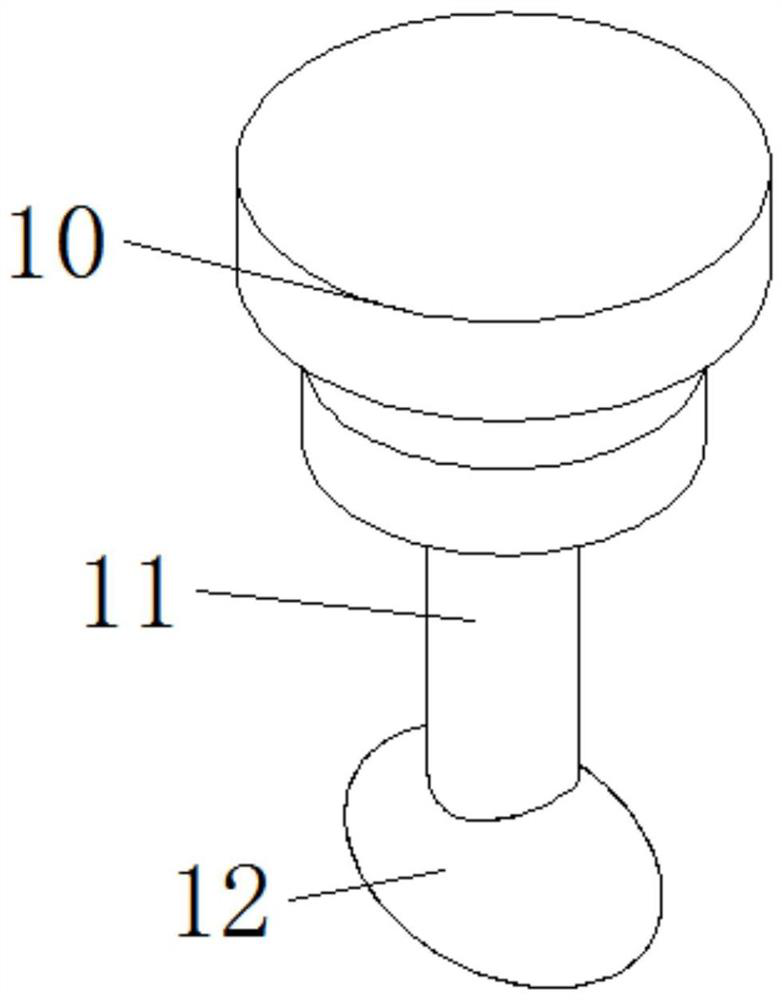

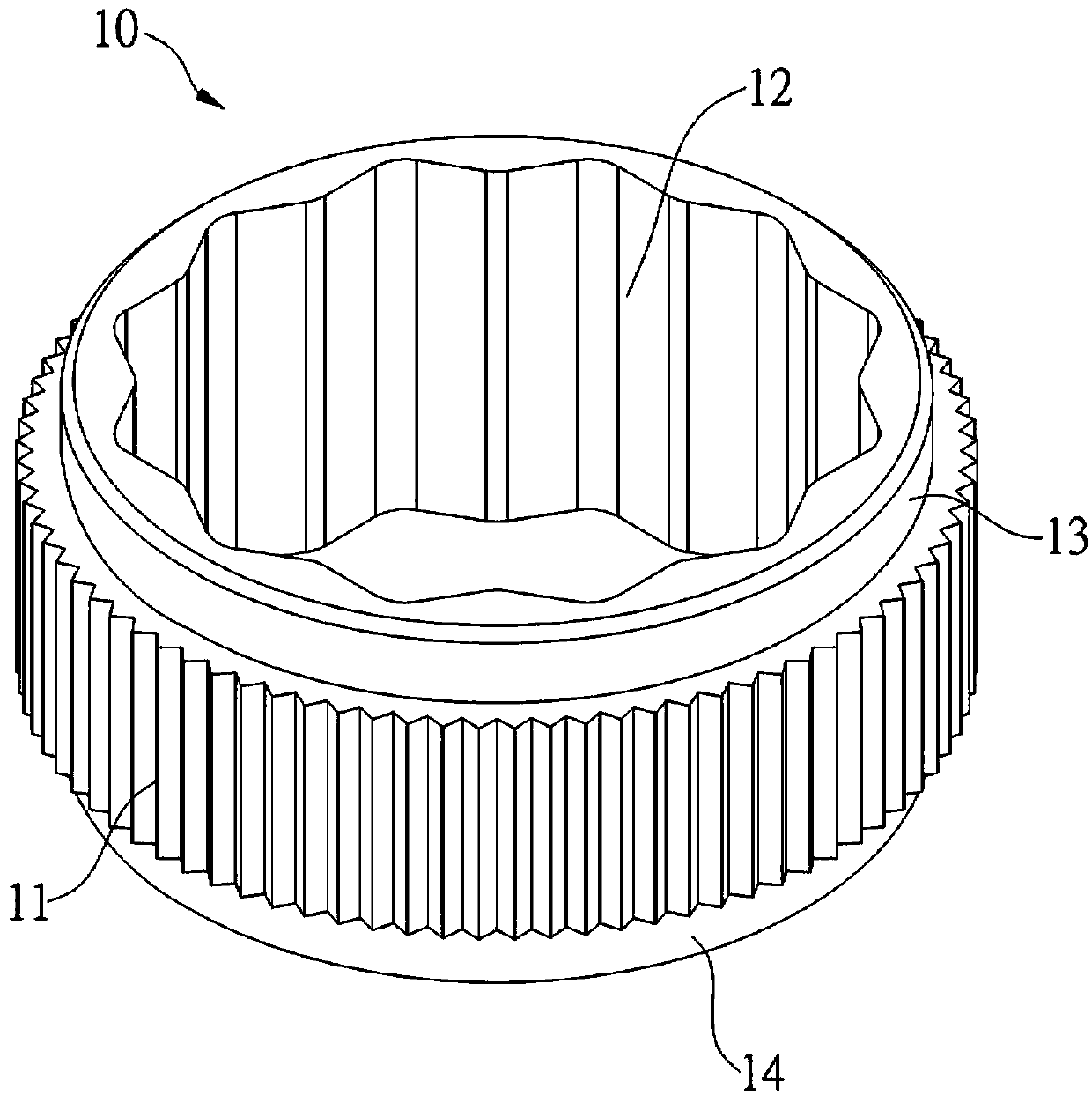

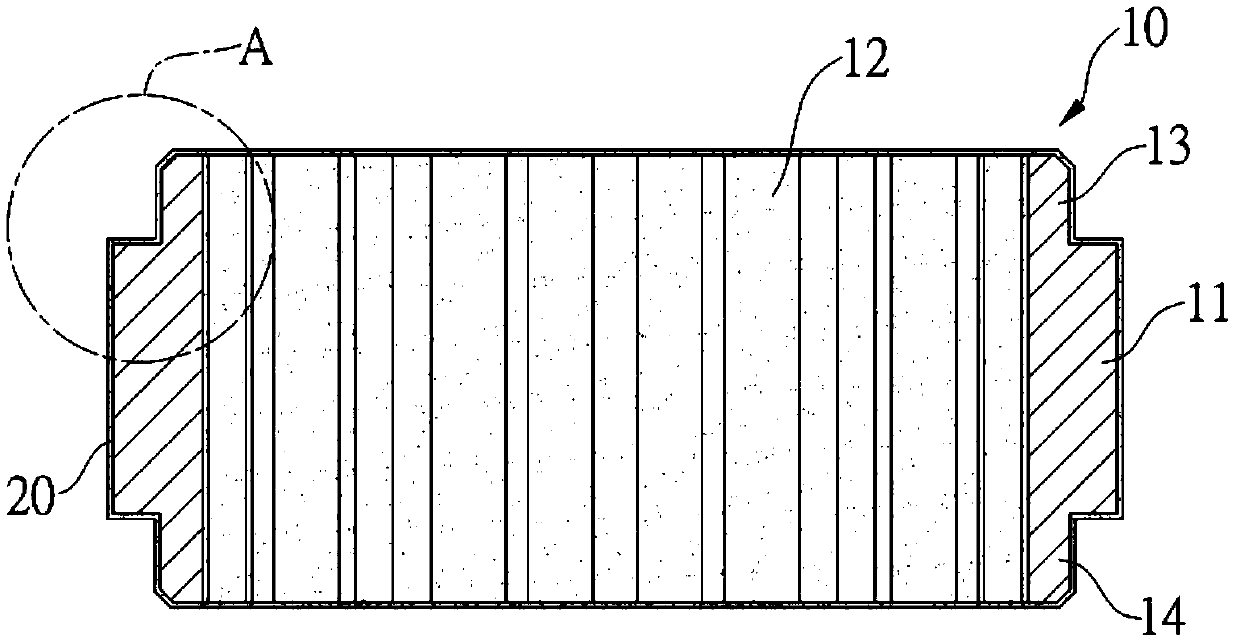

Elastic supporting bearing structure

PendingCN108189905AImprove mesh stabilityPrevent savingNon-rotating vibration suppressionMechanical steering gearsElectric power steeringBall bearing

The invention relates to a bearing structure, particularly to an elastic supporting bearing structure, and belongs to the technical field of the bearing structure. The elastic supporting bearing structure comprises a floating elastic block and a ball bearing; a locking slot is arranged on the surface of an outer circumference of the ball bearing, the floating elastic block is embedded in the locking slot of the ball bearing; an installing cavity is arranged in the center of the floating elastic block, and at least one elastic slot is arranged on the floating elastic block; a pressing slot is arranged between the installing cavity and the elastic slot, the pressing slot is connected with the installing cavity and the elastic slot. The elastic supporting bearing structure is simple, compactand reasonable in structure, low in manufacturing cost, and high in product stability; the transferred vibration can be completely absorbed by using the floating elastic block, the worm movement in crowd is prevented, the noise happening is reduced, the meshing stability of an electric power steering machine of an automobile is improved, and the service life is prolonged.

Owner:WUXING HUAYANG ROLLING BEARING JIANGSU LITTLESWAN GROUP

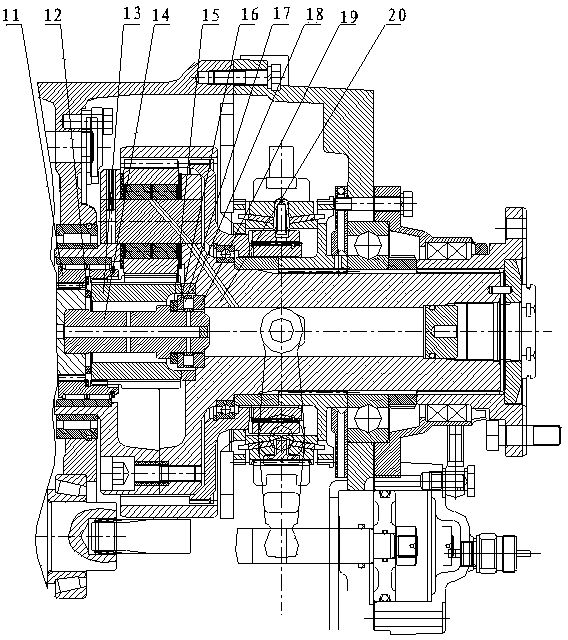

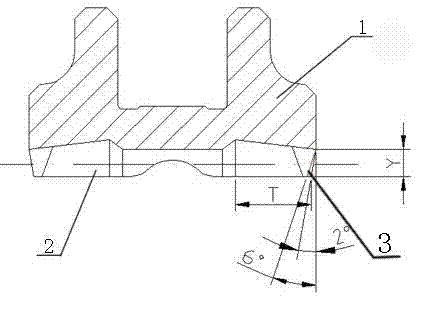

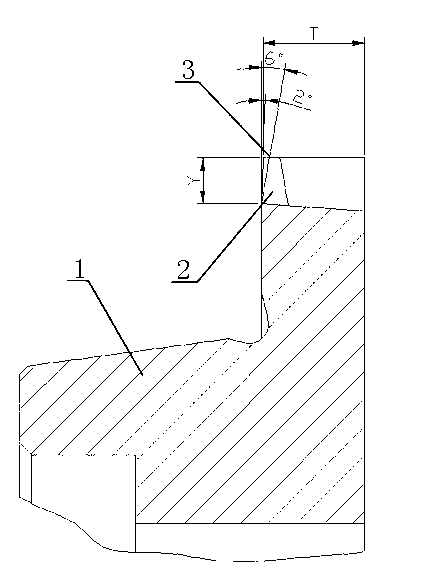

Toothed sleeve of synchronizer for passenger car

InactiveCN102829097AImprove mesh stabilityGuaranteed reliabilityMechanical actuated clutchesEngineeringFerrule

The invention relates to a toothed sleeve of synchronizer for a passenger car. The toothed sleeve comprises a ferrule, and a plurality of internal teeth which are arranged along the axial direction of the ferrule and evenly distributed on the inner circumferential wall of the ferrule, wherein the outer end surfaces on the two ends of the internal teeth are in cutting edge shapes; cutting edge inclinations at cutting edges on the outer end surfaces on the two sides of the internal teeth are 1-5 DEG; the thicknesses and the widths of the middle parts of the internal teeth are the same; and the widths of the two side parts of the internal teeth are gradually increased from inside to outside and the thicknesses of the two side parts of the internal teeth are gradually decreased from inside to outside. The outer end surfaces on the two sides of the internal teeth are in the cutting edge shapes, and the cutting edges on the outer end surfaces on the two sides of the internal teeth are positioned at ferrule locking corners and the cutting edge inclinations are 1-5 DEG; and compared with traditional cutting edge inclinations greater than 6 DEG, the cutting edge inclinations of 1-5 DEG has the longer meshing length with connecting teeth, so the meshing stability, the firmness and the use safety are beneficially improved and the reliability of gear shifting of a speed changing box is guaranteed.

Owner:唐海滨

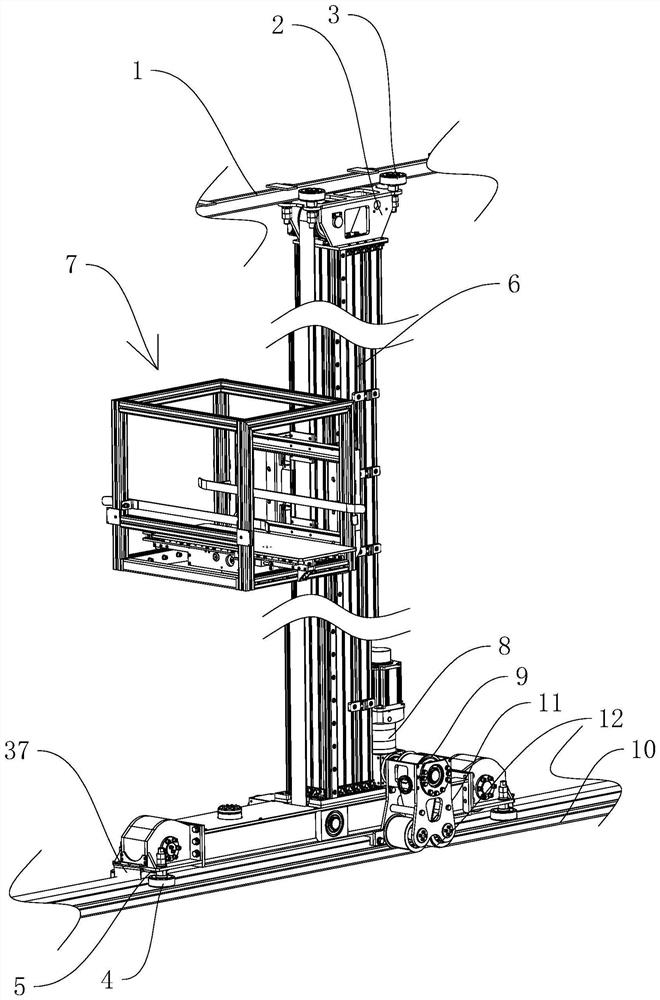

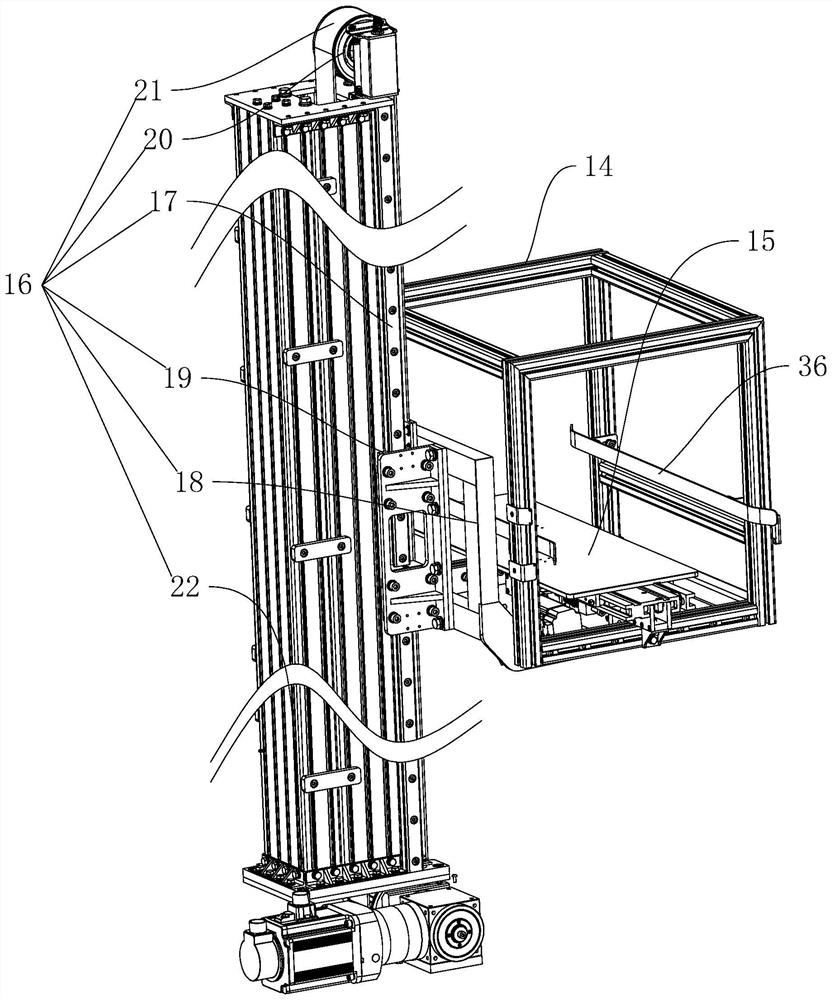

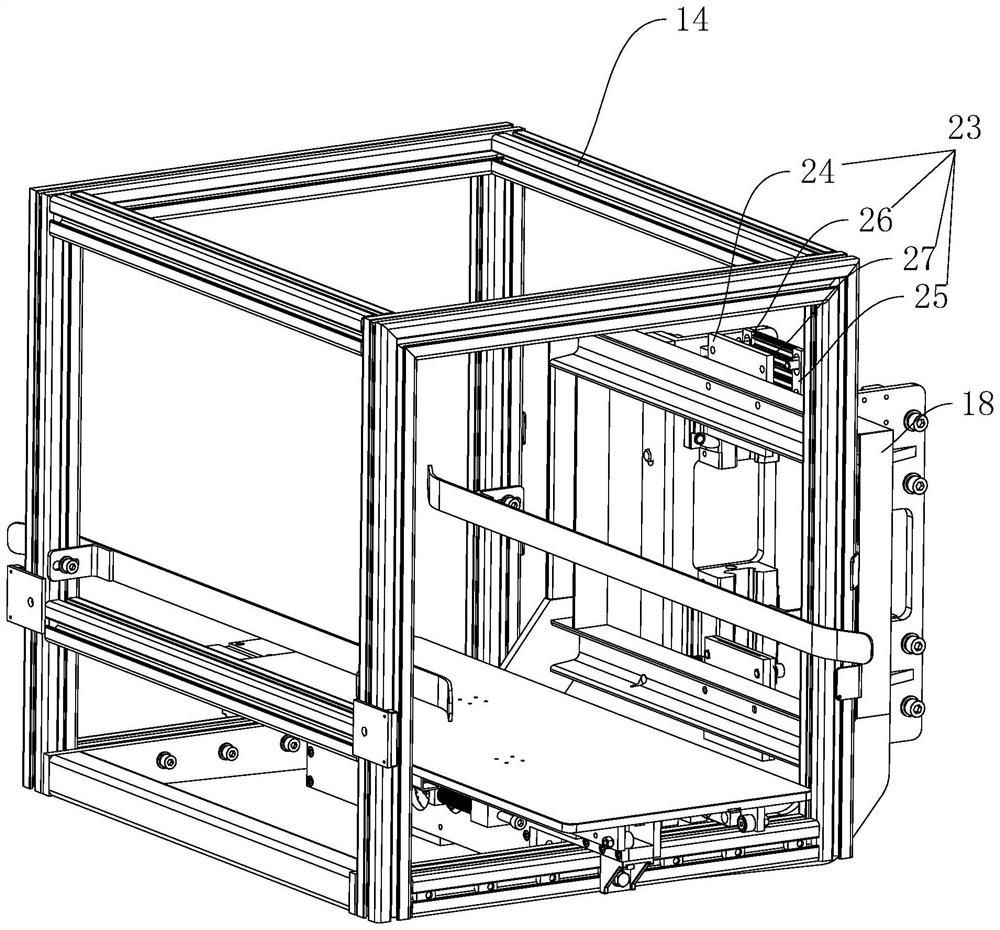

Stacking machine

PendingCN114684748AImprove swipe accuracySimple structureLifting devicesElectric machineryEngineering

The invention provides a stacking machine convenient to use, and belongs to the technical field of stacking equipment, the stacking machine comprises two sliding rails arranged up and down, a stacking machine body arranged between the two sliding rails, a first motor fixedly connected to the stacking machine body, a first synchronous wheel fixedly connected to an output shaft of the first motor, and a second synchronous wheel fixedly connected to an output shaft of the second motor. A first synchronous belt is fixedly connected to the ground, teeth of the first synchronous belt face the ground, the first synchronous belt is meshed with the first synchronous wheel, the first synchronous wheel is located below the first synchronous belt, and an abutting mechanism used for enabling the first synchronous belt to be meshed with the first synchronous wheel all the time is arranged on the stacking machine body. The support has the advantage that the sliding accuracy of the support on the sliding rail is improved.

Owner:平湖市开浦机电集成有限公司

Environment-friendly plate crushing and sampling device

PendingCN112916117AImprove rotational stabilityImprove crushing efficiencyGrain treatmentsGear wheelEngineering

The invention discloses an environment-friendly plate crushing and sampling device which comprises a base, the base is mounted on a bottom plate, a positioning mechanism is arranged on the base and comprises positioning frames and positioning seats, the positioning frames are mounted on two sides of the middle of the base, and the positioning seats are mounted on two sides of the front end of the base. A driving roller is arranged between the tops of the positioning frames, a driving crushing gear is arranged at the front end of the driving roller, a driven roller is arranged at the top of the positioning seat, a driven crushing gear is arranged at the front end of the driven roller, crushing teeth are arranged on the peripheral surfaces of the driven crushing gear and the driving crushing gear, and a crushing cavity is formed between the driven crushing gear and the driving crushing gear. The environment-friendly printing resin plate material is crushed through the driving crushing gear and the driven crushing gear, so that the crushing efficiency of the environment-friendly printing resin plate material is greatly improved, and the meshing stability of a transmission gear and the driving crushing gear and the meshing stability of the transmission gear and the driven crushing gear are improved.

Owner:倪沈华

A device for automatic detection of runout of bevel gears in automobiles

ActiveCN110375607BSolve the problem that detection is susceptible to light interferenceHighly creativeMechanical measuring arrangementsGear wheelMechanical drive

The invention relates to an automobile bevel gear automatic detecting and bouncing device. The device comprises a pedestal, a shaft support, a curved rod support and a gear support, wherein the shaftsupport, the curved rod support and the gear support are successively and fixedly arranged on the pedestal. An eccentric wheel is rotatably installed in the shaft support. A curved rod is rotatably installed on a top of the curved rod support, one end of the curved rod is slidably cooperated with an outer circumference of the eccentric wheel, and the other end of the curved rod is fixedly providedwith a detecting rod. One side of the shaft support is connected with a power unit providing rotational power to the eccentric wheel, and the other side of the shaft support is connected with a transmission unit providing rotational power for a gear to be detected on the gear support. A dial indicator for detecting a swinging limit of the curved rod and a reset spring for providing reset supportfor the curved rod are installed on the pedestal. The detecting device solves a problem that precision of manual detection of a gear tooth type is not high in the prior art, and realizes full mechanical transmission and automatic detection of full mechanical calibration at the same time. The device has advantages of low cost, a high detection speed, high detection precision and the like.

Owner:TIANJIN ZENGYIDA PRECISION FORGING GEAR TECH CO LTD

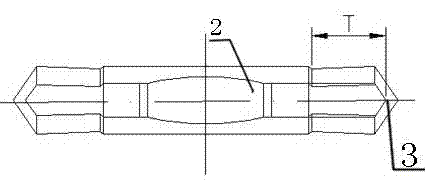

Synchronizer jointing tooth for car

InactiveCN102840248AGuaranteed reliabilityImprove mesh stabilityMechanical actuated clutchesOrthodonticsFerrule

The invention relates to a synchronizer jointing tooth for a car. The synchronizer jointing tooth comprises a sleeve ring, and a plurality of external teeth axially uniformly distributed on the peripheral wall of the sleeve ring along the sleeve ring, wherein the external end face of one side of each external tooth is in a shape of cutting edge; and an edge at the cutting edge on the external end face of one side of each external tooth has the inclination angle of 1 to 5 degrees. According to the synchronizer jointing tooth for the car, the external end face of one side of each external tooth is in a shape of cutting edge, the cutting edge on the external end face of one side of an internal tooth is a tooth sleeve locking angle, the edge has the inclination angle of 1 to 5 degrees; and compared with the traditional edge inclination angle of 6 degrees, the edge provided by the invention has the advantages that the engaging length of the internal tooth of the tooth sleeve is increased, so that the stability and firmness in engaging and the safety in use can be improved; and the reliability of a gearbox in shifting is ensured.

Owner:唐海滨

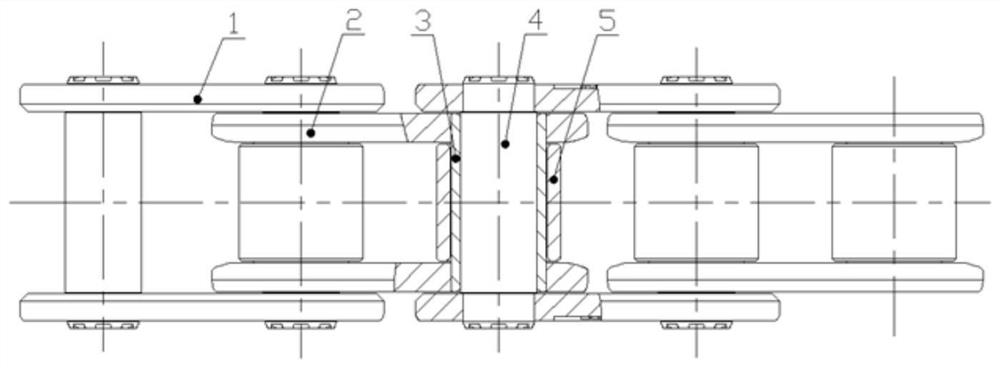

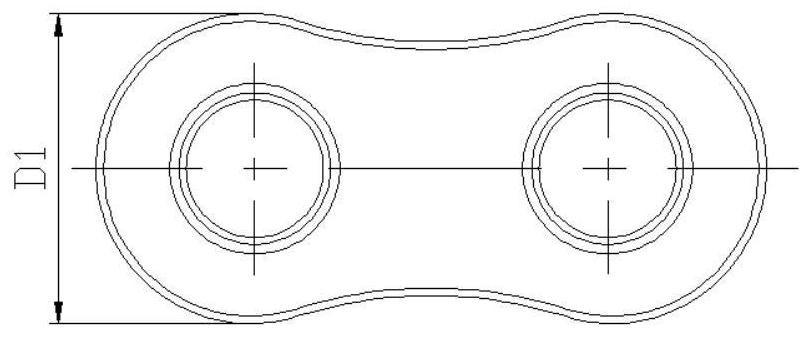

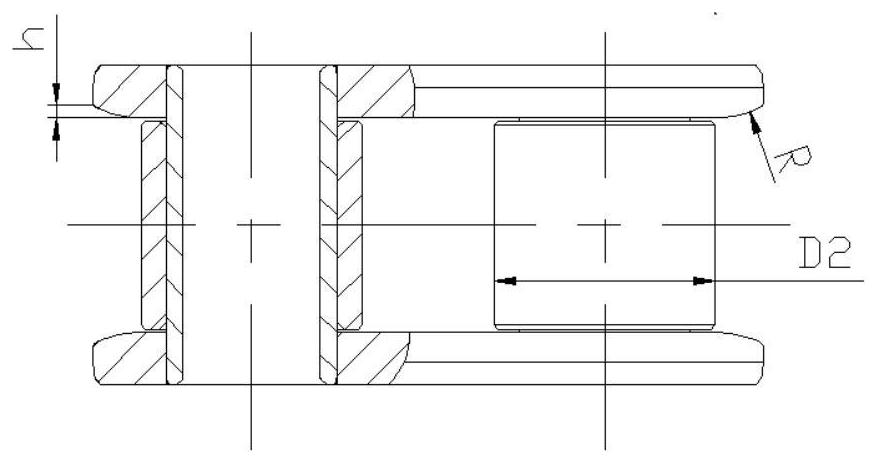

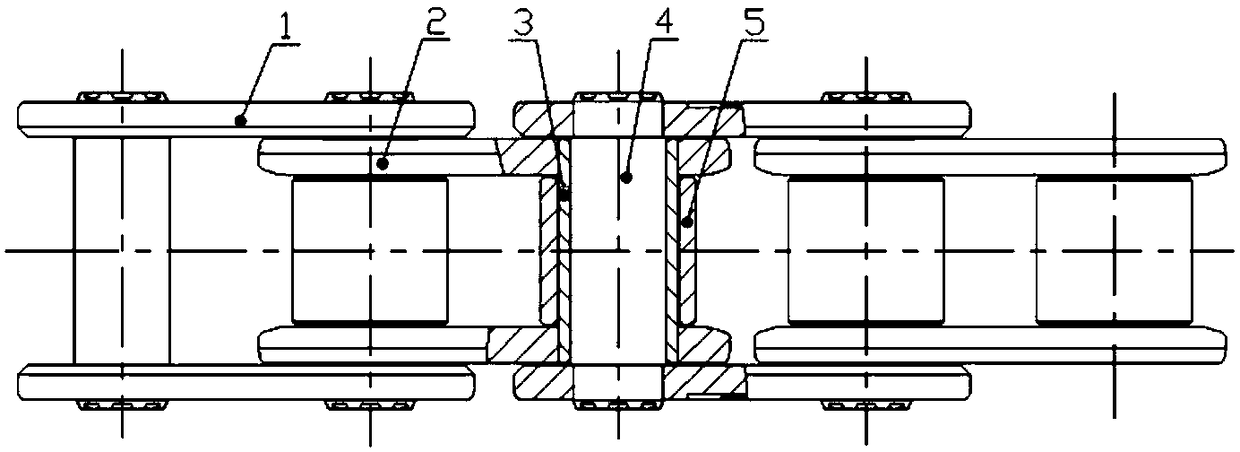

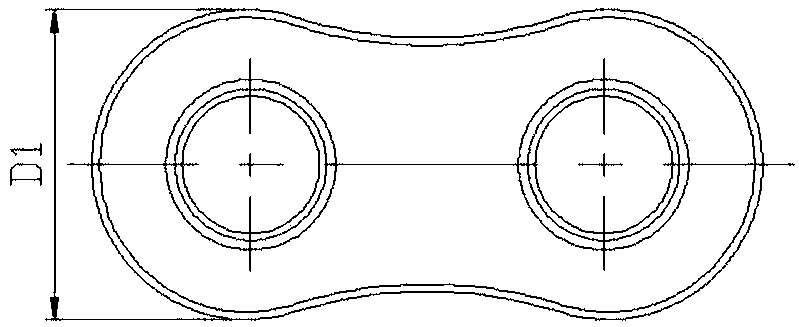

A low-speed high-power marine engine timing chain

ActiveCN109027130BEvenly distributedGuaranteed pressureChain linksDriving chainsInterference fitChain length

The invention relates to a low-speed high-power marine engine timing chain which comprises inner chain links and outer chain links. Each inner chain link is formed in the manner that inner link platesand sleeves are in interference fit and the sleeves and rollers are in clearance fit, each outer chain link is formed in the manner that outer chain plates and pin shafts are in interference fit, andthe inner chain links and the outer chain links are staggered and embedded with each other to form the whole chain through clearance fit of the pin shafts and the sleeves. In each inner chain link, one side of each chain plate is provided with an engaged circular bead, and wear and impact generated by the chain and a sprocket can be avoided; and each sleeve is designed to be of a tapered structure and adopts a honing process after assembling, and therefore the effect of radial shrinking generated by interference fit on the wear resistance of the chain is avoided. The chain adopts an octagonalriveting method, the chain length is detected on the basis of 10-20 links in the initial stage of chain assembly, whole chain connection is carried out in the manner that the chain lengths of reference chain segments are gradually increased from the two sides to the middle, and the using performance of the large-size chain at low-speed heavy-loaded conditions is improved.

Owner:QINGDAO CHOHO IND CO LTD

Low-speed high-power marine engine timing chain

ActiveCN109027130AAvoid Mutual WearEvenly distributedChain linksDriving chainsInterference fitLow speed

The invention relates to a low-speed high-power marine engine timing chain which comprises inner chain links and outer chain links. Each inner chain link is formed in the manner that inner link platesand sleeves are in interference fit and the sleeves and rollers are in clearance fit, each outer chain link is formed in the manner that outer chain plates and pin shafts are in interference fit, andthe inner chain links and the outer chain links are staggered and embedded with each other to form the whole chain through clearance fit of the pin shafts and the sleeves. In each inner chain link, one side of each chain plate is provided with an engaged circular bead, and wear and impact generated by the chain and a sprocket can be avoided; and each sleeve is designed to be of a tapered structure and adopts a honing process after assembling, and therefore the effect of radial shrinking generated by interference fit on the wear resistance of the chain is avoided. The chain adopts an octagonalriveting method, the chain length is detected on the basis of 10-20 links in the initial stage of chain assembly, whole chain connection is carried out in the manner that the chain lengths of reference chain segments are gradually increased from the two sides to the middle, and the using performance of the large-size chain at low-speed heavy-loaded conditions is improved.

Owner:QINGDAO CHOHO IND CO LTD

A hoisting device for an assembled prefabricated wall

ActiveCN111498676BEasy hook upSimple structureLoad-engaging elementsClassical mechanicsStructural engineering

The invention relates to a hoisting device for an assembled prefabricated wall, which includes a bracket, a suspension ring is fixedly connected to the upper surface of the bracket, three sets of connecting steel ropes are fixedly connected to the lower surface of the bracket, and one end of the connecting steel rope A hook is fixedly connected, and the three sets of connecting steel ropes are evenly spaced. A closing mechanism is provided on the hook to facilitate closing the hook. When the prefabricated wall is hoisted, the hook The hook is set on the embedded part of the prefabricated wall, the hook is closed by the closing mechanism, and the lifting mechanism lifts the bracket through the ring. Through this setting, the structure is simple, the operation is convenient, and the hook is hooked on the prefabricated wall. The stability on the embedded parts improves the safety of prefabricated wall hoisting.

Owner:南通市建筑设计研究院有限公司

Braking structure for water conservancy and hydropower equipment and braking method

InactiveCN113417952AImprove stabilityFunction increaseBraking membersHydraulic engineering apparatusDrive shaftControl engineering

The invention discloses a brake structure for water conservancy and hydropower equipment. The braking structure for the water conservancy and hydropower equipment comprises a support and a transmission shaft body located at the top of the support, transmission rods are movably connected to the left side and the right side of the front face of the support through hinge pins, a braking frame is installed on the inner sides of the transmission rods through a fixed structure, the braking frame is located on the two sides of the transmission shaft body, a sleeve plate is slidably connected to the inner side of the support, an extrusion block is fixedly connected to the top of the sleeve plate, a supporting wheel is fixedly connected to the top of the extrusion block, and the outer surface of the supporting wheel makes contact with the surface of the transmission shaft body. According to the braking structure for the water conservancy and hydropower equipment, supporting is carried out on the braking frame through supporting wheels, the braking stability is further improved, a braking device has the supporting and positioning effects in the non-working process, the function of the braking structure is increased, and the problems that an existing braking structure is single in structure and function, the effect that supporting is carried out on the transmission shaft is not achieved in the non-braking process, and application range of braking structure is seriously affected are solved.

Owner:湖北万城节能有限公司

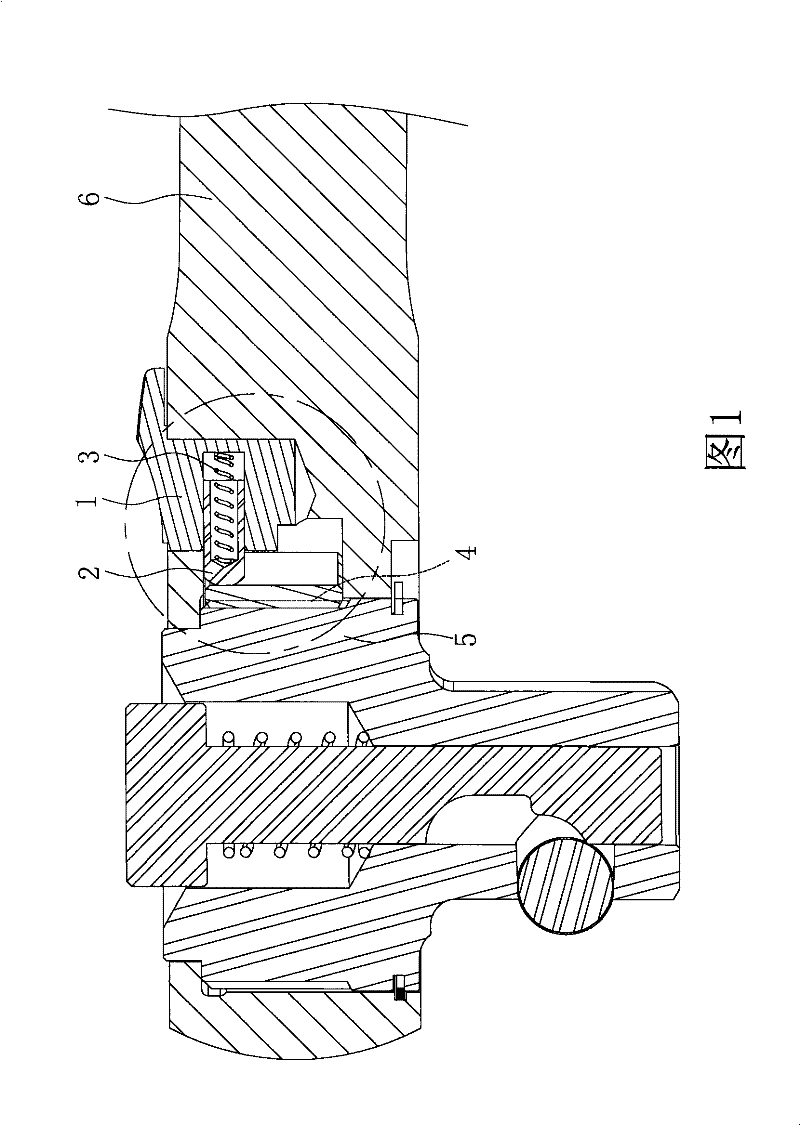

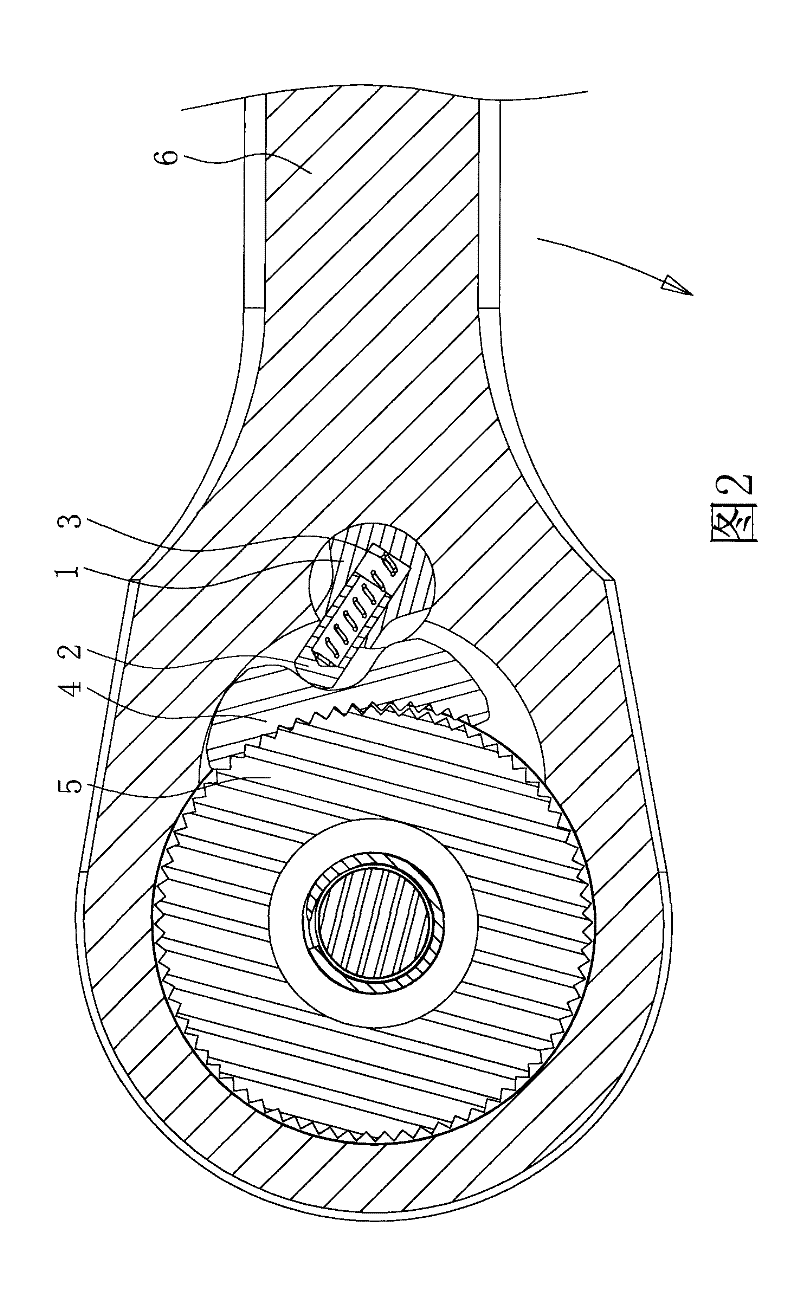

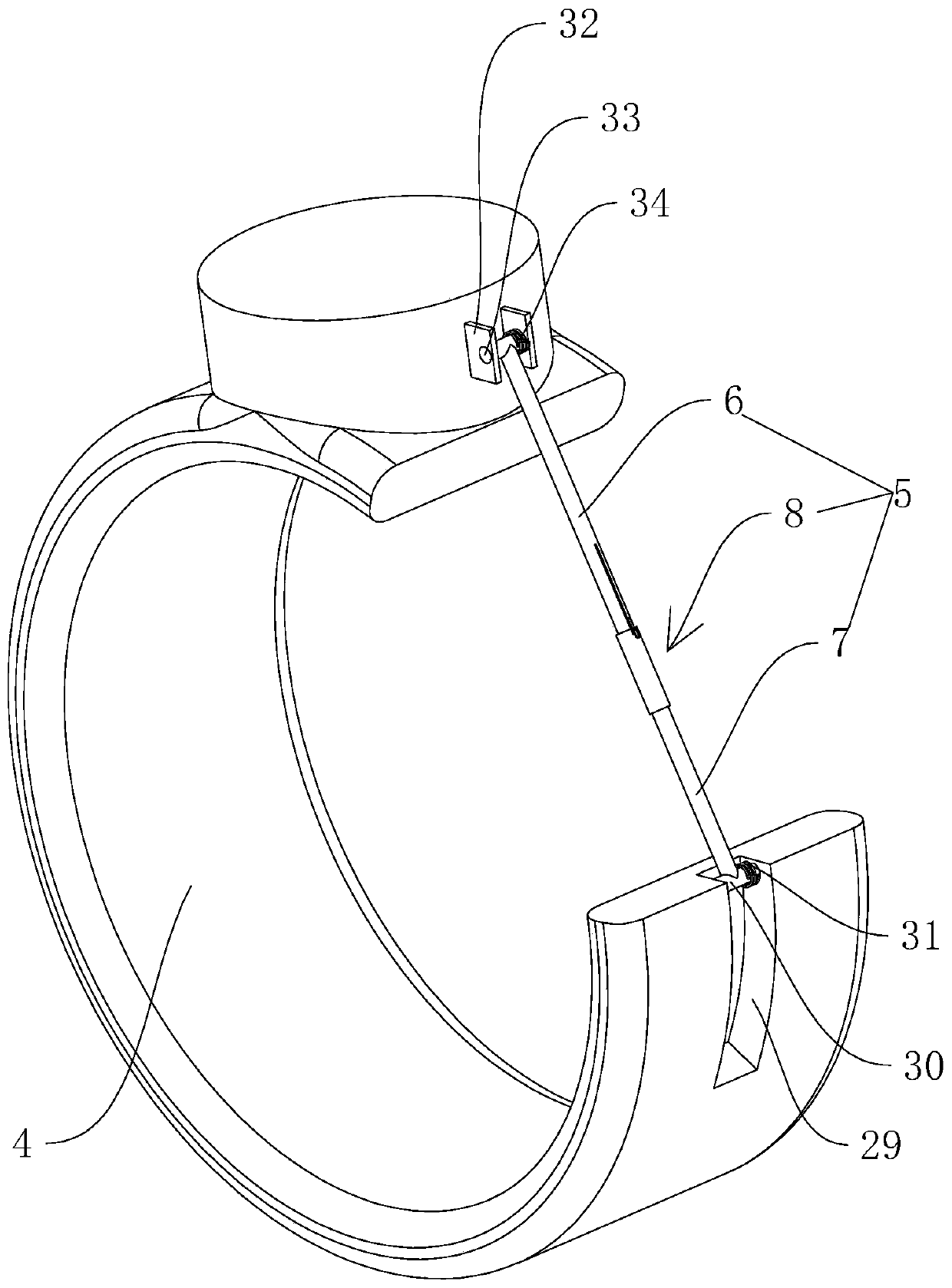

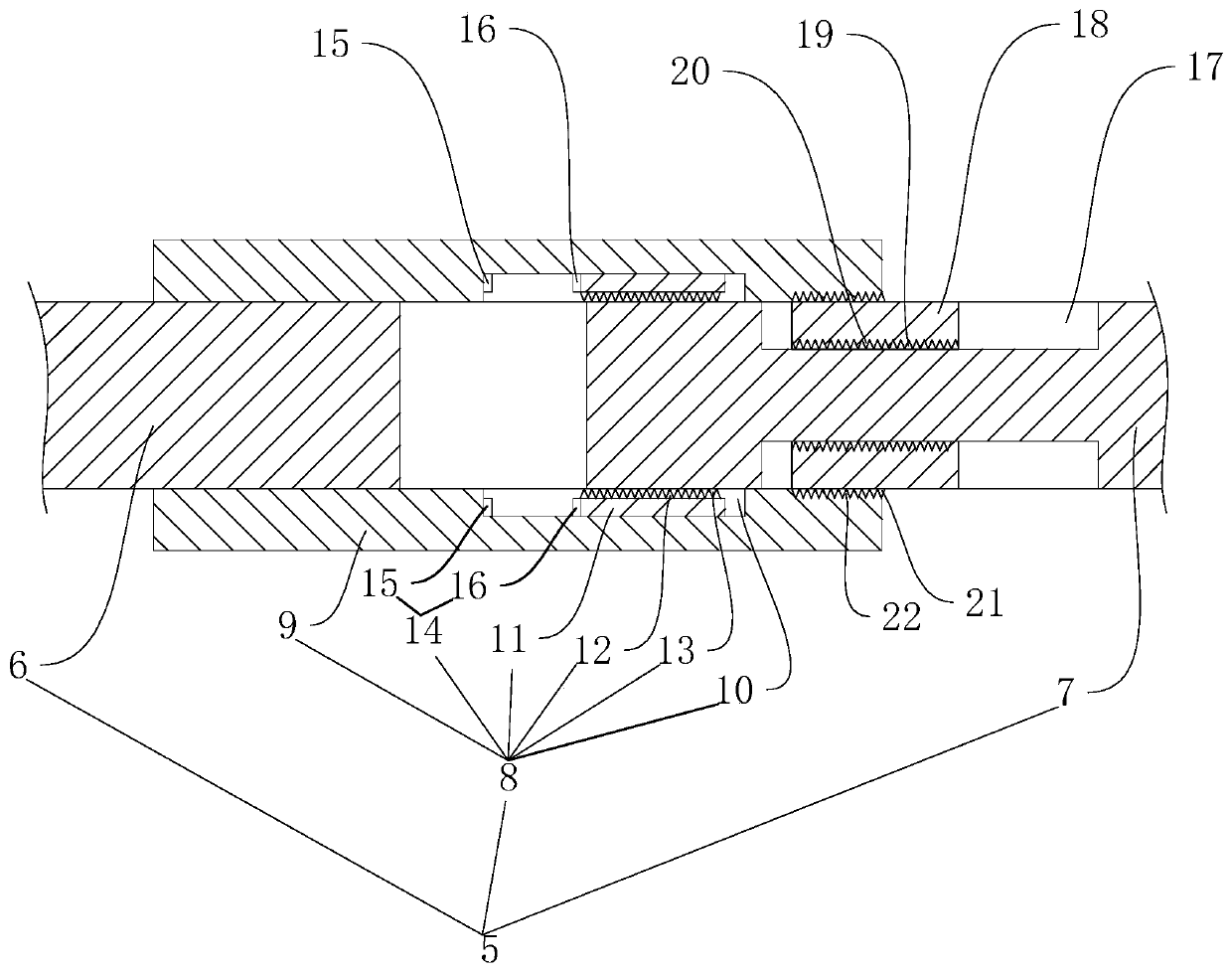

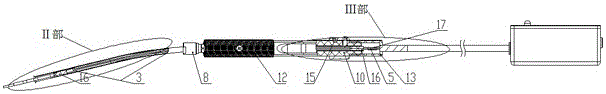

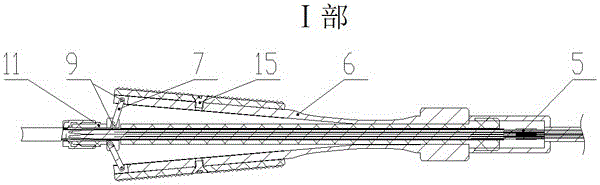

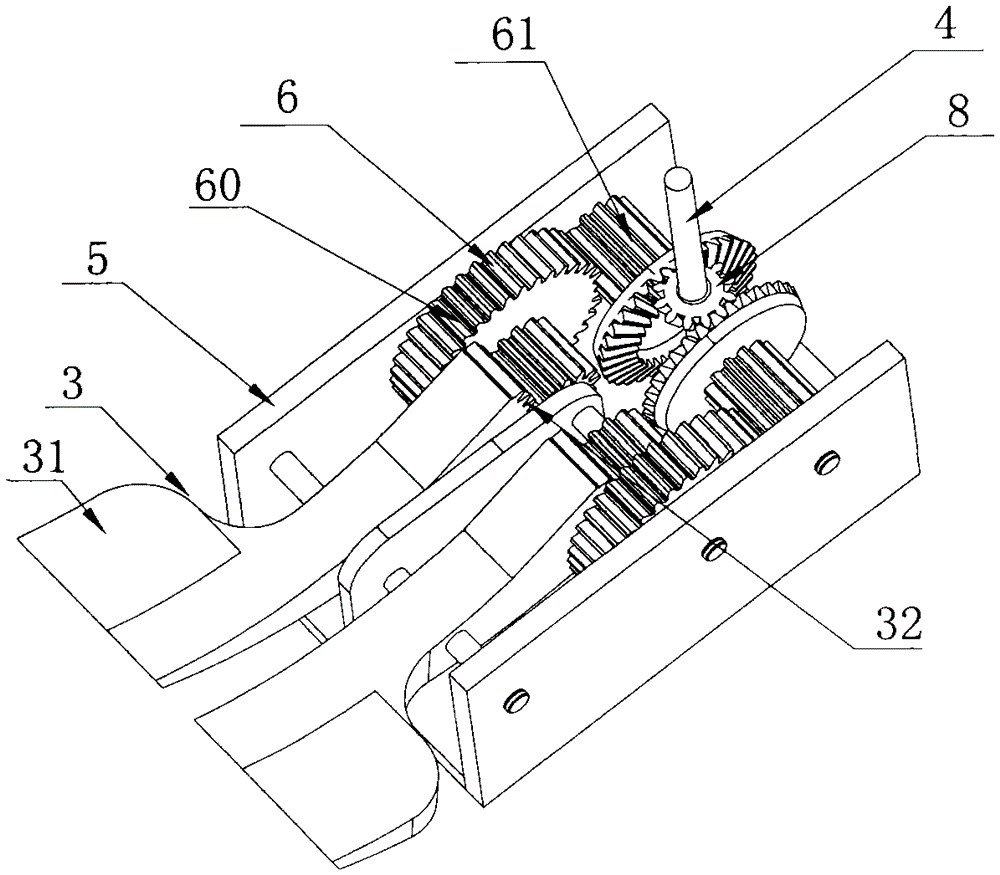

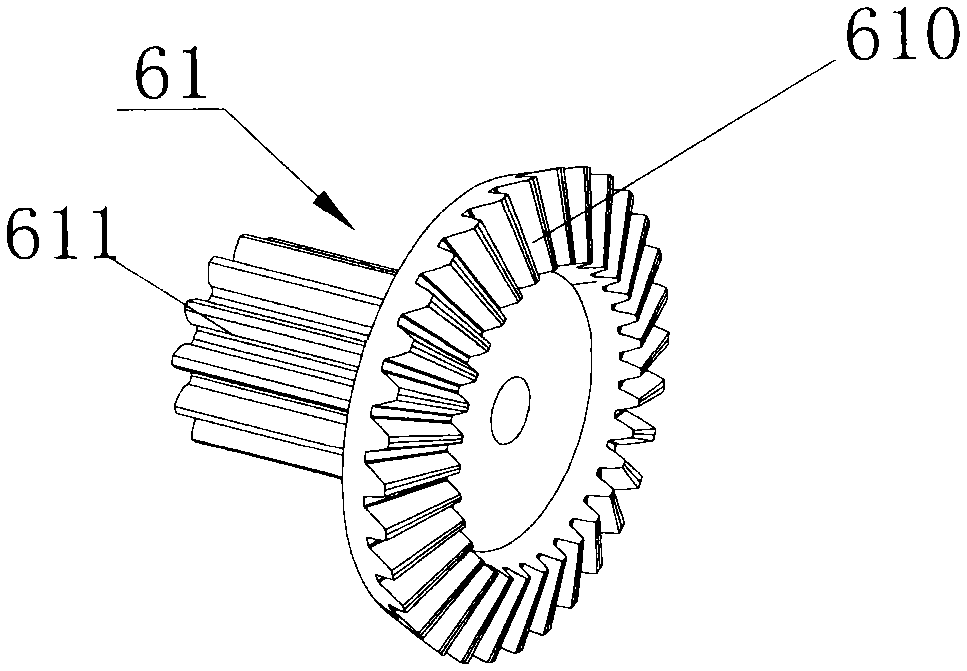

Intraoperative hemostasis electrode, endoscopic electrode

ActiveCN104224317BImprove mesh stabilityNo misalignmentSurgical instruments for heatingSurgical HemostasisSurgical treatment

The invention discloses a disposable hemostasis instrument, which comprises an electrode I (1) and an electrode II (2) arranged oppositely, a fixedly arranged inner tube (3), and an outer tube (4) sleeving the inner tube (3) and capable of moving relative to the inner tube (3), wherein the electrode I (1) and the electrode II (2) are arranged in the inner tube (3) and stretch out from the inner tube (3) and the outer tube (4); a conductor trace line (5) connected with the electrode I (1) and the electrode II (2) is arranged in the inner tube (3); a push device for enabling the outer tube (4) to move back and forth is arranged on the outer tube (4). The disposable hemostasis instrument has the advantages of innovative structure, reasonable design, flexibility and convenience in operation, thinner operating rod, and good hemostasis effect, and is applicable to deep surgical treatment of small passageways of all surgical departments especially minimally invasive microsurgery or neurological surgery.

Owner:JIANGSU HOPE BIOMEDICAL SCI & TECH CO LTD

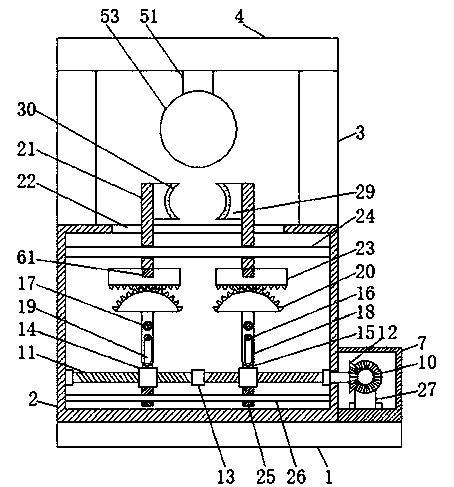

A multi-stage gear transmission system used in a stepping washing machine and the washing machine

ActiveCN102199861BEasy to useRealize zero consumptionOther washing machinesTextiles and paperGear driveGear wheel

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Shockproof and anti-drop Bluetooth noise reduction earphone shell

InactiveCN113365181AAvoid damageEliminate shockMicrophonesNon-rotating vibration suppressionTraction cordStructural engineering

The present invention discloses a shockproof and anti-drop Bluetooth noise reduction earphone shell. The shockproof and anti-drop Bluetooth noise reduction earphone shell. comprises a shell body and a sponge ring fixed to the right side of the shell body, the surface of the shell body is sleeved with a protective shell, a traction rope is arranged on the left side of the protective shell, and the top end and the bottom end of the traction rope extend to the outer side of the protective shell and penetrate into the protective shell. The two ends of the traction rope are fixedly connected with the surface of the shell, a compressed spring is fixedly connected to the left side of the shell, and the side, away from the shell, of the compressed spring makes contact with the inner wall of the protective shell. According to the Bluetooth earphone shell, the pulling rope and the pressure spring are arranged to support the shell and enable the shell to be separated from the protective shell, so that the pressure spring and the pulling rope can eliminate impact force by using deformation force when the Bluetooth earphone shell is subjected to falling impact, the shell is prevented from being damaged due to falling impact, and the problems are solved that an existing Bluetooth earphone shell is poor in shock-proof and anti-falling effect, the Bluetooth earphone shell is easy to damage due to collision after falling, so that the application range of the Bluetooth earphone shell is seriously influenced.

Owner:深圳市鑫精盟精密科技有限公司

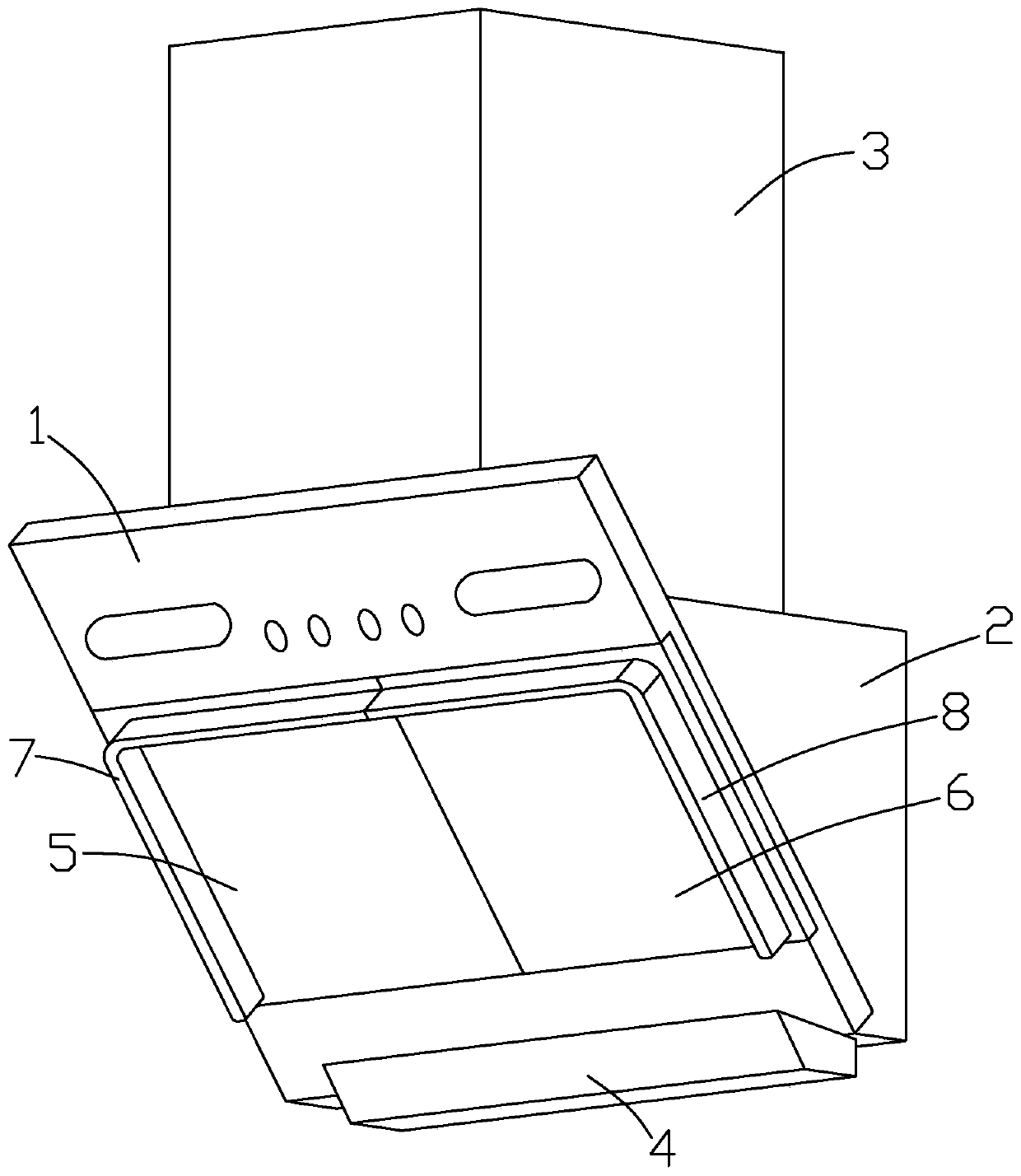

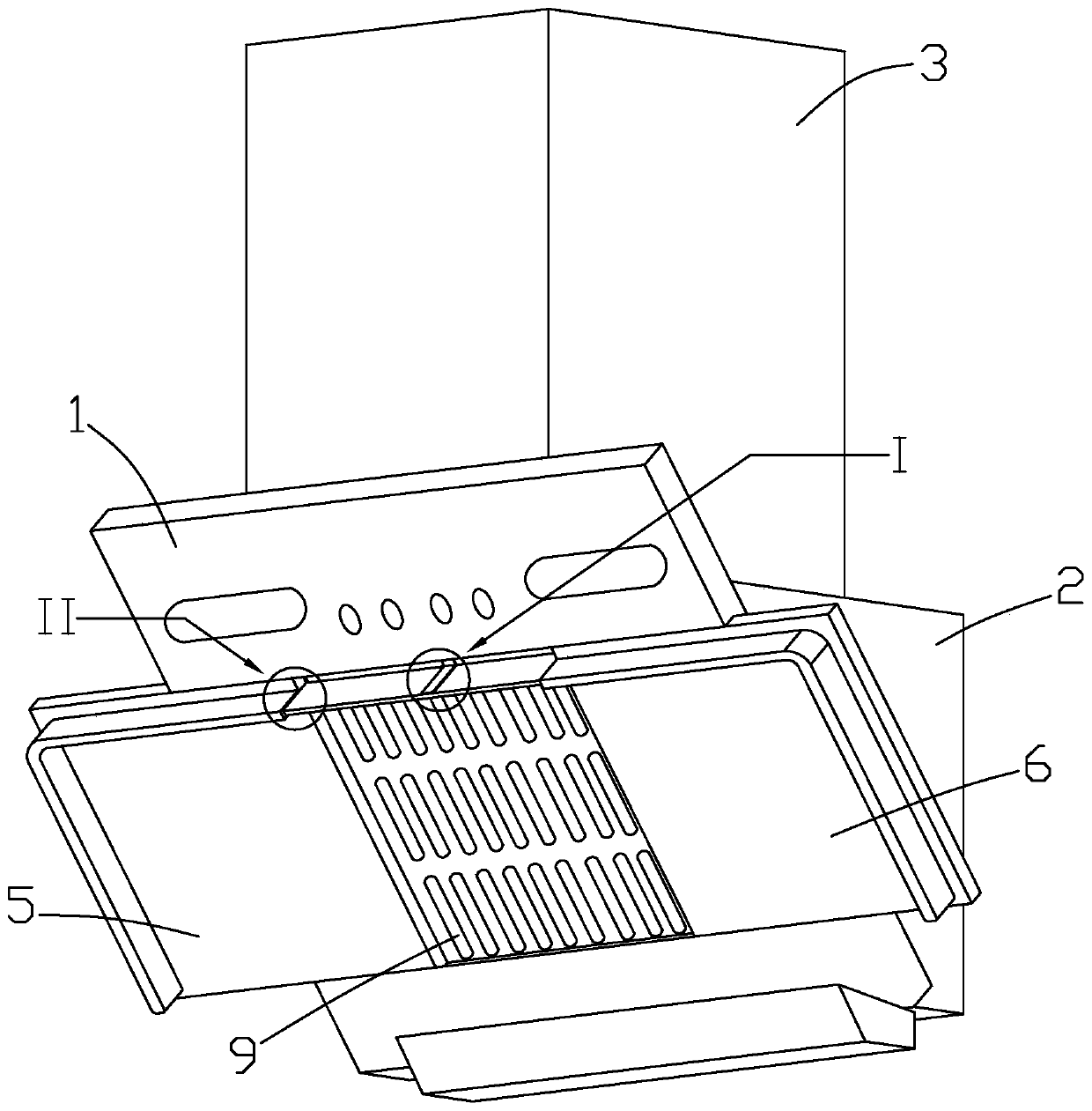

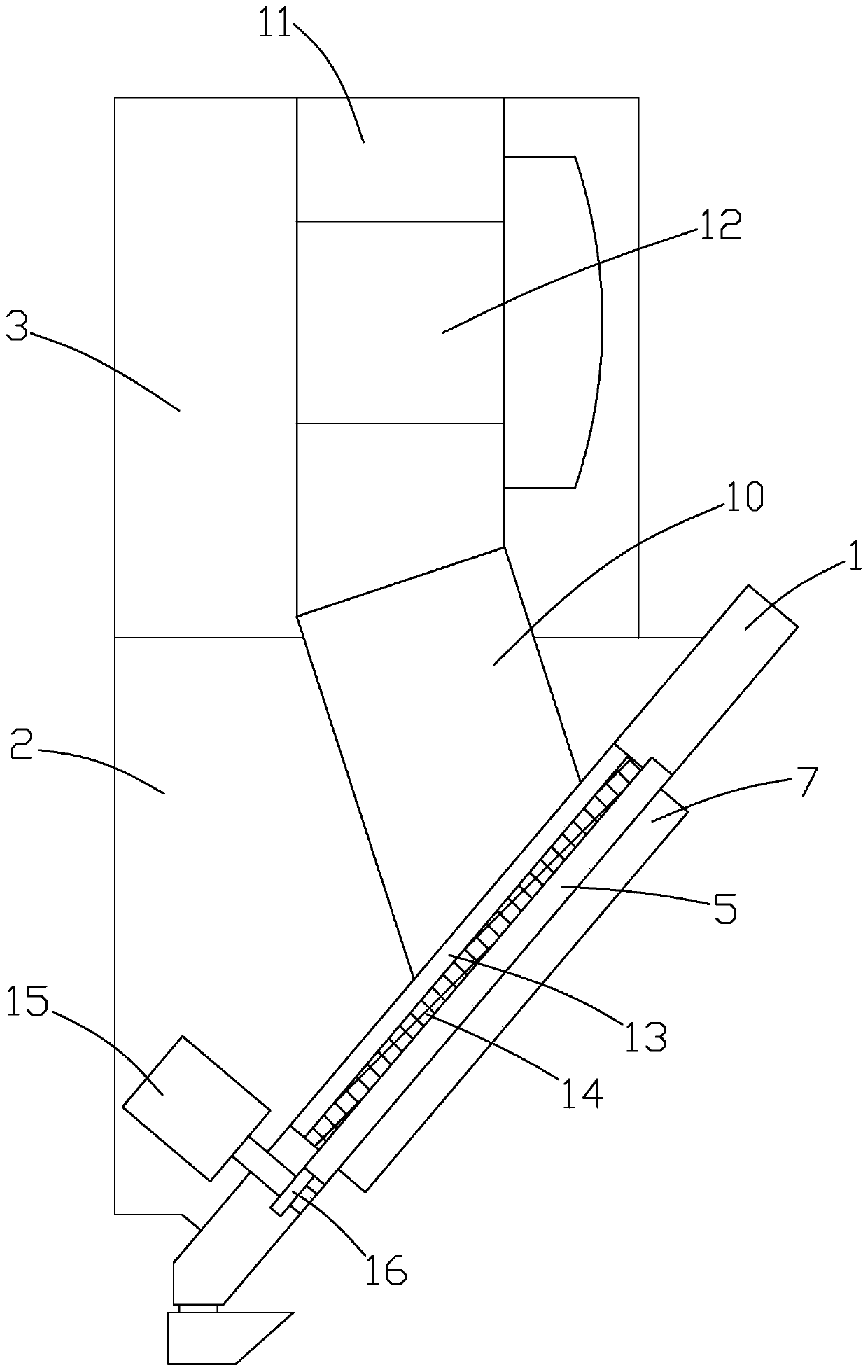

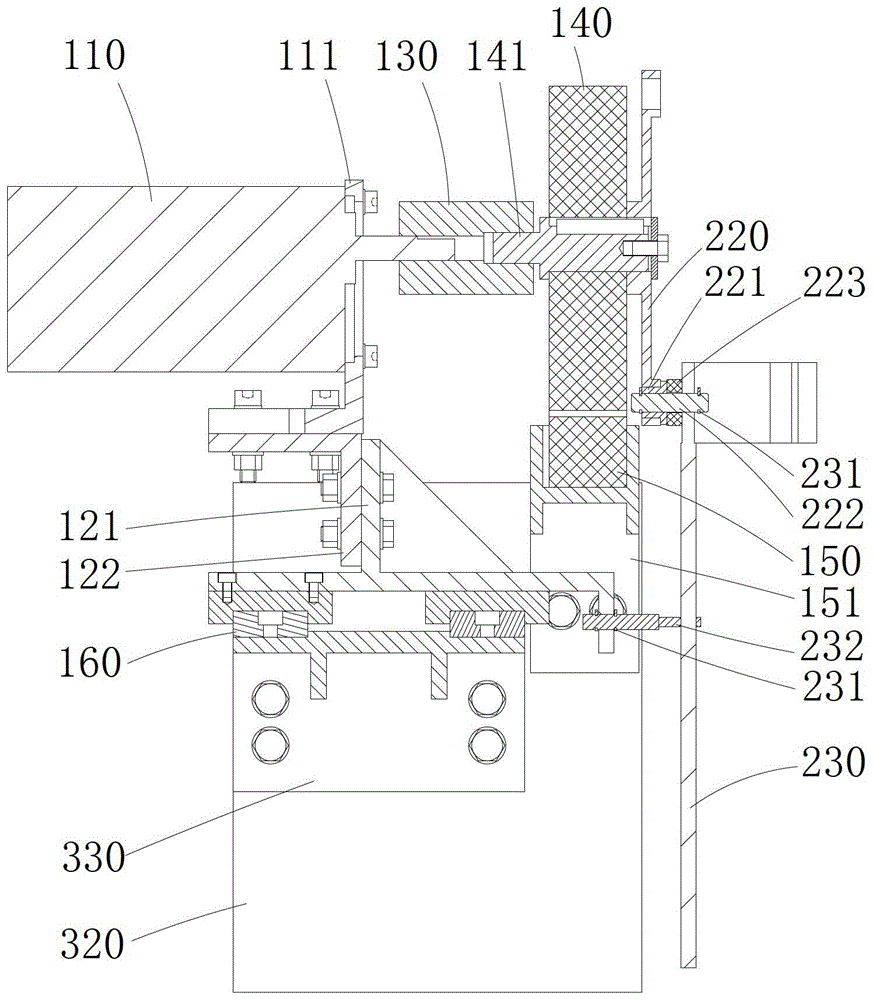

Extractor hood with moving door type smoke guide plates and manufacturing method thereof

ActiveCN110553294AImprove stabilityImprove reliabilityDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

The invention discloses an extractor hood with moving door type smoke guide plates and a manufacturing method thereof. The extractor hood with the moving door type smoke guide plate comprises a panel,a positioning box and a smoke discharge box, wherein a first smoke guide plate, a second smoke guide plate and a smoke absorbing plate are arranged on the front side surface of the panel; the first smoke guide plate and the second smoke guide plate are connected onto the panel through a horizontal moving mechanism, and are positioned at the outer side of the smoke absorbing plate; a first smoke guide bar and a second smoke guide bar are separately arranged on the first smoke guide plate and the second smoke guide plate; and a jointing bar is arranged between the first smoke guide plate and the second smoke guide plate. The manufacturing method for the extractor hood with the moving door type smoke guide plates comprises the following steps: panel processing, first smoke guide plate and second smoke guide plate mounting, positioning box processing, smoke discharge box processing and mounting and extractor hood pilot run. The extractor good can be closed while not working, so that dustis prevented from entering the extractor hood to bond with greasy dirt, and therefore, steam generated during cooking can be collected towards the smoke absorbing plate, and oil smoke is convenientlyabsorbed into the smoke absorbing plate to prevent smoke escape.

Owner:浙江玉禾电器有限公司

Swing device that moves with rhythm

InactiveCN104338321BLarge space for exerciseNot easy to shakeAmusementsAxial displacementMotion synthesis

The invention relates to a rhythmically moving rocking device. The rhythmically moving rocking device comprises a rhythm extraction module, a mounting body, a rocking driving module and a load connecting module; the sliding rail of the mounting body is provided with two ends, and the sliding platform of the mounting body is arranged on the sliding rail and slides between the two ends; the power mechanism of the rocking driving module is fixed with the sliding platform and controlled by the rhythm extraction module; the rolling mechanism of the rocking driving module comprises a rolling body and an input shaft; the circular rolling body is arranged on the sliding platform; the input shaft is fixed at the center of the rolling body; the power mechanism drives the input shaft to rotate and the rolling body rolls along the sliding rail; the connecting mechanism of the load connecting module is fixed on the rolling mechanism; the rocking part of a rocking mechanism is connected to a connection mechanism by use of the rotating shaft of the rocking mechanism, and a first axial positioner is used for limiting axial displacement to achieve the purpose of multiple motion synthesis.

Owner:中科英华湖州工程技术研究中心有限公司

Ratchet wheel with protection and identification layers and manufacturing method thereof

The invention provided a ratchet wheel with protection and identification layers and a manufacturing method thereof. A comprehensive protection coating and a localized identification coating can be mainly formed on the surface of the ratchet wheel by two electroplating processes. The protection coating has a high bonding force (or adhesion) with the ratchet wheel and is not prone to falling off, and the abrasion resistance, oxidation resistance and surface gloss of the ratchet wheel are improved. The identification electroplated layer plays a role for the user to visually identify the ratchetwheel, and the specification and size of the ratchet wheel or a ratchet wrench are determined by the color of the identification electroplated layer.

Owner:陈怡富

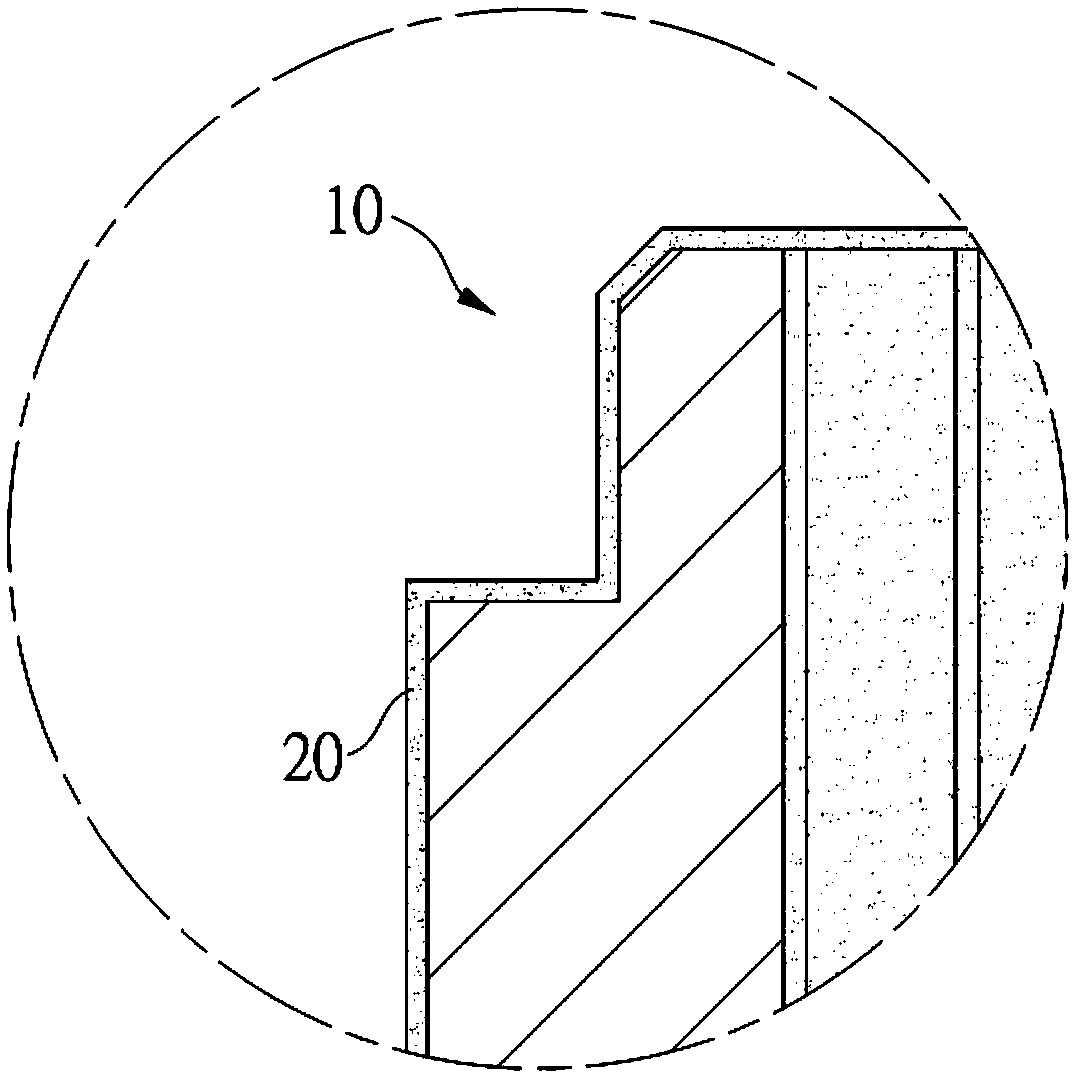

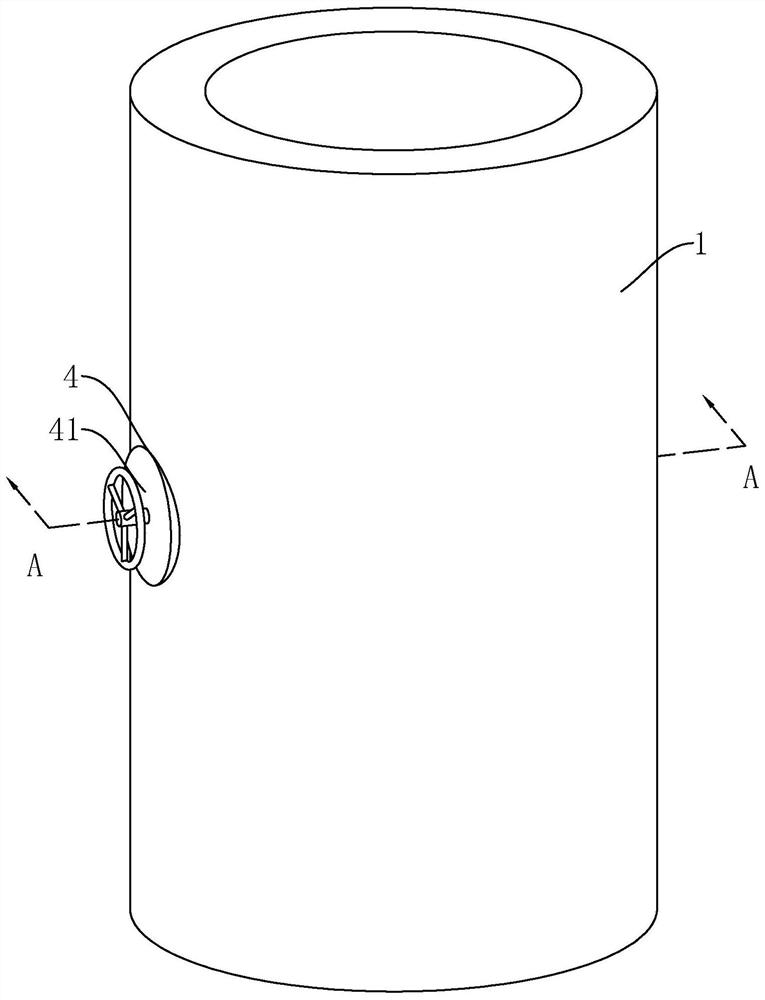

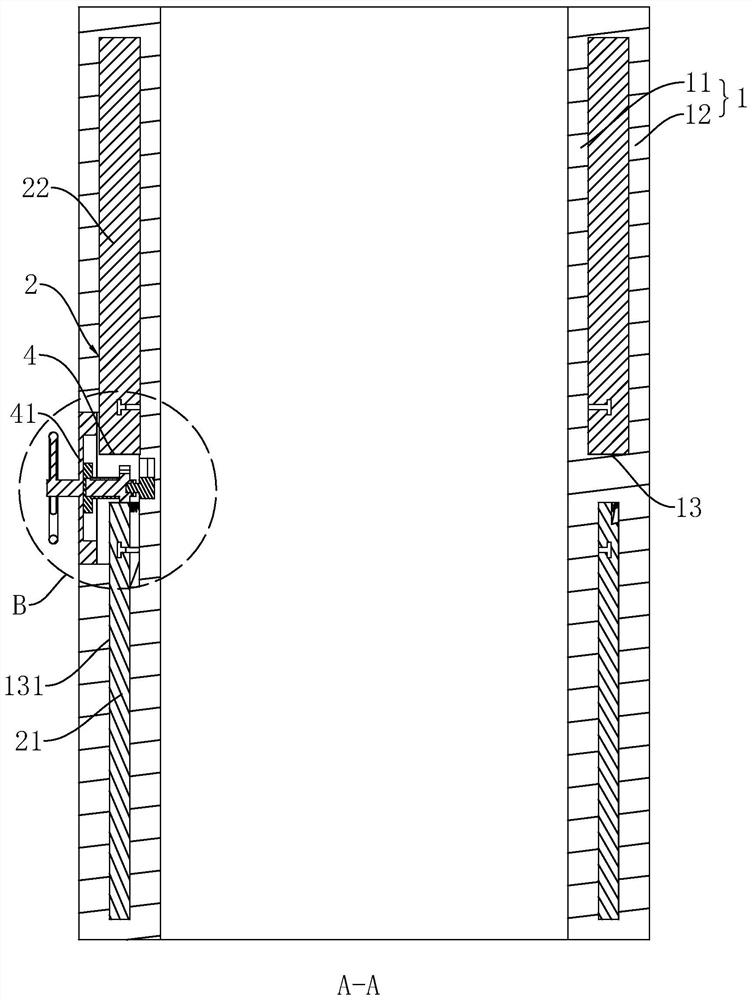

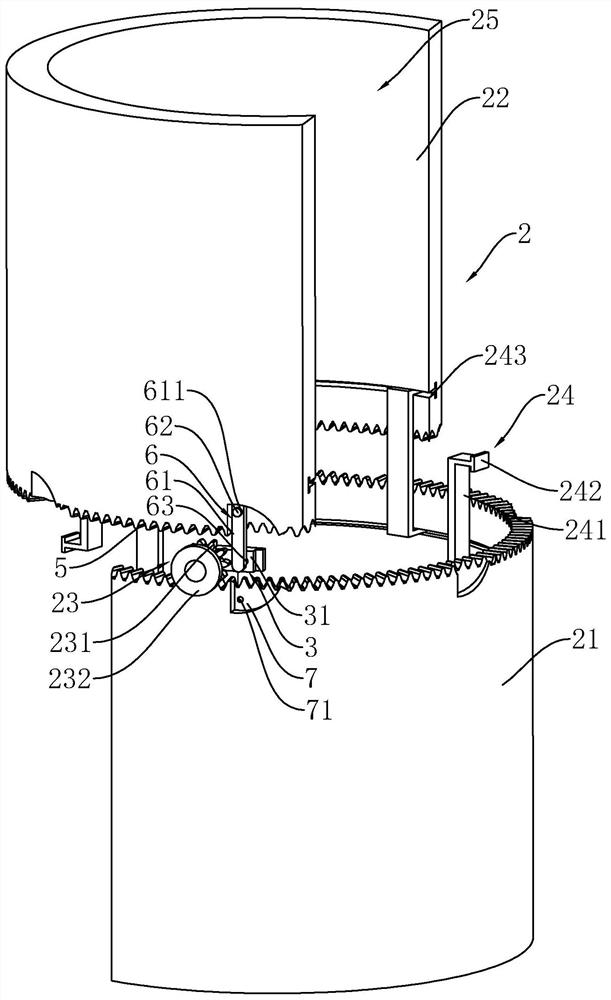

A self-supporting ring-shaped closed environmental protection precast concrete wall panel

This application relates to a self-supporting annular closed environmental protection prefabricated concrete wall panel, which includes an annular wall and a supporting steel structure arranged in the wall, the wall includes an inner layer of the wall and an outer layer of the wall, and the supporting steel structure It is arranged between the inner layer of the wall and the outer layer of the wall, the supporting steel structure is ring-shaped, and the supporting steel structure extends along the outer circumferential direction of the inner layer of the wall. The ring-shaped fixed steel structure is used to support the prefabricated concrete wall panels to improve the firmness of the concrete walls and make the concrete walls not easily broken when hoisted. Set the gear, the teeth on the first missing ring steel plate and the teeth on the second missing ring steel plate, so that the first missing ring steel plate and the second missing ring steel plate can rotate in the concrete wall, adjust the position of the gap, and facilitate opening for Install door slots.

Owner:浙江高盛钢结构有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com