Elastic supporting bearing structure

An elastic support and bearing technology, applied in steering mechanism, electric steering mechanism, power steering mechanism, etc., can solve the problem that the steel ball of the elastic support bearing unit cannot be stably guided, the meshing position of the worm gear is wrong, and the force in the meshing area is uneven, etc. problem, to achieve the effect of simple structure, extended service life and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

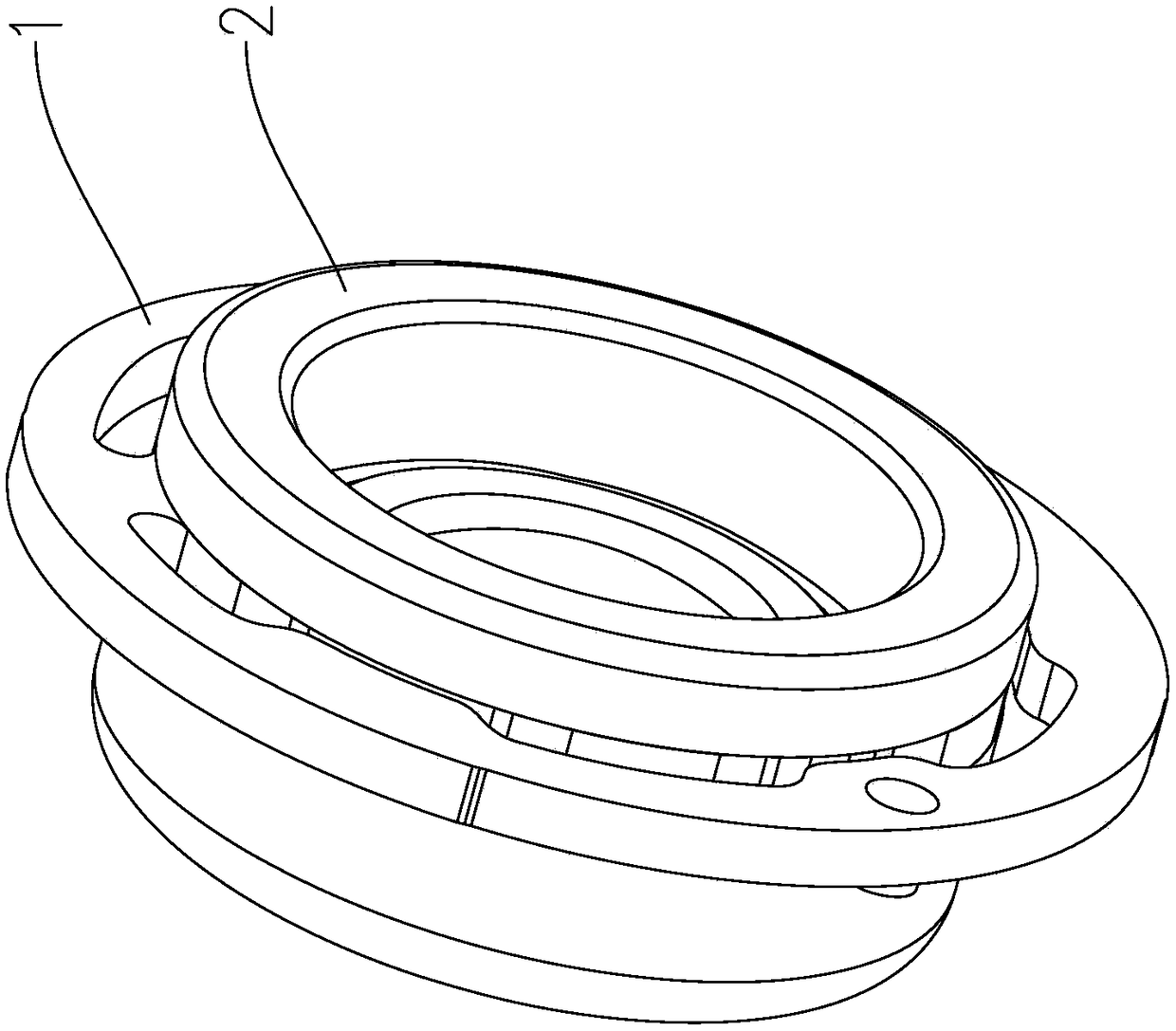

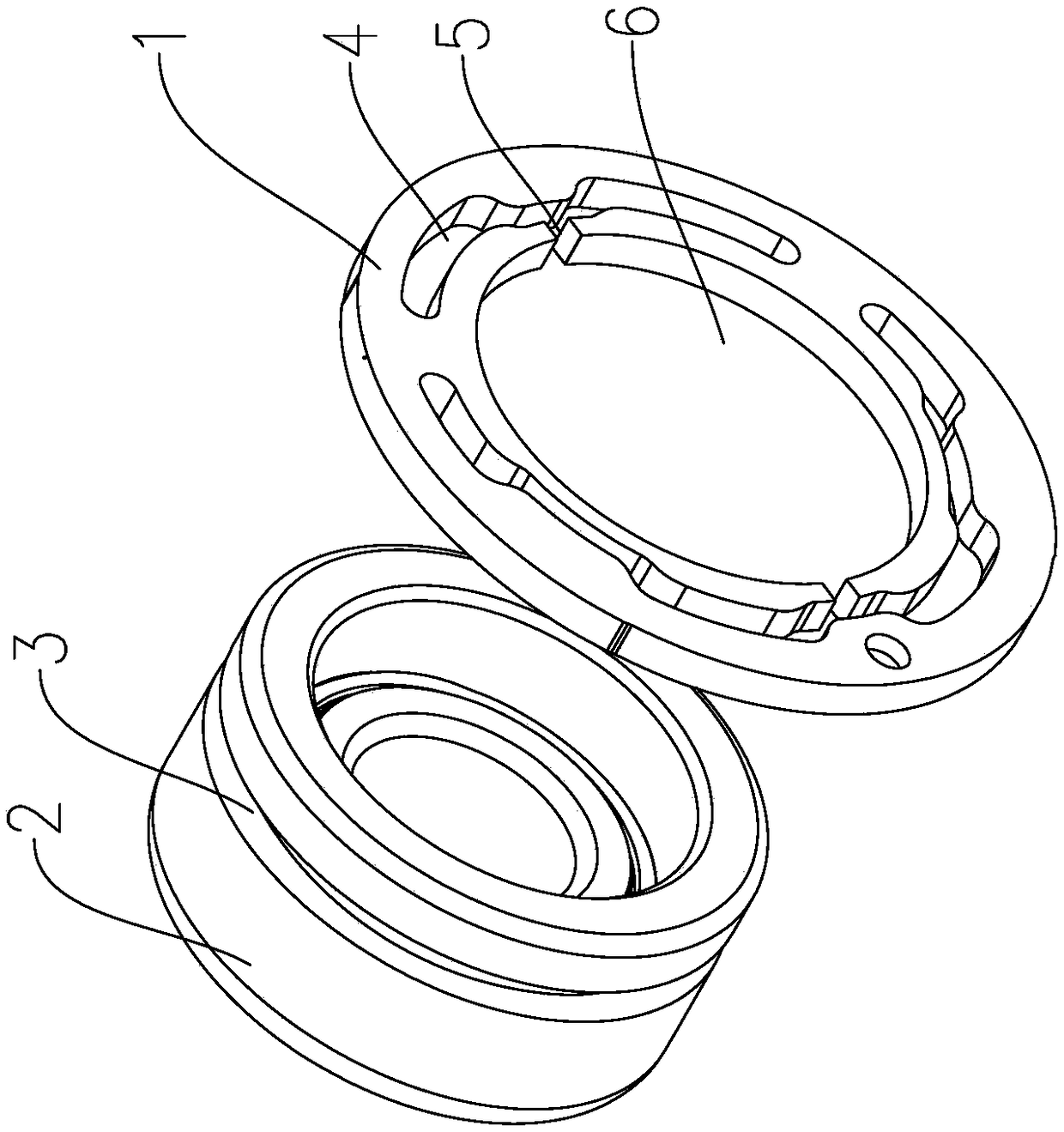

[0017] Such as Figure 1~4 As shown, the present invention mainly includes a floating elastic block 1 and a ball bearing 2. A stop groove 3 is provided on the outer peripheral surface of the ball bearing 2, and the floating elastic block 1 is embedded in the stop groove 3 of the ball bearing 2.

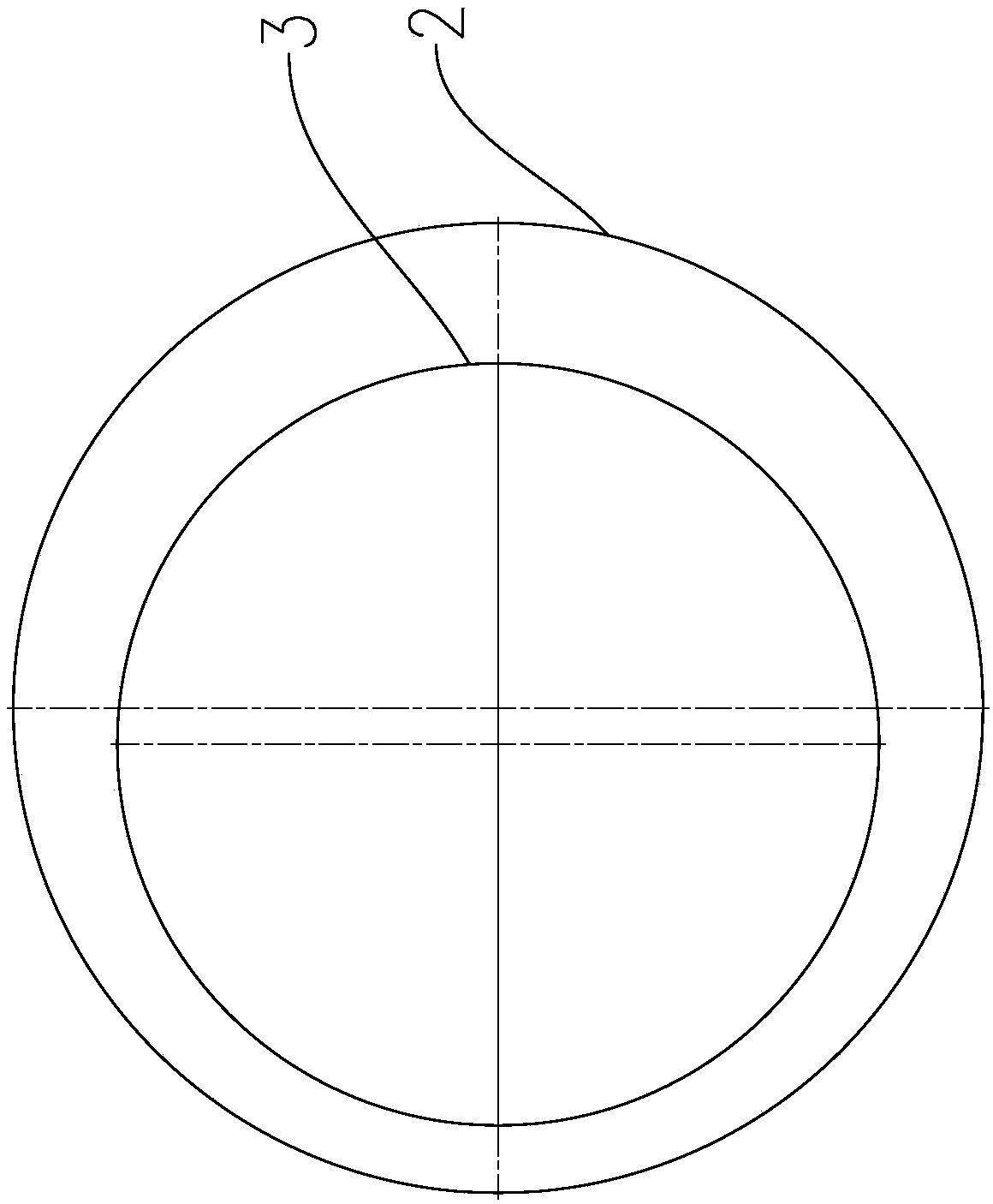

[0018] In order to prevent the floating elastic block 1 from freely rotating in the stop groove 3 of the ball bearing 2, the stop groove 3 is an eccentric groove, and the center of the circle where the stop groove 3 is located deviates from the circle center of the outer circumference of the ball bearing 2 by a certain distance.

[0019] The center of the floating elastic block 1 is provided with an installation cavity 6 , and at least one elastic groove 4 is arranged on the floating elastic block 1 , and the elastic groove 4 is arranged along the circumferent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com