Novel lock ring synchronizer gearbox with ten-gear dual-intermediate shaft

A technology of double intermediate shafts and synchronizers, which is applied to transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of driver fatigue, low assembly bearing capacity, and small synchronization capacity, etc., and achieve improved Main box load capacity, reduction of shifting force, reduction of meshing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

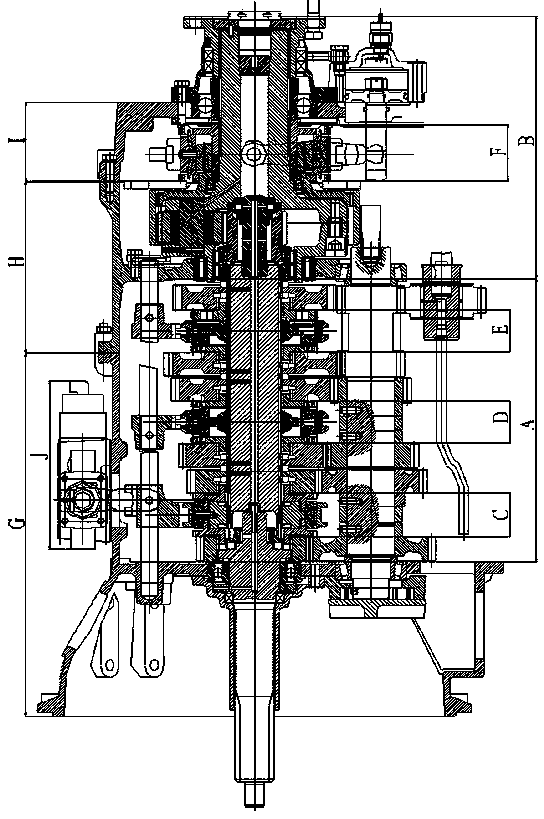

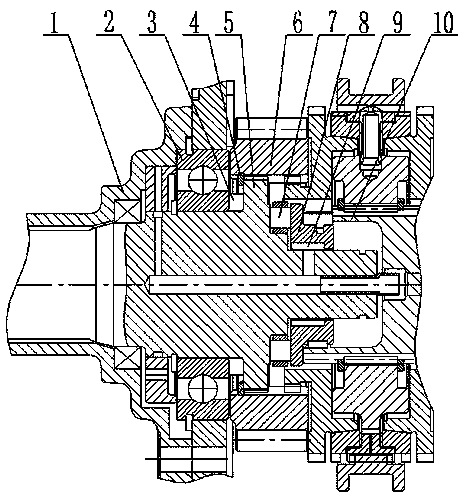

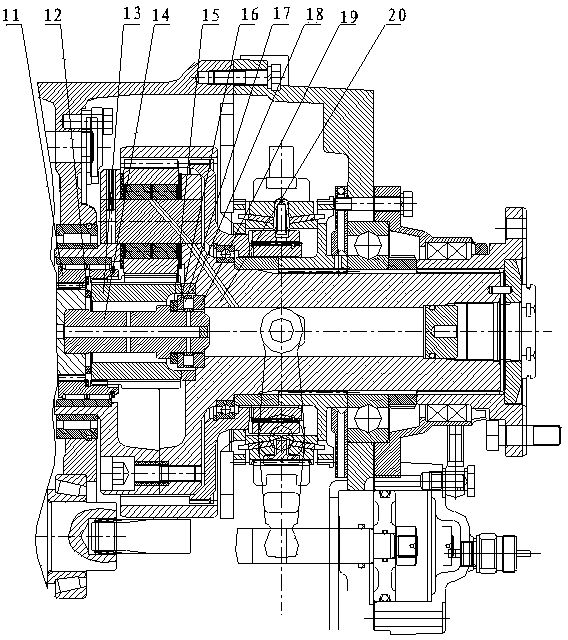

[0015] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The novel 10-speed helical double intermediate shaft lock-ring synchronizer gearbox disclosed in the present invention includes a main box A and an auxiliary box B. The main box A is provided with an input shaft 5 and a main shaft 10 connected to the input shaft 5. The main shaft 10 The spline transition sleeve 11 is connected to the sun gear 13 in the auxiliary box B. The front and rear ends of the main shaft 10 are respectively provided with a main shaft front positioning mechanism and a main shaft rear positioning mechanism. The main shaft 10 is provided with a shift helical gear set; 10 is equipped with fourth and fifth gear single cone lock ring synchronizers C, second and third gears are equipped with second and third gear double cone lock ring synchronizers, and reverse first gear is equipped with reverse first gear double cone lock r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com