Low-speed high-power marine engine timing chain

A marine engine, high-power technology, applied in the field of chain transmission, can solve the problems of affecting normal meshing, not taking into account, aggravating mutual wear of parts, etc., to achieve the effect of enhancing meshing stability, facilitating production inspection, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

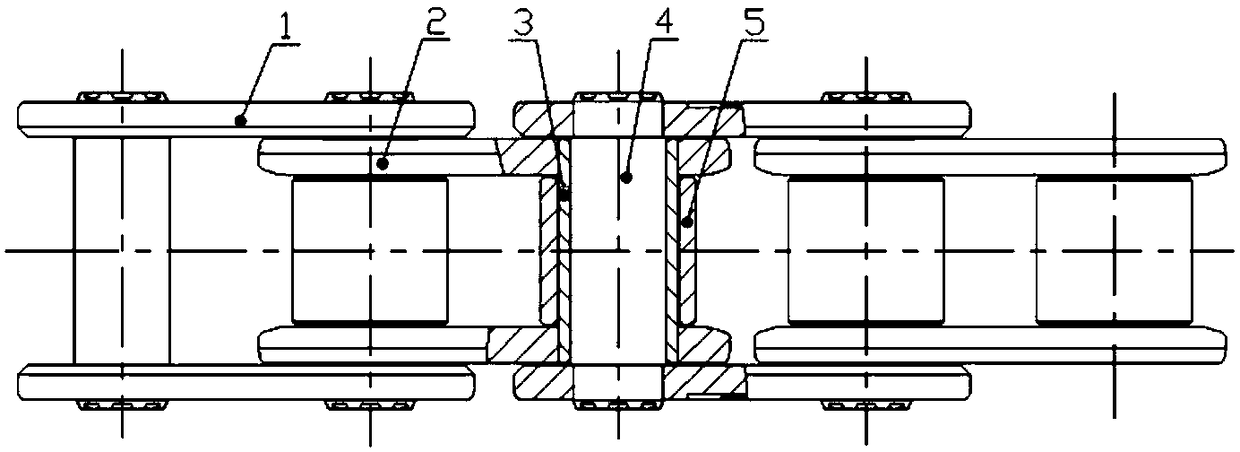

[0017] The invention will be further described below in conjunction with the description of the drawings and the embodiments: a low-speed high-power marine engine timing chain, including an inner chain plate 2 and a sleeve 3 interference fit and the sleeve 3 and the roller 5 clearance fit. The outer chain link formed by the interference fit of the chain link, the outer chain plate 1 and the pin shaft 4, the pin shaft 4 passes through the sleeve 3 to realize the interlacing and mutual embedding of the inner chain link and the outer chain link.

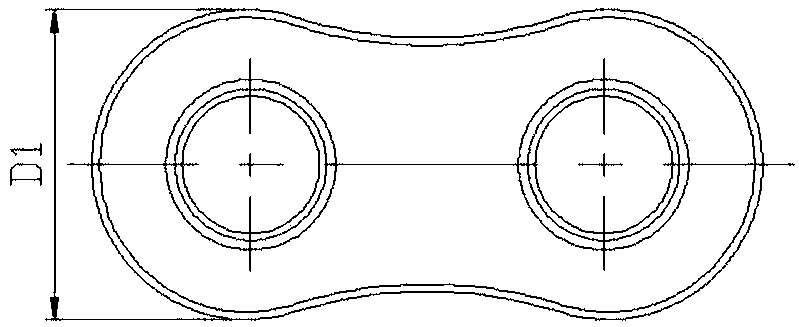

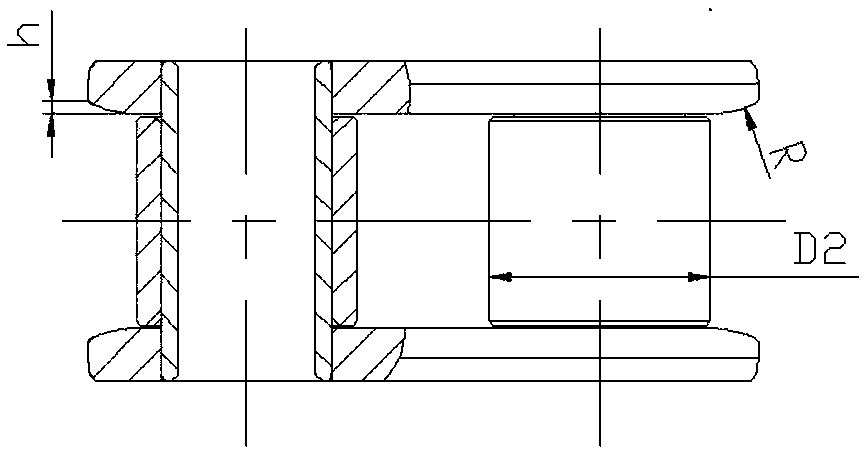

[0018] The engagement fillet radius R of the inner chain plate 2, the outer circular arc diameter D1 of the chain plate and the outer diameter D2 of the roller 5 satisfy the relationship: R=(70%-95%)×(D1-D2). The meshing fillet height h of the inner chain plate 2 is 20%-40% of the thickness of the chain plate.

[0019] The sleeve 3 adopts a tapered structure design at both ends, and the length L of the tapered area and the height H of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com