Gear

A gear, gear body technology, applied to gears. It can solve problems such as affecting the stability of gear meshing, easy interference of teeth, reducing bending strength of teeth on gears, etc., to achieve the effect of increasing installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

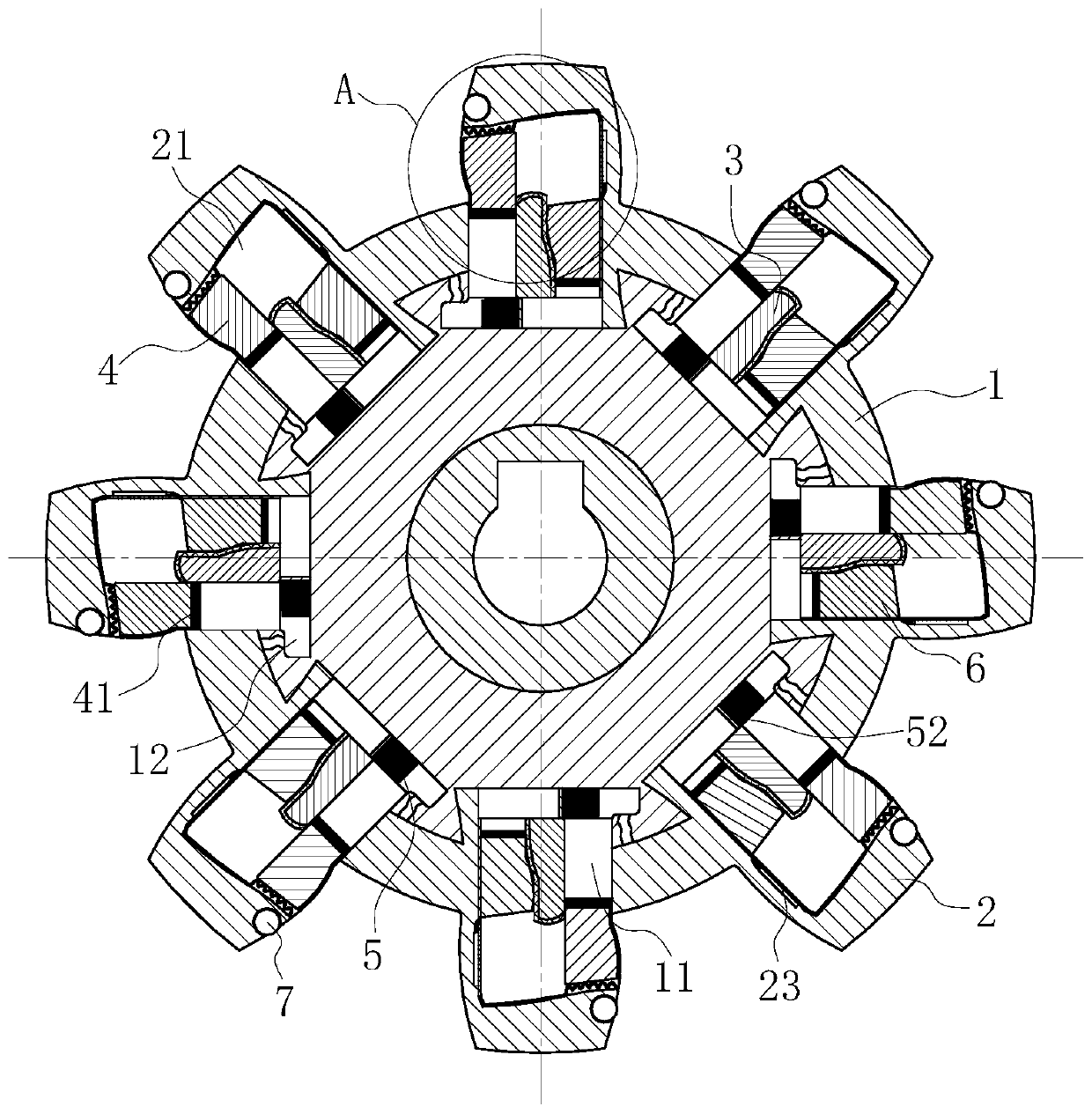

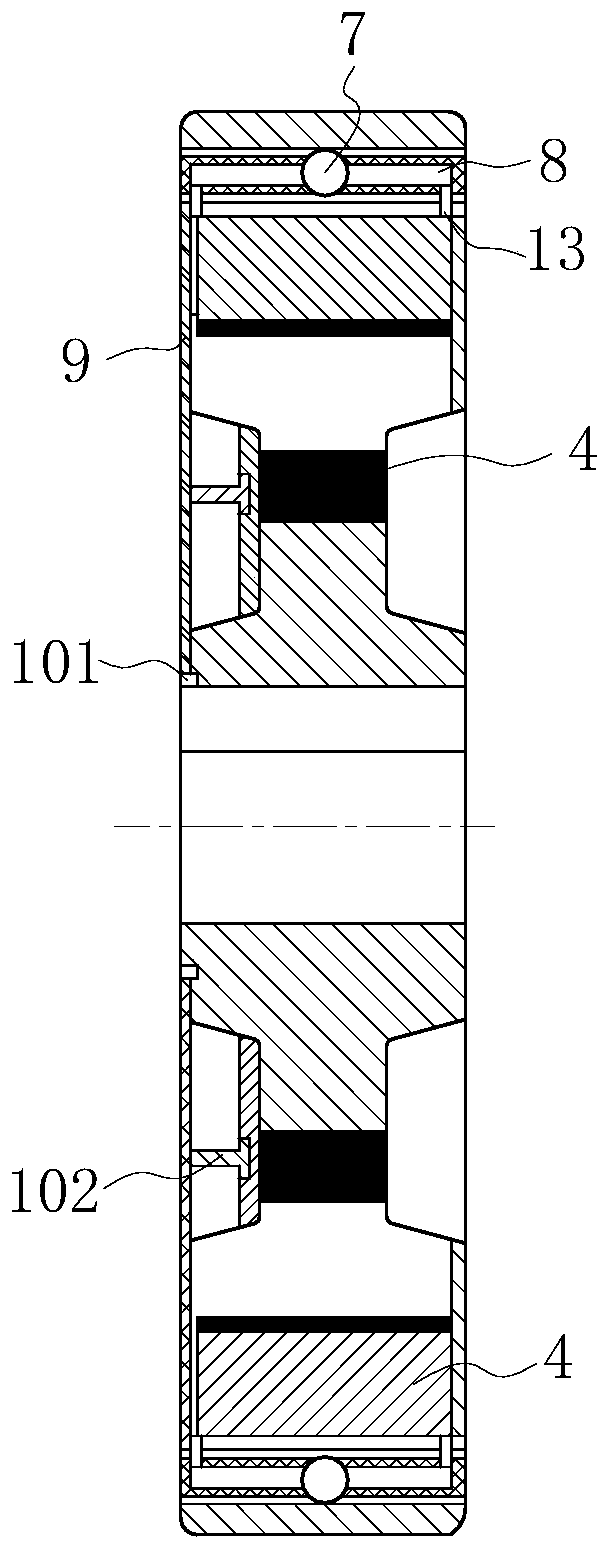

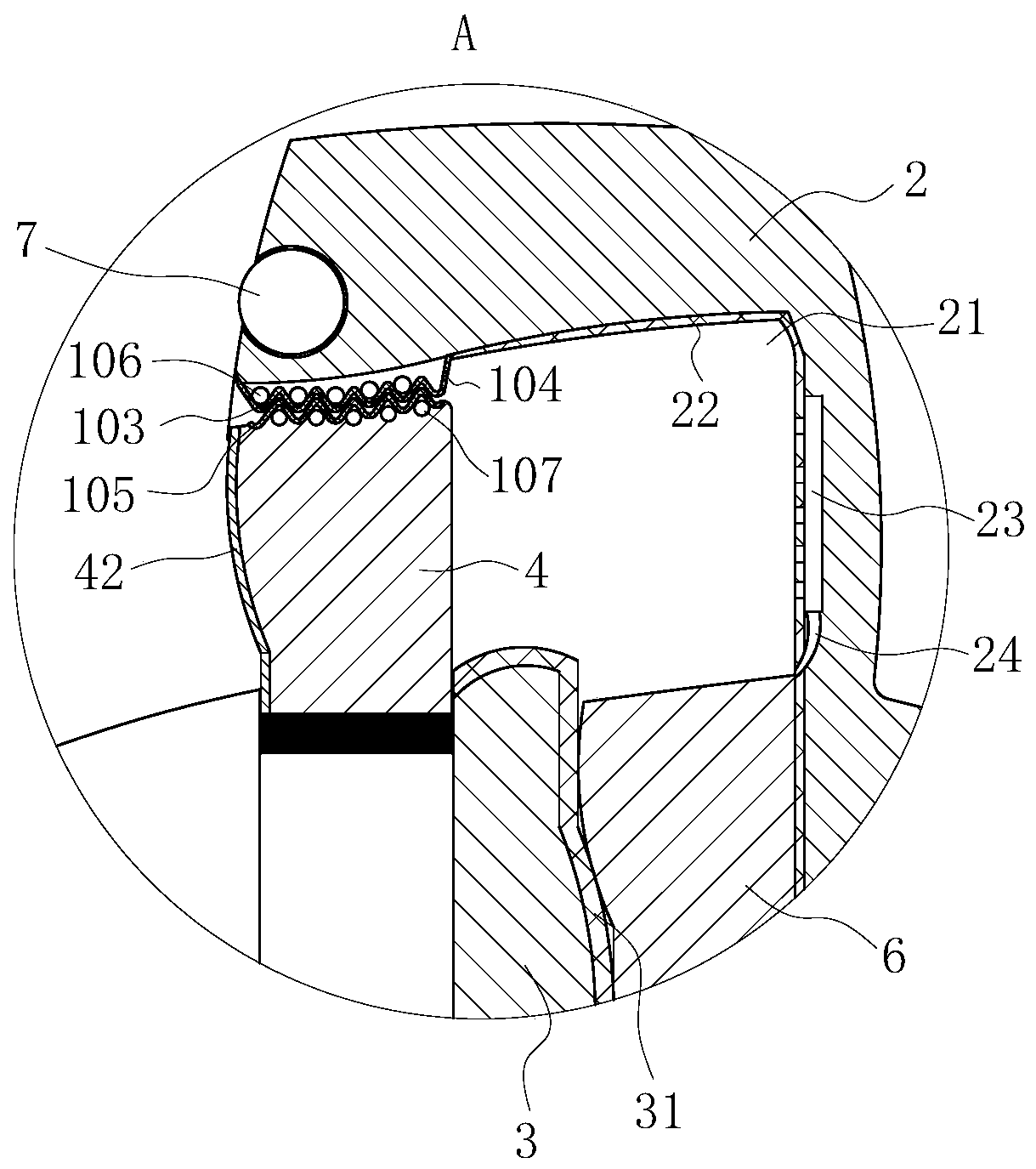

[0020] use Figure 1-Figure 3 A gear according to one embodiment of the present invention will be described below.

[0021] Such as figure 1 , figure 2 and image 3As shown, a gear of the present invention includes a gear body 1; the gear body 1 is evenly provided with teeth 2; it is characterized in that: the gear body 1 is uniformly provided with a sliding cavity 11, and the sliding cavity 11 are provided with a partition plate 3; the inside of the teeth 2 is provided with a sliding groove 21, and the sliding groove 21 communicates with the sliding chamber 11; a friction block 4 is arranged in one side of the sliding groove 21, and the friction block The bottom end of the 4 is provided with a magnet layer 41, and the outer surface of the friction block 4 is provided with an arc-shaped wear-resistant layer 42; the friction block 4 is inserted into the sliding cavity 11, and the width of the bottom end of the friction block 4 is equal to that of the barrier block and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com