Ceramic Live Working Tools

A live operation and live operation technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of affecting work safety, damaging the insulation effect, increasing costs, etc., and achieving the effects of convenient use, excellent waterproofness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

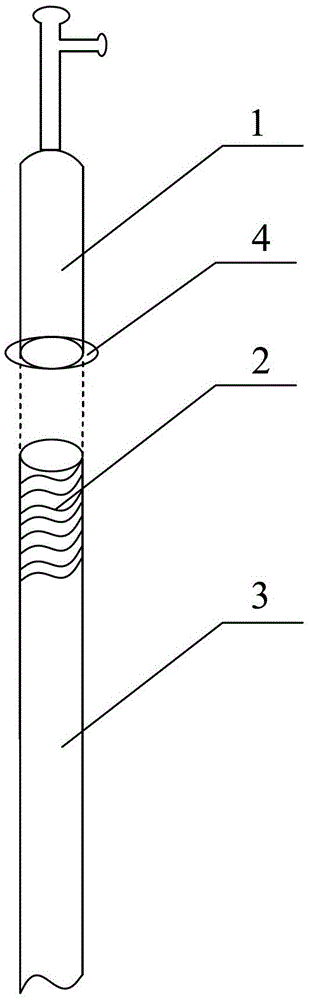

[0012] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0013] Such as figure 1 The ceramic live working tool shown includes a polyester insulating operating rod 3, and a live operating head is installed on the polyester insulating operating rod 3. The live operating head is a ceramic head 1, and the end of the ceramic head 1 is hollow and connected to the polyester insulating operating rod 3. Detachable connection. The rod head of the polyester insulated operating rod is provided with threads, and is detachably connected with the ceramic head 1 through the threads 2 . The live operation head can be a ceramic high-branch sickle, ceramic scissors, ceramic machete, ceramic pin puller or other live operation head. The live operation head has an integrated structure, and its one-time molding has better use effect. To carry out different live work, it only needs to disassemble and replace the corresponding working head....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com