Rivet setter

A technology of assembler and rivet, which is applied in transportation and packaging, spring/shock absorber, vibration suppression adjustment, etc., can solve undisclosed problems, achieve the effect of reducing cycle time and suppressing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described with reference to the accompanying drawings.

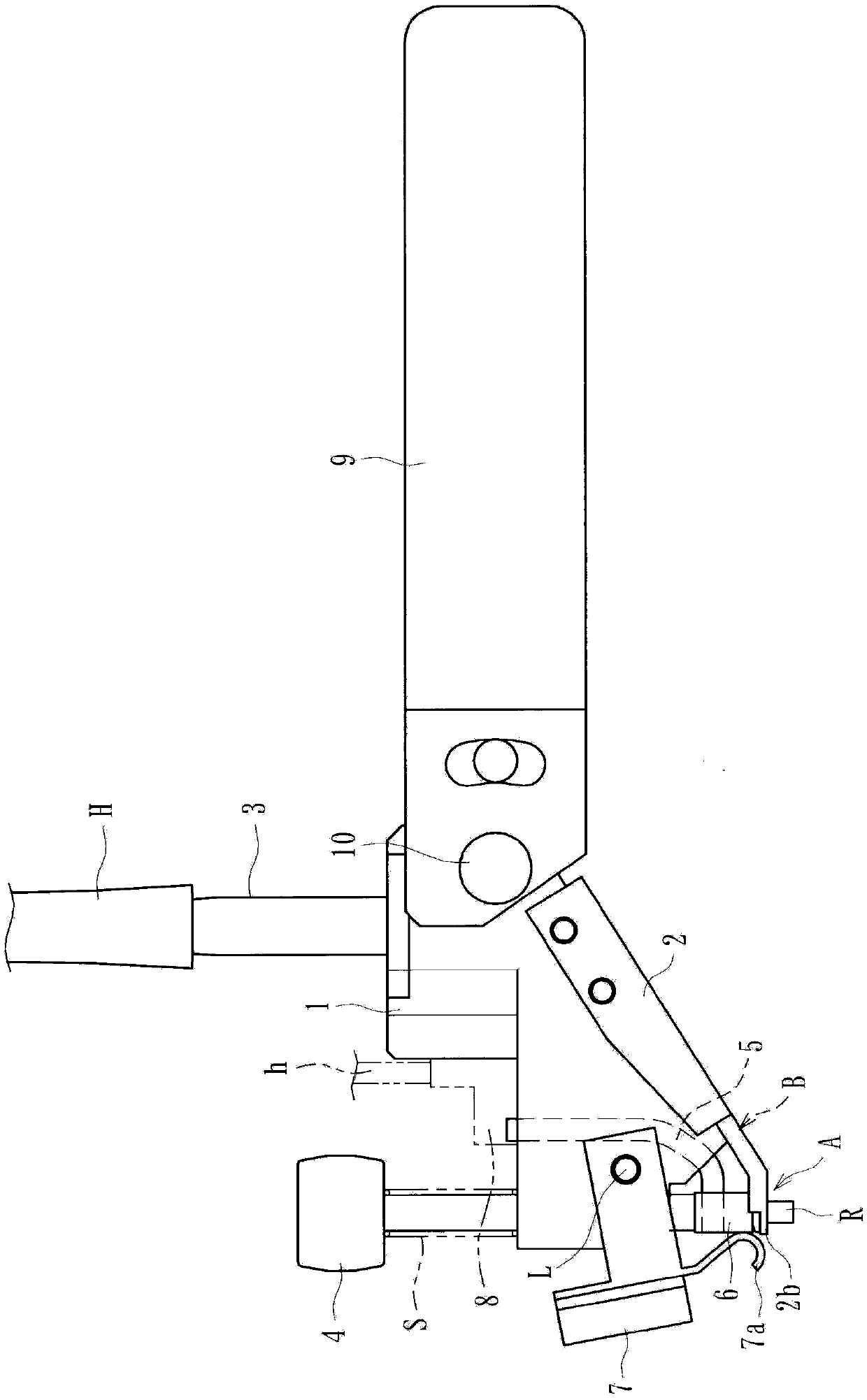

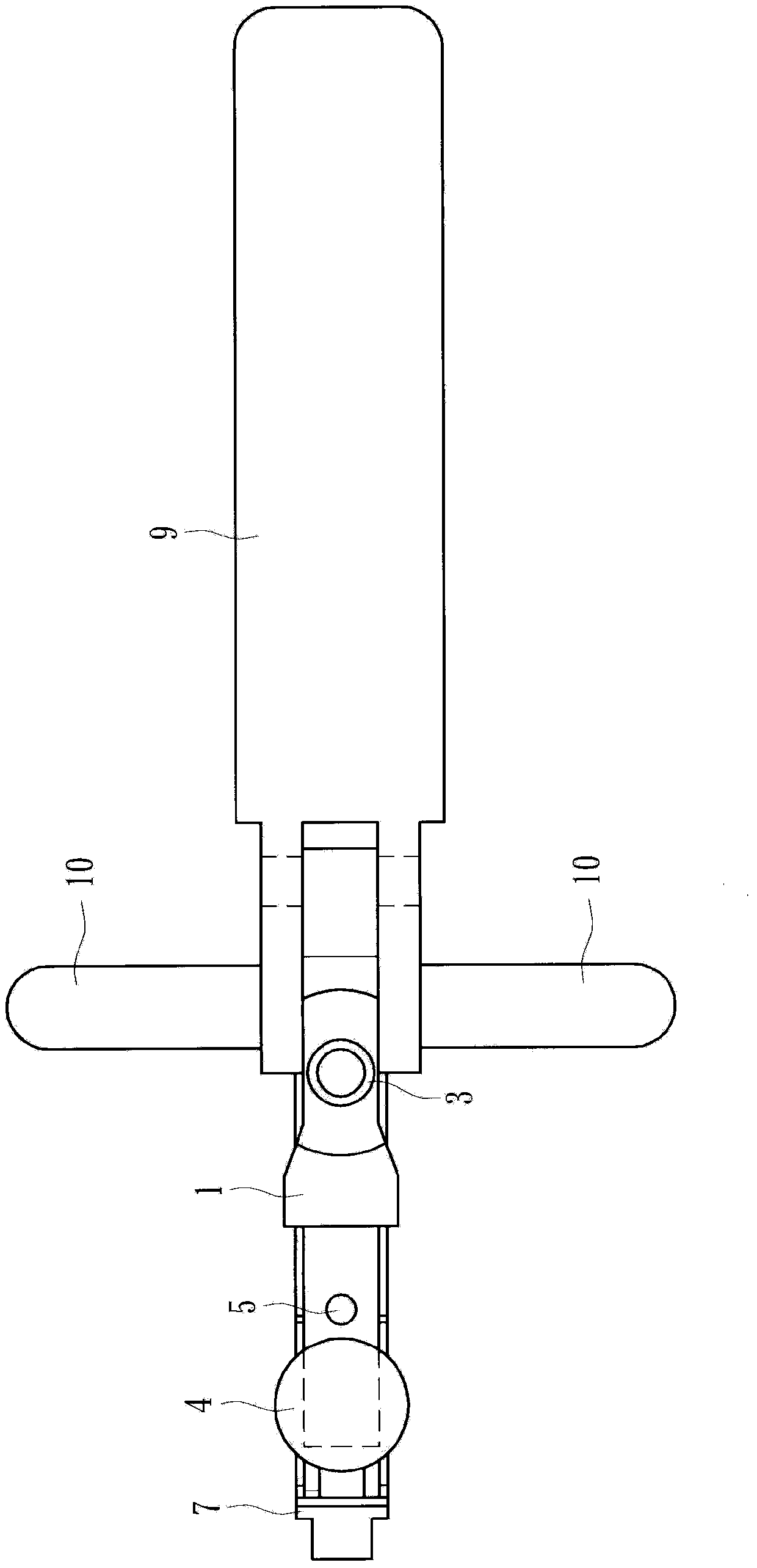

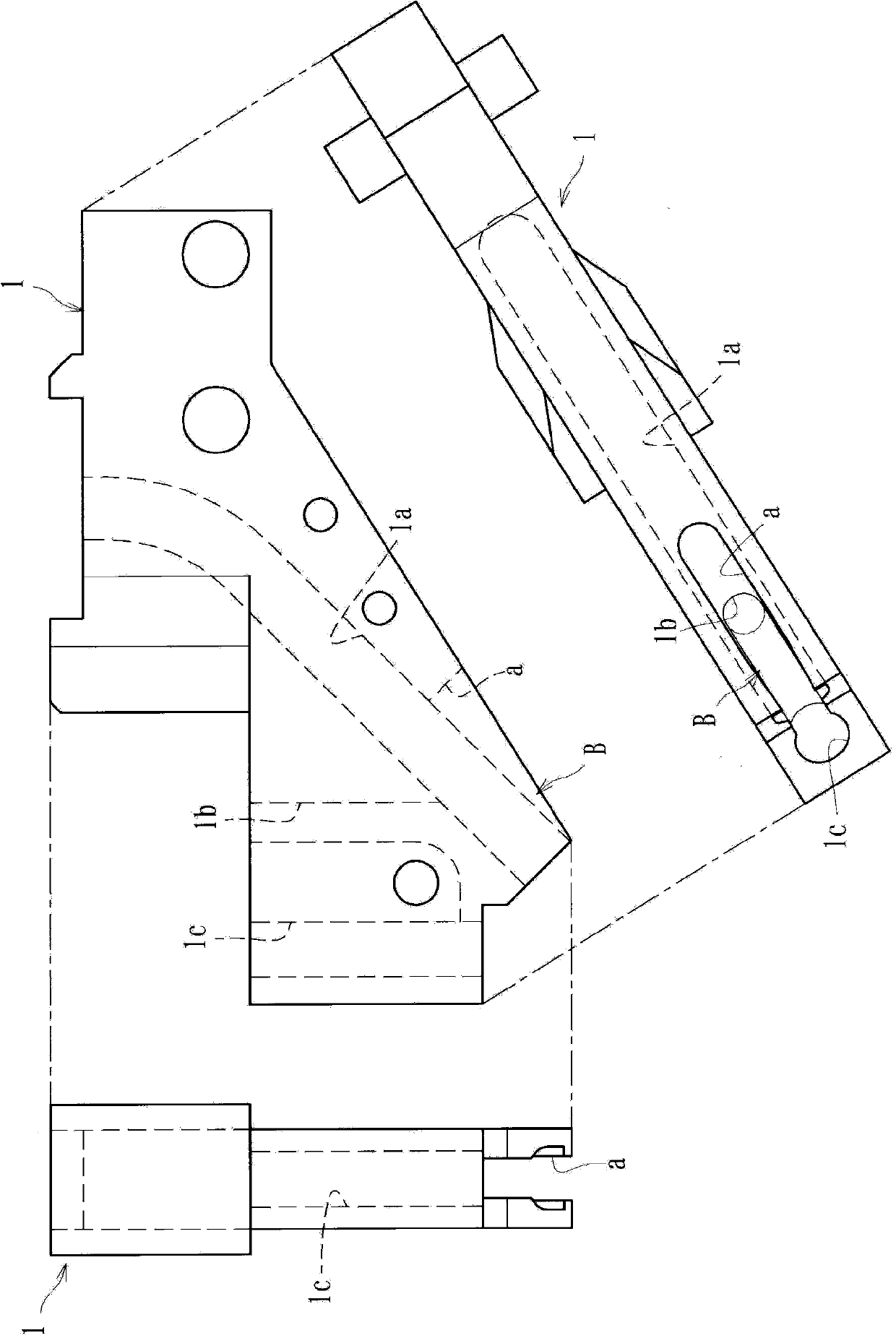

[0033] The rivet setter of the present invention is intended to assemble rivets sequentially supplied from a rivet supply device by inserting rivets into holes formed in workpieces, and mainly includes such as Figures 1 to 5 Shown are a main body 1 , a mounting member 2 , an operation button 4 , a pressing member 7 , and a detection sensor 8 .

[0034] In the illustrated embodiment, a torque damper device (lock-up clutch device) W as an example of a workpiece to which a rivet R is assembled is in Figure 13 is shown in . If the rivet R is assembled and punched, any other workpiece can be used. The torque damper device W is used to connect the torque converter case and the turbine, and includes a main body Wa holding a plurality of damper springs Wr at its outer periphery, and a pressing plate D for pressing the damper springs Wr.

[0035] Furthermore, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com