Device for supplying fluid to a continuously variable transmission

A continuously variable transmission, transmission technology, applied in mechanical equipment, components with teeth, transmissions, etc., can solve problems such as energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

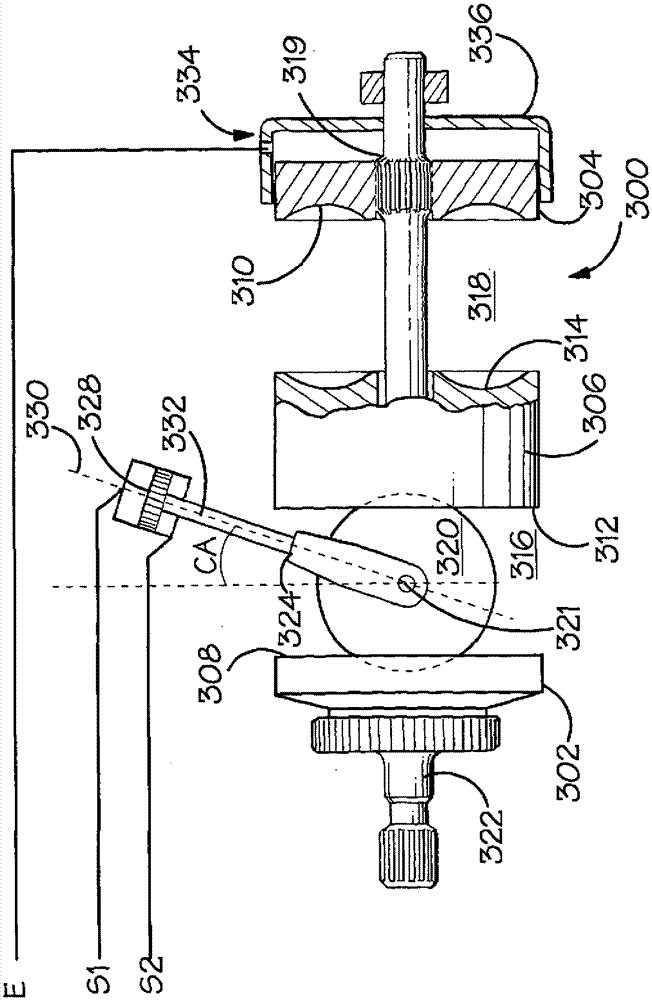

[0029] figure 1 The converter 300 represented in is known in the art and is given here for completeness and because its mode of operation creates some technical challenges addressed by the present invention. Note however that this is given by way of example and not limitation. The invention can be implemented in transmissions employing other types of variators. The variator 300 is a toroidal race rolling traction type with coaxially mounted input races 302 , 304 on either side of a central output race 306 . The face 308 , 310 of each input race is semi-annularly recessed and directed towards a similarly recessed face 312 , 314 of the output race respectively, thereby defining two generally annular cavities 316 , 318 accommodating the drum 320 . Only one roller is shown, but actual transducers typically have two or three such rollers spaced at circumferential intervals around each cavity 316 , 318 . The races are mounted on the variator shaft 322 to which the input races 302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com