Dyeing and finishing process of pantyhose fabric

A processing technology, pantyhose technology, applied in pantyhose, fabric surface trimming, socks, etc., can solve problems affecting product quality and wearability, etc., to eliminate dyeing steam, meet wearing needs, and have a pure and flawless appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

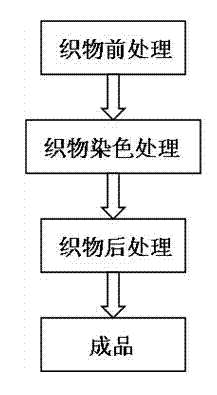

Image

Examples

Embodiment 1

[0018] The specific implementation steps are as follows:

[0019] a) Fabric pretreatment, the fabric pretreatment process includes: presetting, preshrinking and pretreatment; among them, presetting adopts dry presetting, the setting temperature is 95 ℃, and the setting time is 20s; when preshrinking, first 0.095Mpa vacuum 7min, then pre-shrink for 20min, the pre-shrink temperature is 105°C, and then vacuumize at 0.095Mpa for 7min;

[0020] Since the fabric is pre-formed first, and then pre-shrunk at high temperature, and the pre-shrinking temperature is higher than the pre-setting temperature, the problem of dyeing stains is better solved, even if the pre-setting causes fabric steam spots, so that steam spots appear The local crystallinity of the fiber is different, but it can still tend to be balanced and unified under the higher temperature conditions of subsequent pre-shrinking and the pre-shrinking vacuum for a longer period of time. When dyeing, the dye uptake rate of eac...

Embodiment 2

[0024] The specific implementation steps are as follows:

[0025] a) Fabric pre-treatment, the fabric pre-treatment process includes: pre-setting, pre-shrinking and pre-treatment; among them, pre-setting adopts dry pre-setting, the setting temperature is 96 ℃, and the setting time is 22s; when pre-shrinking, 0.095Mpa vacuum first 8 minutes, then pre-shrink for 25 minutes, the pre-shrinking temperature is 107 ° C, and then vacuumize at 0.095Mpa for 8 minutes;

[0026] Since the fabric is pre-formed first, and then pre-shrunk at high temperature, and the pre-shrinking temperature is higher than the pre-setting temperature, the problem of dyeing stains is better solved, even if the pre-setting causes fabric steam spots, so that steam spots appear The local crystallinity of the fiber is different, but it can still tend to be balanced and unified under the higher temperature conditions of subsequent pre-shrinking and the pre-shrinking vacuum for a longer period of time. When dyeing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com