High-efficiency dynamic and static separator

A technology of dynamic and static powder separators, which is applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc. It can solve the problems of poor classification accuracy and large particle range, and achieve high powder selection efficiency , small particle size range, and easy material particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

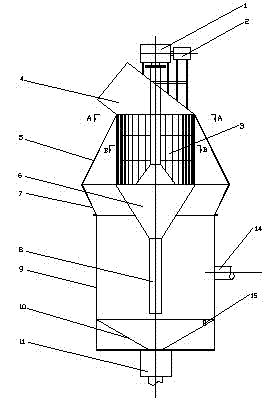

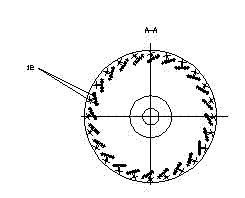

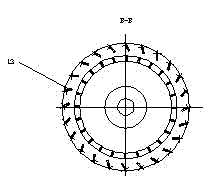

[0016] As shown in the drawings, the motor 1 drives the reducer 2 to run, and the rotor 3 connected to the output shaft of the reducer 2 rotates at the same time. The dust-laden compressed gas enters from the feed pipe 14 and consists of the bottom shell 9 of the separator, the lower shell 7 of the separator, the upper shell 5 of the separator, the guide vanes 13 located in the upper shell 5 of the separator, and the rotor of the separator. The dynamic and static powder concentrator composed of The material pipe 8 is collected into the discharge hopper 10 in the bottom passing through the body. The lower part of the discharge hopper 10 is installed with an electric arc valve 11, and the upper part of the discharge hopper is installed with a material level gauge 15. When the coarse material powder in the discharge hopper 15 reaches a certain amount, the material level meter sends a signal command, the valve plate of the electric arc valve 11 is opened, and the coarse material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com