Bidirectional pushing and pressing expansion type barrel inside cleaner

A washer and inflatable technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of many people, slow speed, unsafe, etc., and achieve the effect of solving the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

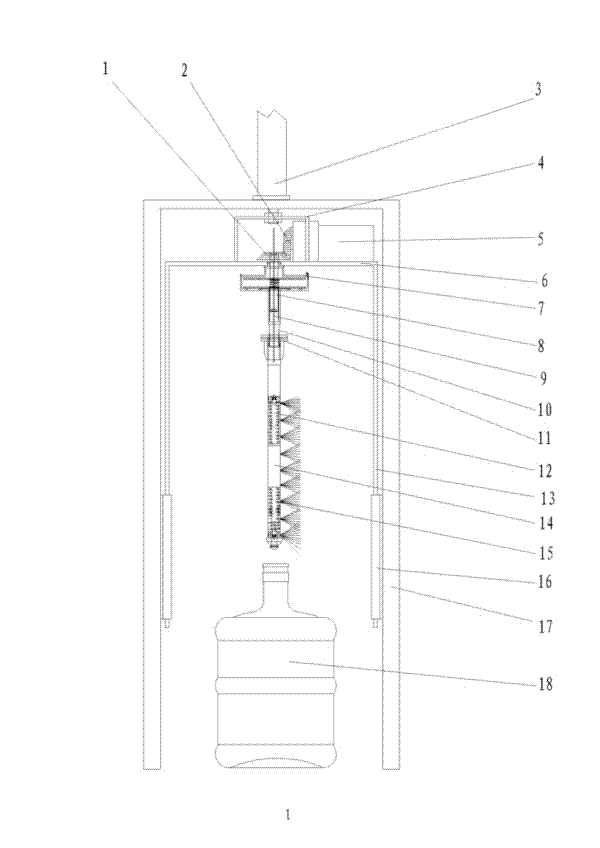

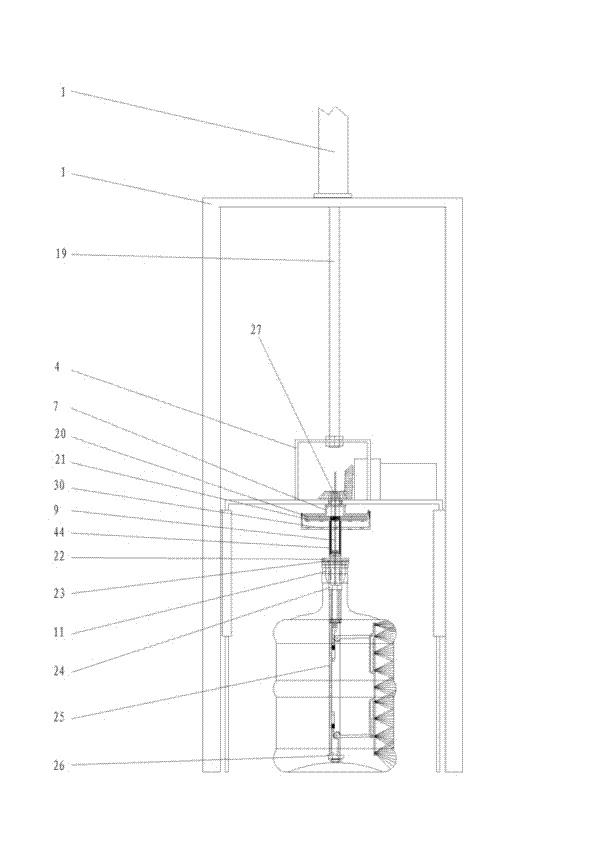

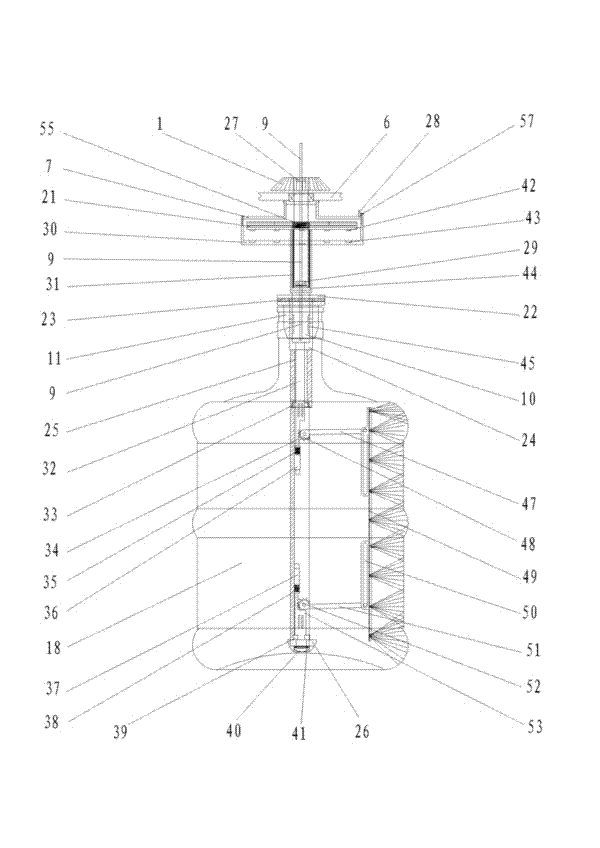

[0011] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , two-way pushing and expanding barrel cleaning device, characterized in that the cylinder (3) is installed on the bracket (17), guide pipes (16) are installed on both sides of the bracket (17), and the motor ( 5), the connecting frame (4), the two sides are connected with the guide shaft (13), the driving wheel (2) is installed on the motor (5), and is geared together with the driven wheel (1), the upper end of the driving shaft (8) The middle end of the driven wheel (1) is connected with the circular friction plate (20), the upper end of the clutch sleeve (44) is connected with the clutch friction plate (21), and the lower end is connected with the guide shaft (10). (14) is installed with bucket top brush seat (12) and bucket bottom brush seat (15), the brush shaft (25) upper end is connected with the brush shaft guide pipe (24) that brush shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com