Multi-purpose box dividing modeling leaky-mode machine

A multi-purpose, box-dividing technology, applied in molding machines, casting molding equipment, manufacturing tools, etc., can solve problems such as difficult to guarantee product quality, complexity, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

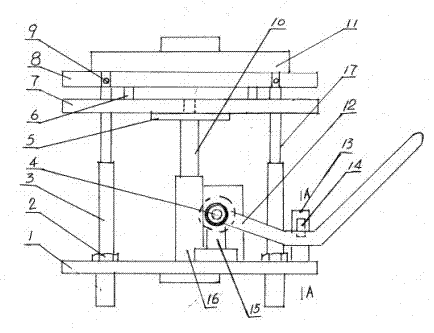

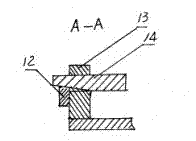

[0008] Such as figure 1 , 2 As shown, the present invention comprises a machine base 1, a column, a lifting mechanism, a sand box 11, a template 7 and a frame plate 8, and is characterized in that; the base is provided with four column guide shafts 3, and one end of the column guide shaft passes through a nut 2. It is locked and fixedly connected with the base, and the other end is socketed with the carbon steel column 17. The upper end of the carbon steel column passes through the column hole provided on the form plate and is fixedly connected with the formwork plate 8 through the locking stud 9. The lower end of the column is connected with the frame plate 8. The base is fixedly connected, and a lifting mechanism is fixedly connected to the middle part of the base. The lifting mechanism includes two bearing blocks 15 fixedly connected to the base. One end is fixedly connected with one end of a spoon-shaped handle 12, and the base adjacent to the bearing seat is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com