Boring fixture for rear lug of HSG series engineering cylinder

An engineering and series technology, applied in the field of boring processing of back earrings, can solve problems such as increased cost of hydraulic cylinders, out-of-tolerance verticality between holes and threads, delayed delivery, etc., to shorten processing time, improve processing accuracy, Canonical Serialization Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

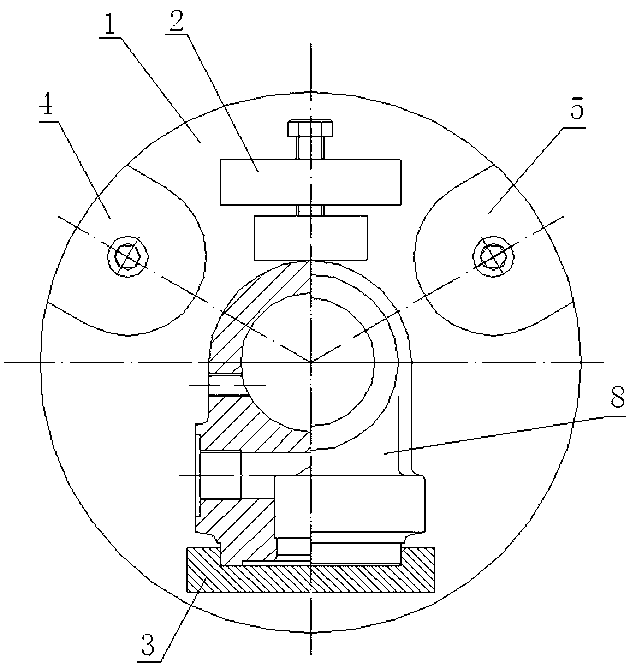

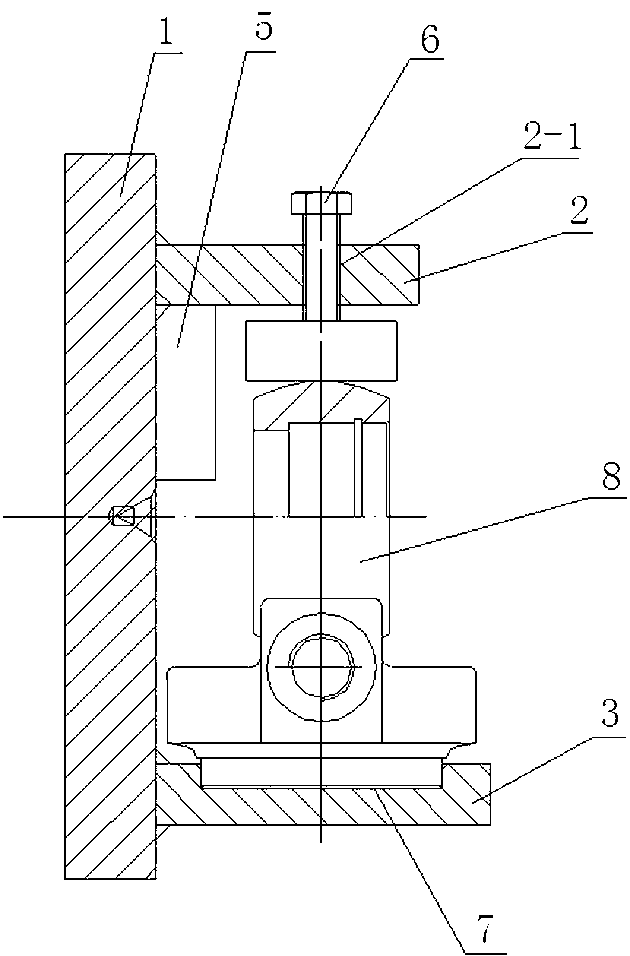

[0009] Such as figure 1 , 2 As shown, in the present invention, a fixed vertical plate 2 and a supporting plate 3 parallel to each other are vertically fixed on the same side of a circular chassis 1. Weight balance weights 4 and 5 are symmetrically connected to the circular chassis 2 on both sides of the fixed vertical plate 3.

[0010] A threaded hole 2-1 is opened on the fixed vertical plate 2, and the axial direction of the threaded hole 2-1 is parallel to the large surface of the circular chassis 1, and the clamping bolt 6 is threaded in the threaded hole 2-1, facing the pallet 3 The side surface of the fixed vertical plate 2 is provided with a workpiece installation groove 7.

[0011] One end of the workpiece 8 is limited in the workpiece installation groove 7, and the other end is positioned by the clamping bolt 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com