Manufacture method of multi-layer gluing bentwood chair and bentwood foot blank pressing machine

A manufacturing method and multi-layer glue technology are applied to the press machine for processing bentwood legs and the field of manufacturing multi-layer glued bentwood chairs, which can solve the problems of complex processing, low production efficiency, and increased production costs, and achieve The effect of high wood utilization rate, smooth lines and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

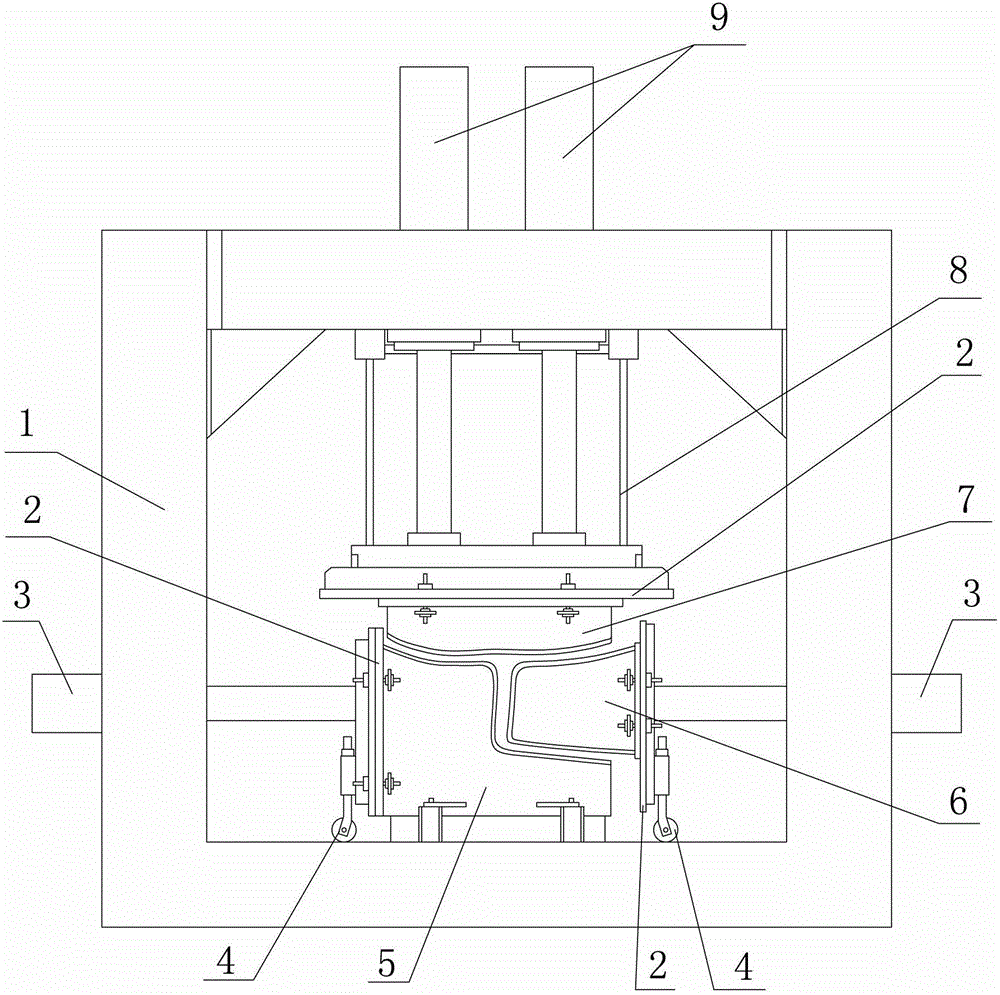

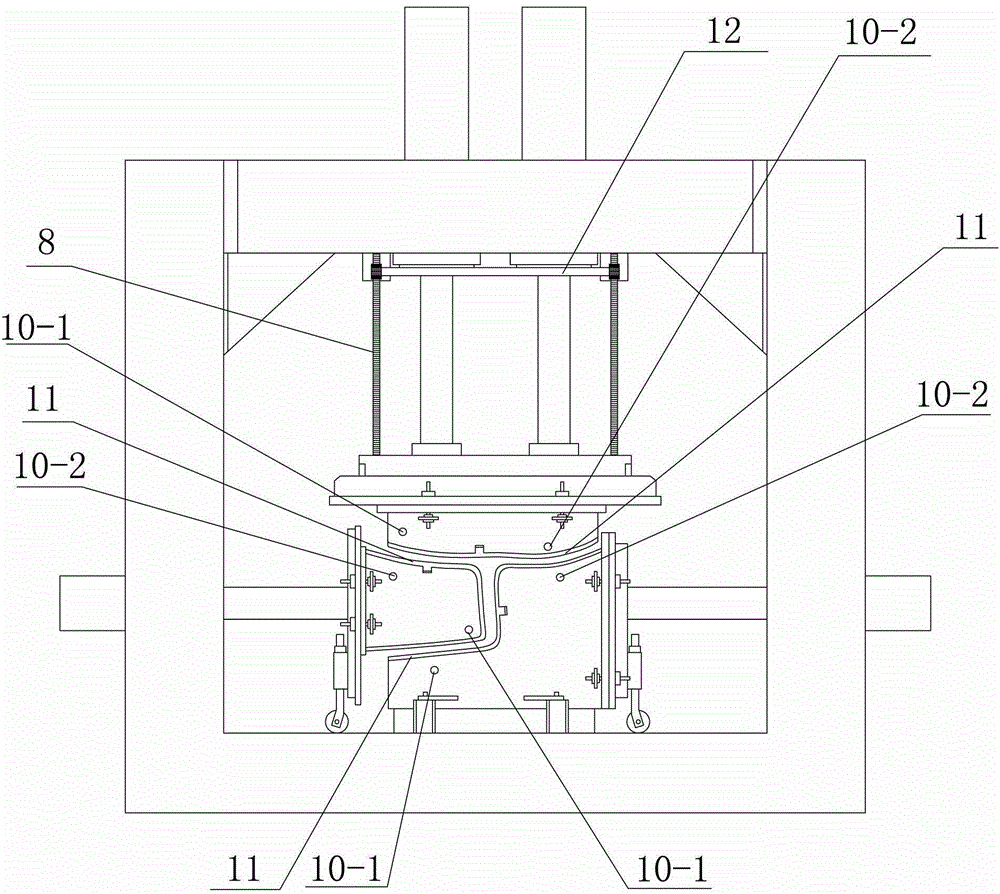

[0078] Example 1, such as figure 1 , figure 2 As shown, in this bent wood base blank press machine, the front chair leg and rear chair leg of the bent wood base base are arranged to the right, the backrest is arranged to the left, and the backrest and rear chair leg are located on the upper side of the front chair leg.

[0079] For the convenience of processing, the left mold can be fixed, while the right mold and upper mold are movable. During processing, place the two wood chip groups at an angle of 45 degrees on the right side of the left mold (the first wood chip group 14-1, the second wood chip group 14-2), then start the right mold to pre-press, and then place the two wood chip groups without The compressed parts are separated and pre-fixed on the left mold and the right mold respectively; then another wood chip group (the third wood chip group 14-3) is put in and the upper mold is started for pre-compression, and then the three wood chip groups bordered Put the wood...

Embodiment 2

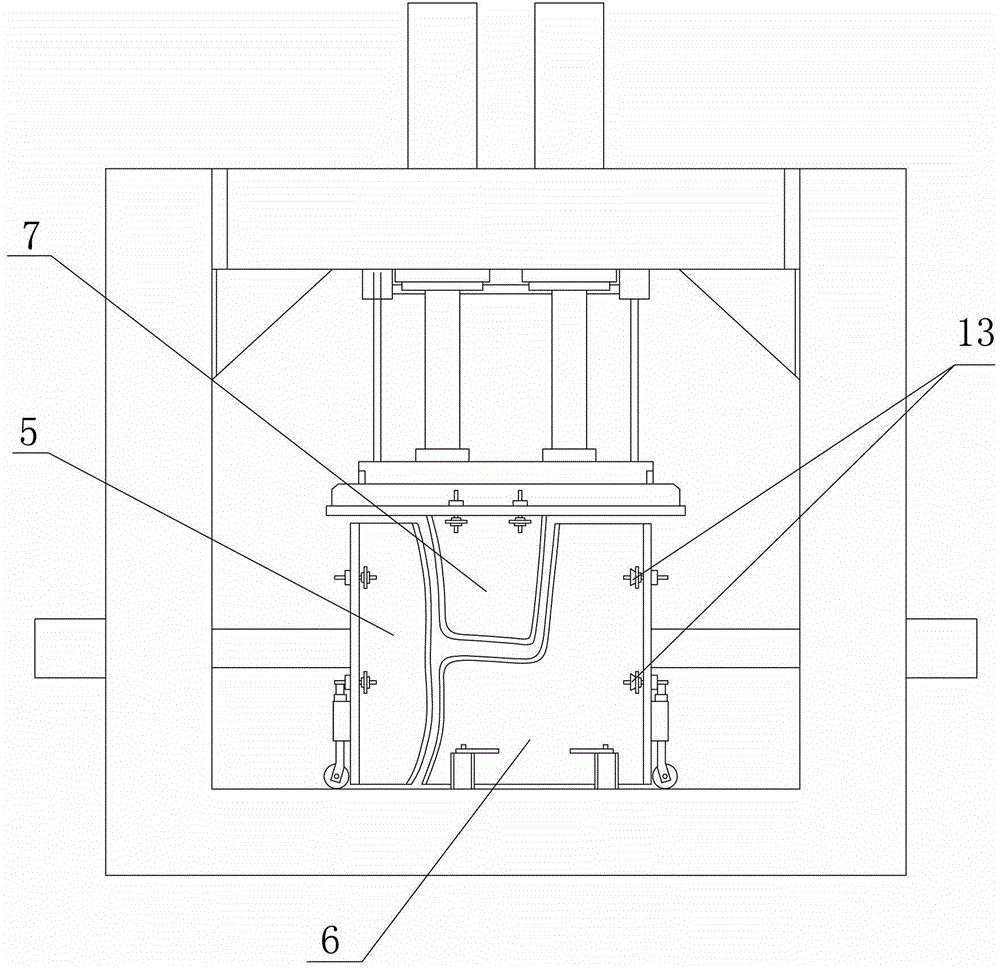

[0080] Example 2, such as image 3 As shown, in this bent wood base blank press machine, the front chair legs and rear chair legs of the bent wood base base are arranged upwards, the backrest is arranged downwards, and the backrest and rear chair legs are located on the left side of the front chair legs.

[0081] For the convenience of processing, the right mold can be fixed, while the upper and lower molds are movable. The processing method of this embodiment is similar to that of Example 1. First, place the two wood chip groups at an angle of 45 degrees on the left side of the right mold, then press the upper mold down for pre-compression, and then place the uncompressed parts of the left ends of the two wood chip groups Separate and pre-fix on the left mold and the right mold respectively; then put another wood chip group from the left side, start the left mold at the same time to pre-press, and then put the wooden triangle in the triangle space where the three wood chip gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com