Unfolding high-voltage test car for electrical equipment

A technology for power equipment and high-voltage testing, which is applied to motor vehicles, vehicle parts, and goods transport vehicles, etc., can solve the problems of handling and testing equipment, troublesome instruments, time-consuming and laborious handling, and heavy testing equipment, saving test preparation time, and reducing cost. Simple and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

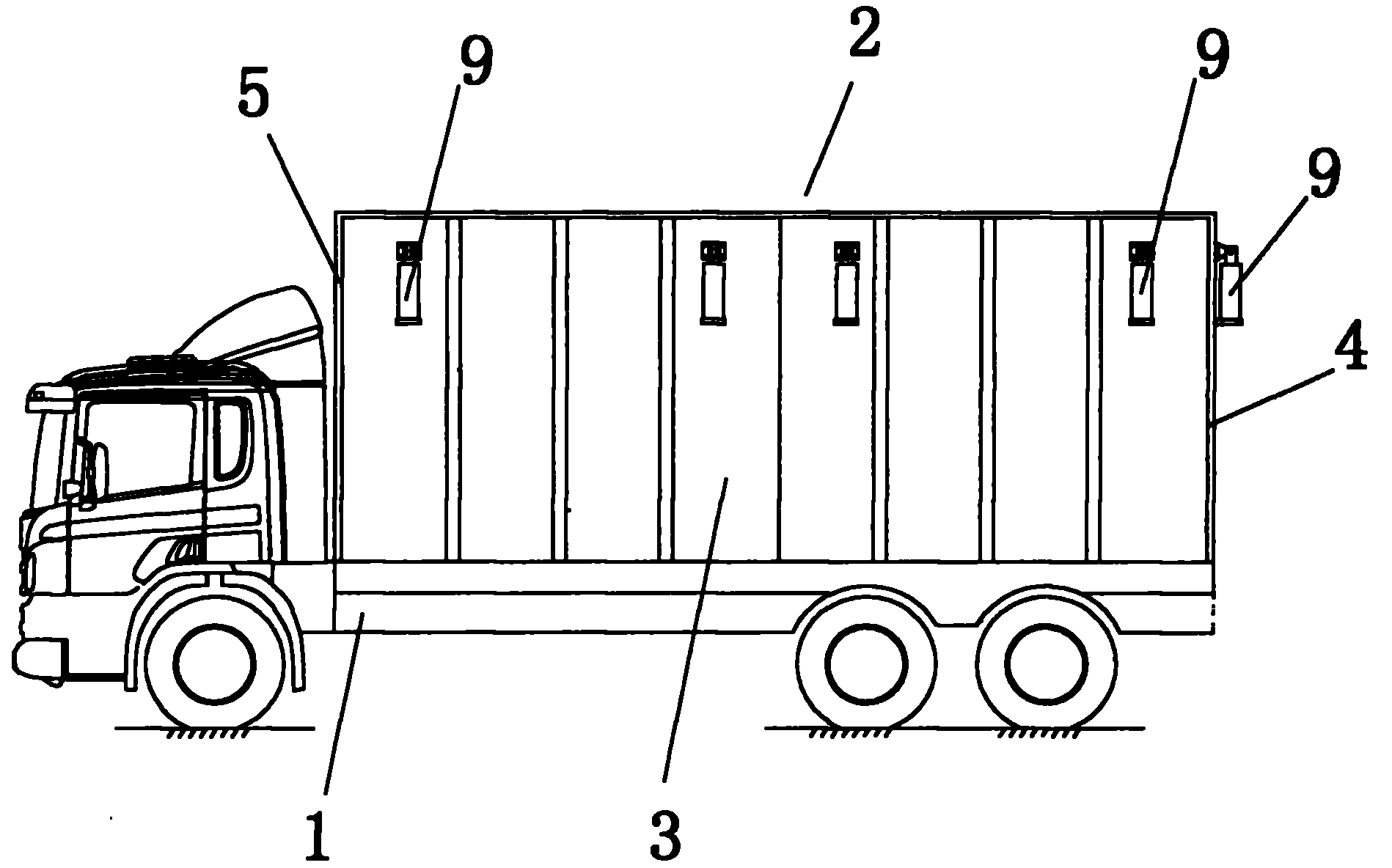

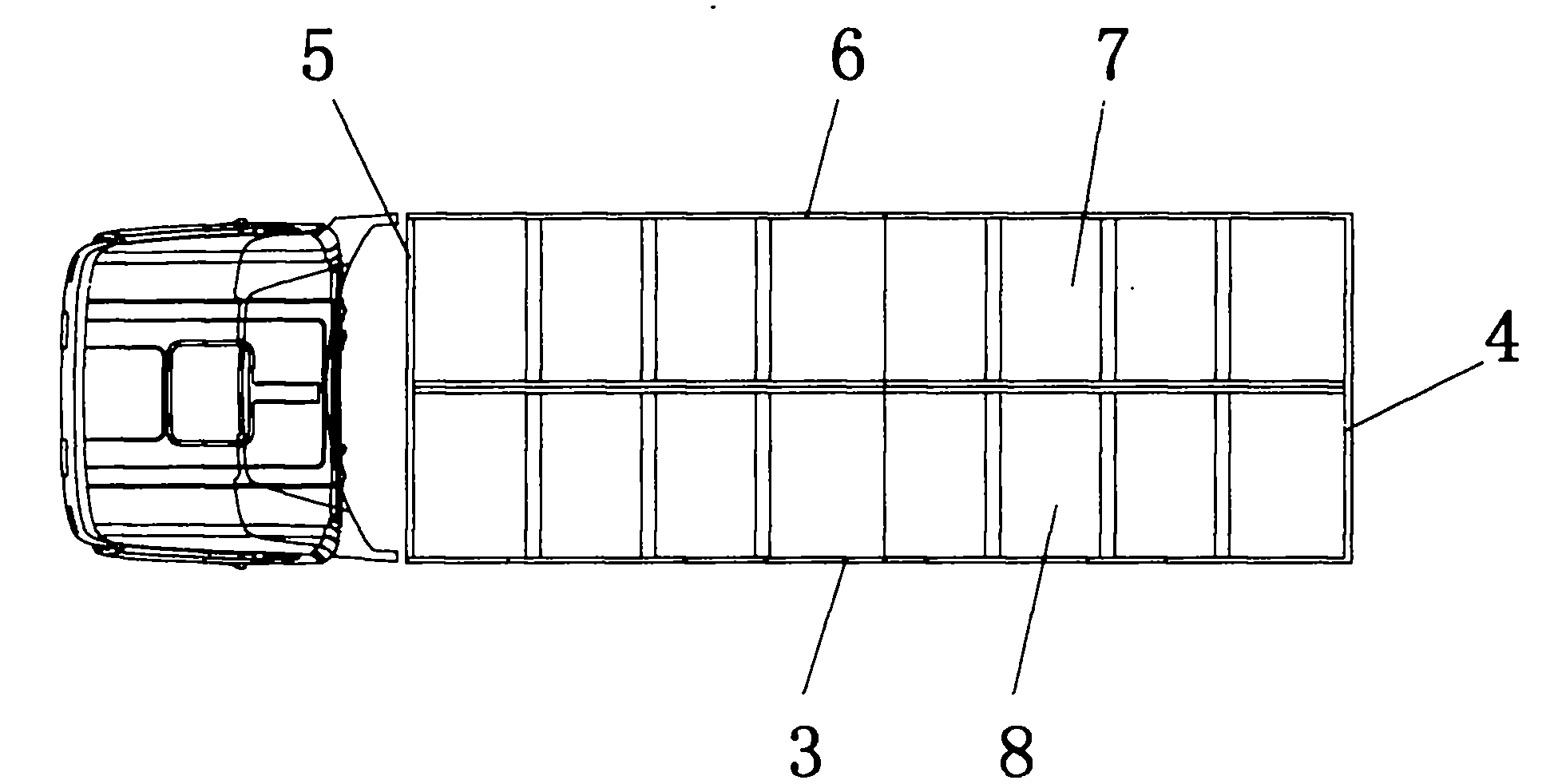

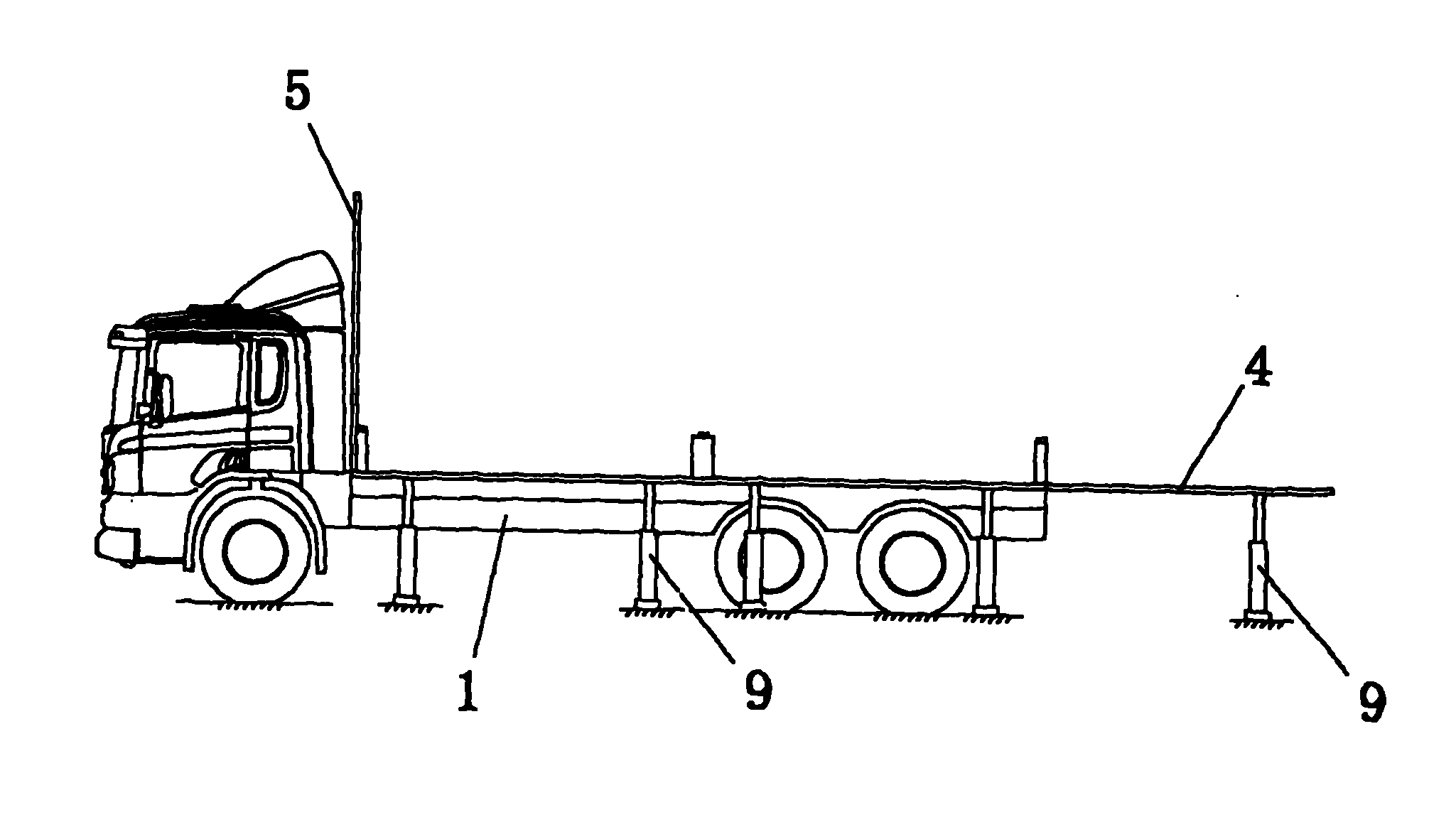

[0013] attached figure 1 It is a kind of unfolded high-voltage test vehicle for power equipment according to the present invention, which includes a car body 1 and a compartment 2; the compartment 2 is arranged on the car body 1; the compartment 2 can be expanded; the compartment 2 includes a first Side plate 3, second side plate 4, front plate 5, tail plate 6, first top plate 7, second top plate 8, hydraulic support feet 9, hydraulic cylinder 10; The lower end of the first side plate 3 is hinged on the car body 1 through a hinge 11; the second top plate 8 is hinged on the upper end of the first side plate 3 through a hinge 11; the second side plate 4 The lower end is hinged on the car body 1 through the hinge 11; the first top plate 7 is hinged on the upper end of the second side plate 4 through the hinge 11; the lower end of the tail plate 6 is hinged on the car b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com