Bearing pedestal for chain-plate head pulleys

A technology of bearing seat and chain plate machine, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of affecting the service life of bearings, high internal bearing temperature, and affecting production, so as to improve the cooling effect and meet the temperature requirements. Control the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

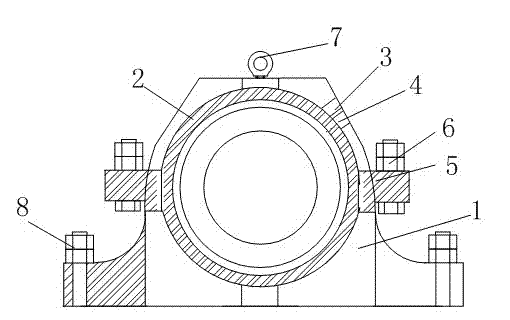

[0015] Such as figure 1 The shown chain plate machine head wheel bearing seat includes a bearing seat body 1, and its special feature is that a cooling water circulation channel 2 is arranged inside the bearing seat body 1 used in the present invention. Specifically, in order to achieve effective circulation of cooling water and improve the cooling effect, a water inlet 3 and a water outlet 4 are provided on the outer side of the bearing housing body 1 , and the water inlet 3 , water outlet 4 and the cooling water circulation channel 2 are connected. Of course, in consideration of the convenience of connection with the water supply assembly and no leakage or abnormal pressure, the water inlet 3 and the water outlet 4 are both provided with independent connection ports.

[0016] As far as a preferred embodiment of the present invention is concerned, considering that synthetic oil can be used as a refrigerant in the cooling water circulation process, the injection requires relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com