A system and method for realizing controllable cooling in the cylinder of a warm isostatic press

A technology of warm isostatic pressing machine and cooling rate, applied in the field of control system, can solve the problems of product quality influence and time affecting product cooling, and achieve the effect of meeting temperature control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

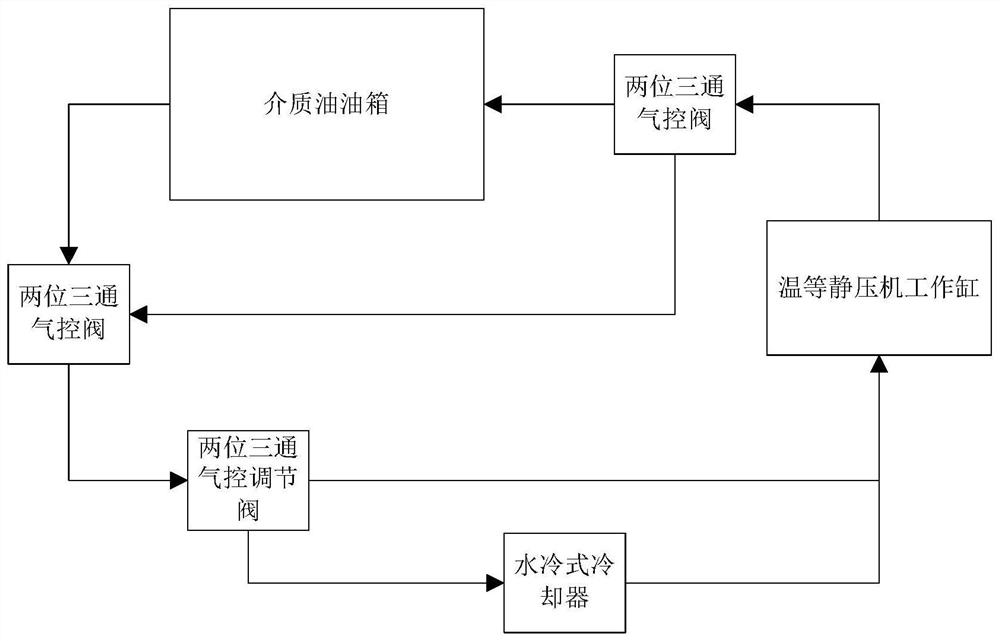

[0022] A system for realizing controllable cooling in a cylinder of a warm isostatic press, comprising a medium oil tank, a first air control valve, a second air control valve, a regulating valve, a working cylinder of a warm isostatic press and a water-cooled cooler. A two-position three-way air control valve is installed on the oil inlet pipeline and oil outlet pipeline of the heating oil tank of the warm isostatic press, and a straight-through circuit is connected between the two two-position three-way air control valves. When two two-position three-way air control valves After all the air sources are connected, the medium oil in the working cylinder of the warm isostatic press does not return to the heating oil tank, but directly returns to the working cylinder. , the medium oil in the working cylinder of the warm isostatic press can return to the heating oil tank, that is, the air source of the two two-position three-way air control valves is only disconnected when the wor...

Embodiment 2

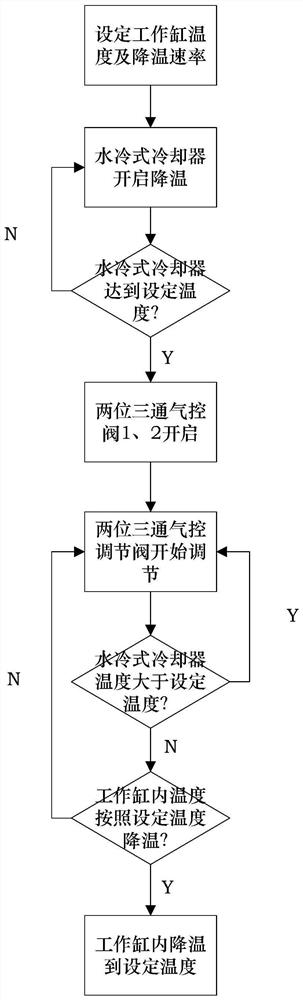

[0024]A control method for realizing the controllable cooling in the cylinder of the thermoisostatic press, specifically: 1) completing the setting of the cooling temperature and the cooling rate of the working cylinder of the thermoisostatic press, and realizing the setting of the cooling in sections, each section Different cooling rates can be set; 2) Turn on the water-cooled cooler to run, and reduce the output temperature of the cooler to the set temperature, and then perform internal self-circulation and maintain the output temperature of the cooler; 3) When the temperature isostatic press After the product is pressed and enters the controllable cooling process of the product in the working cylinder, the system automatically connects the air sources of the two two-position three-way air control valves at the same time to complete the opening of the two-position three-way air control valves, so as to realize the medium oil of the working cylinder. Then return to the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com