Method for righting jacket by using single cantilever gin pole and double hooks

A technology for jackets and poles, which is applied in construction and infrastructure engineering, etc., can solve the problems of increased jacket weight, increased project cost, increased expense and construction period, etc., to reduce installation weight, reduce requirements, and reduce project costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

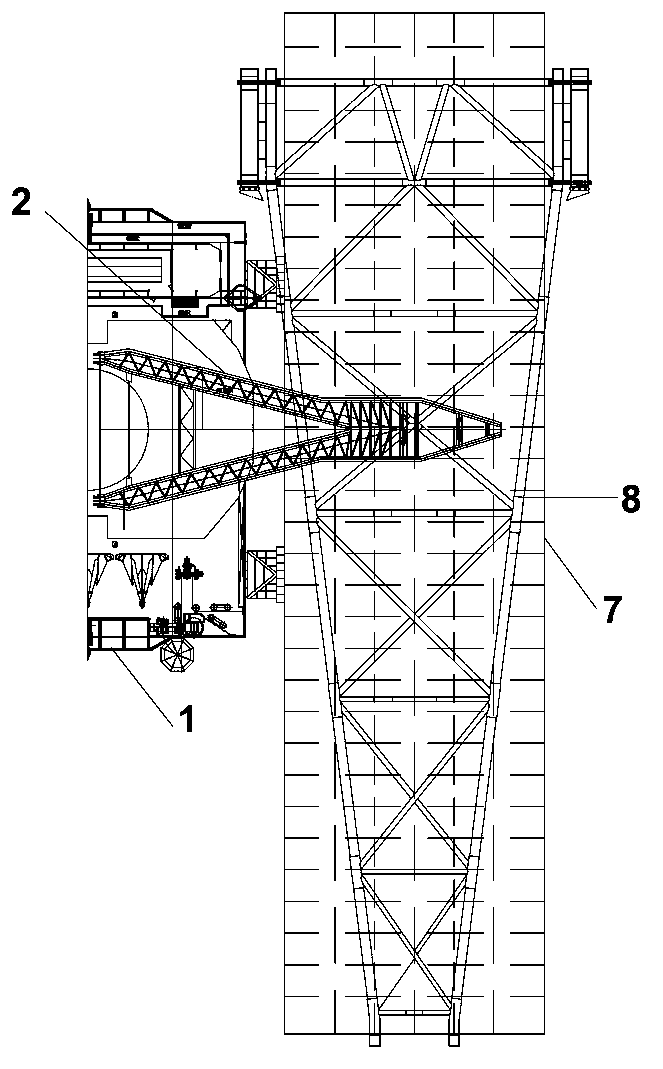

[0036] first step, such as figure 1 As shown: the transport barge 7 leans against the tail of the floating crane 1, and one end of the two hoisting slings 5 is respectively connected to the main hook 3 of the floating crane 1, and the other end is respectively connected to the main lifting point of the jacket 8; One end of the righting rigging 6 is connected with the auxiliary hook 4 of the floating crane 1, and the other end is connected with the righting lifting point of the jacket 8;

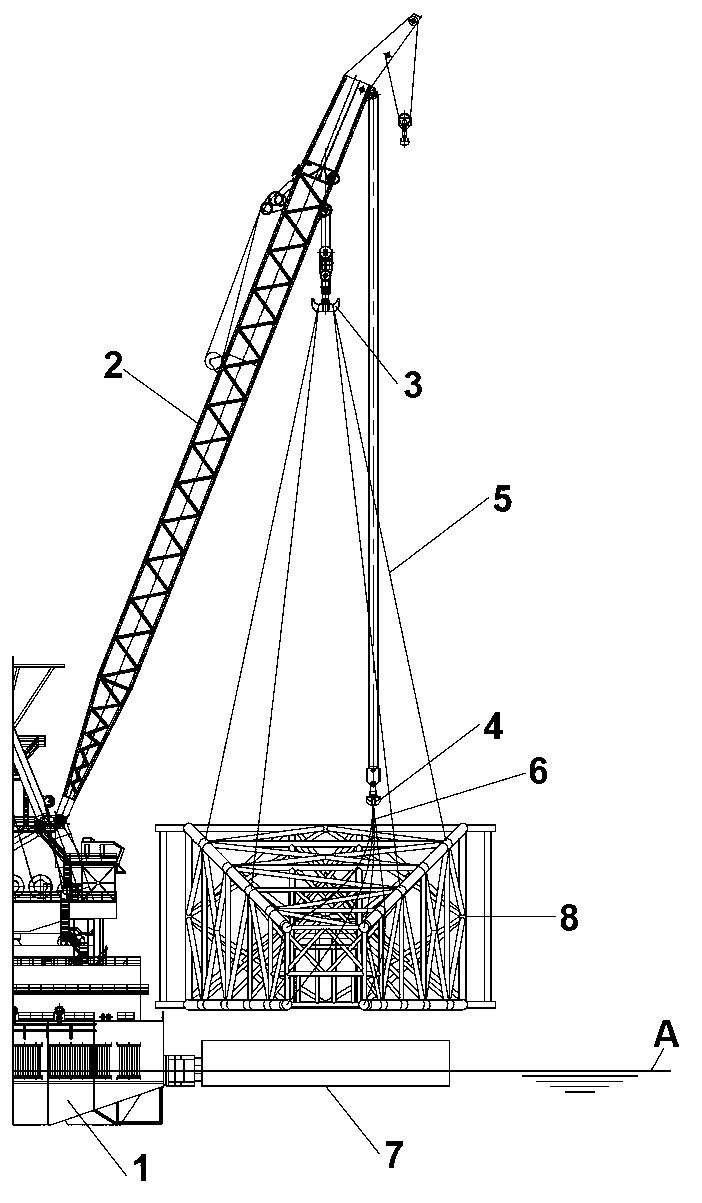

[0037] The second step, such as figure 2 Shown: use the main hook 3 of the floating crane 1 to lift the jacket 8, and drag the transport barge 7 away from the floating crane 1;

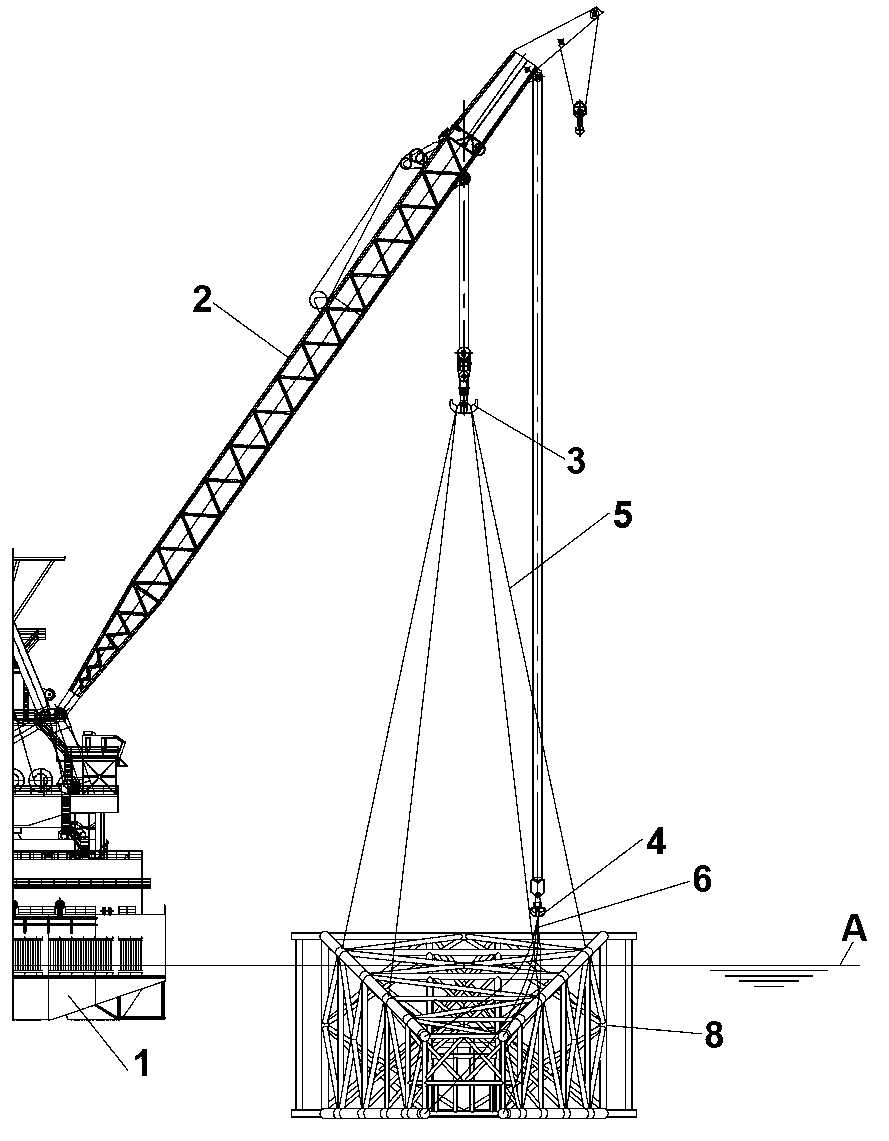

[0038] The third step, such as image 3 Shown: the main hook 3 is lowered, so that the jacket 8 part is submerged in seawater;

[0039] The fourth step, such as Figure 4 , Figure 5 As shown, first lower the floating crane 1 pole 2 to a predetermined angle, and use the tugboat 9 to rotate the jacket 8 to a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com