Drawing snapping line releaser and line drawing method in building construction

A wire pay-off and elastic wire technology, which is applied in construction, building structure, construction material processing and other directions, can solve the problems of long pay-off delay, sour feeling, and wrestling, so as to improve the progress of pay-off and flexible use. Lightweight, accurate and reasonable construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

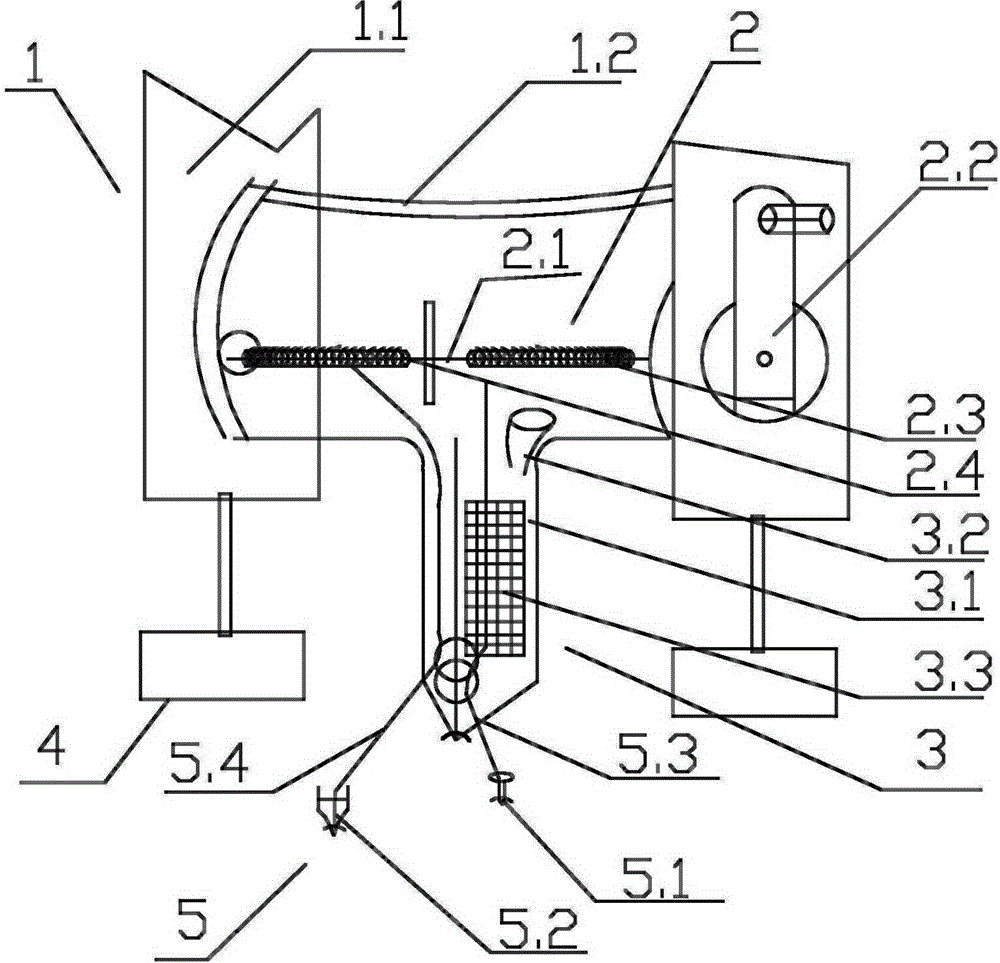

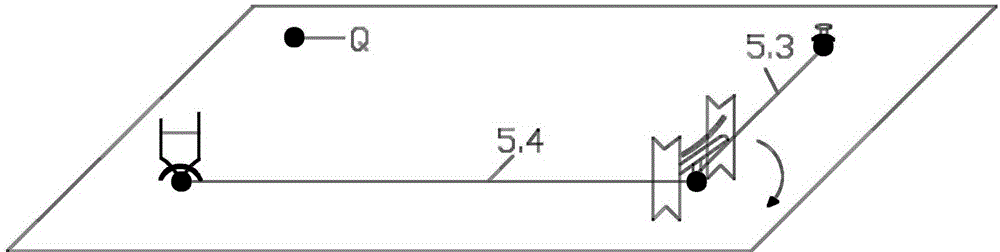

[0019] Combine below figure 1 , figure 2 The present invention is further explained.

[0020] An elastic wire drawing device, which is mainly composed of a wire frame 1, a spool 2, an ink fountain 3, a rubber cup 4, and an elastic wire device 5.

[0021] The wire frame 1 includes an end plate 1.1 and an outer sleeve 1.2; the wire frame end plate 1.1 can be made of thin iron sheet, or can be made of wood, plywood, etc. The selected material should be compatible with the outer sleeve 1.2. Connected as a whole; the end plate has a hole in the middle to form a static fit with the outer diameter of the bearing, the bearing and the spool 2 are in transitional fit, and the bearing is purchased in the market.

[0022] The outer sleeve 1.2 is made of a cylinder with a diameter of 140-160 mm, which can be made of 1 mm thick thin iron sheet, or made of bamboo, wood, or plastic; the front of the outer sleeve is connected to the ink fountain 3, and the two The end is connected with the end pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com