Engine fixing base

A technology of engine and fixing seat, which is applied in the direction of fuel air filter, etc., can solve the problems of insufficient compactness, cumbersome installation, complex structure, etc., and achieve the effect of small air intake resistance, good tightness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

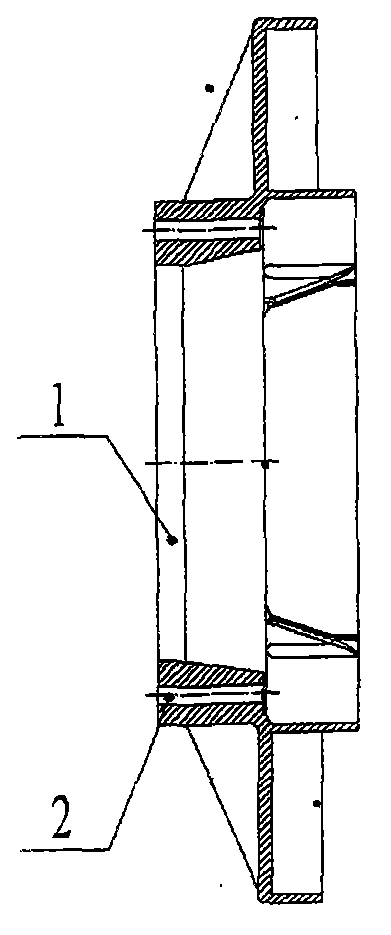

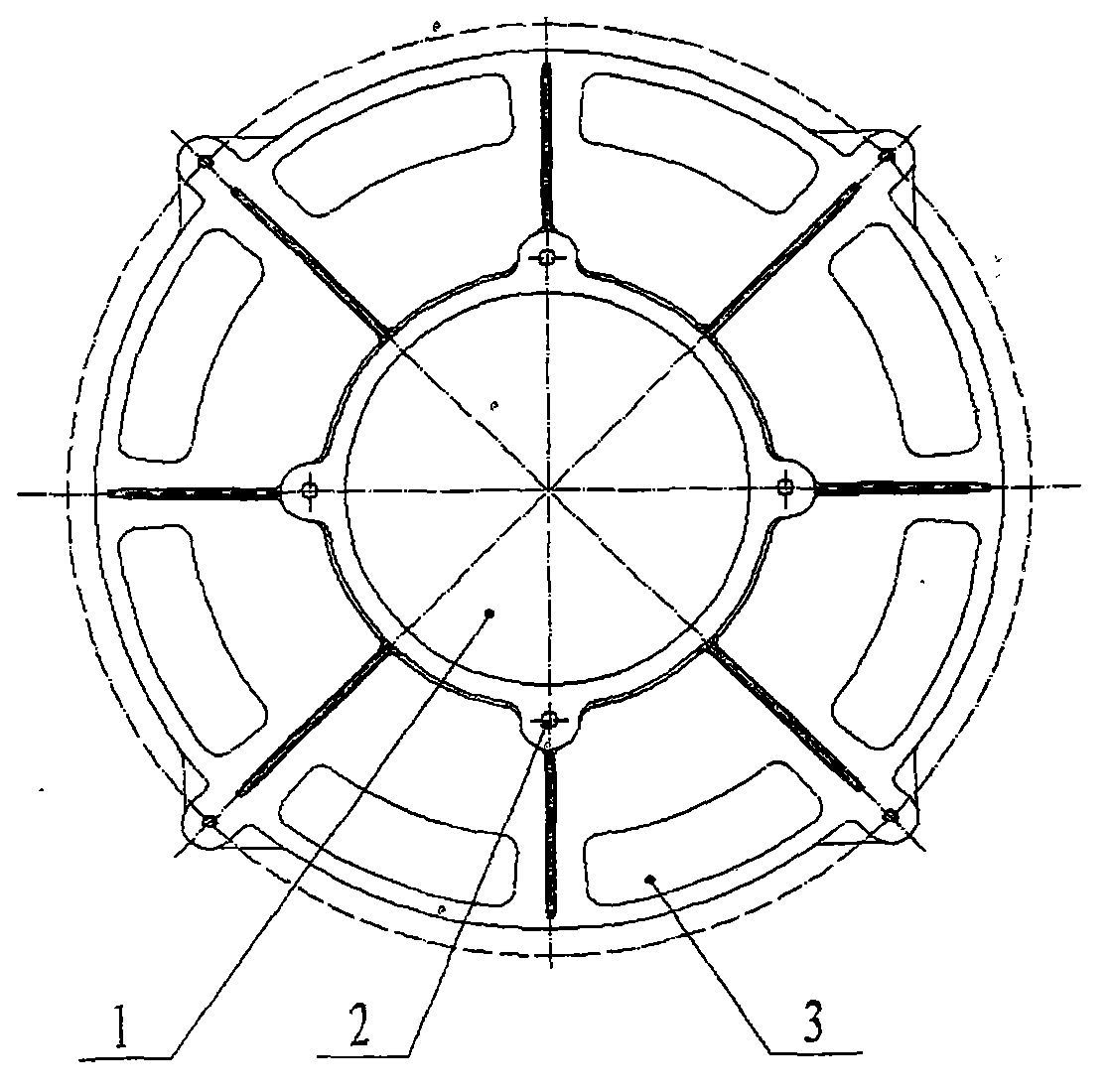

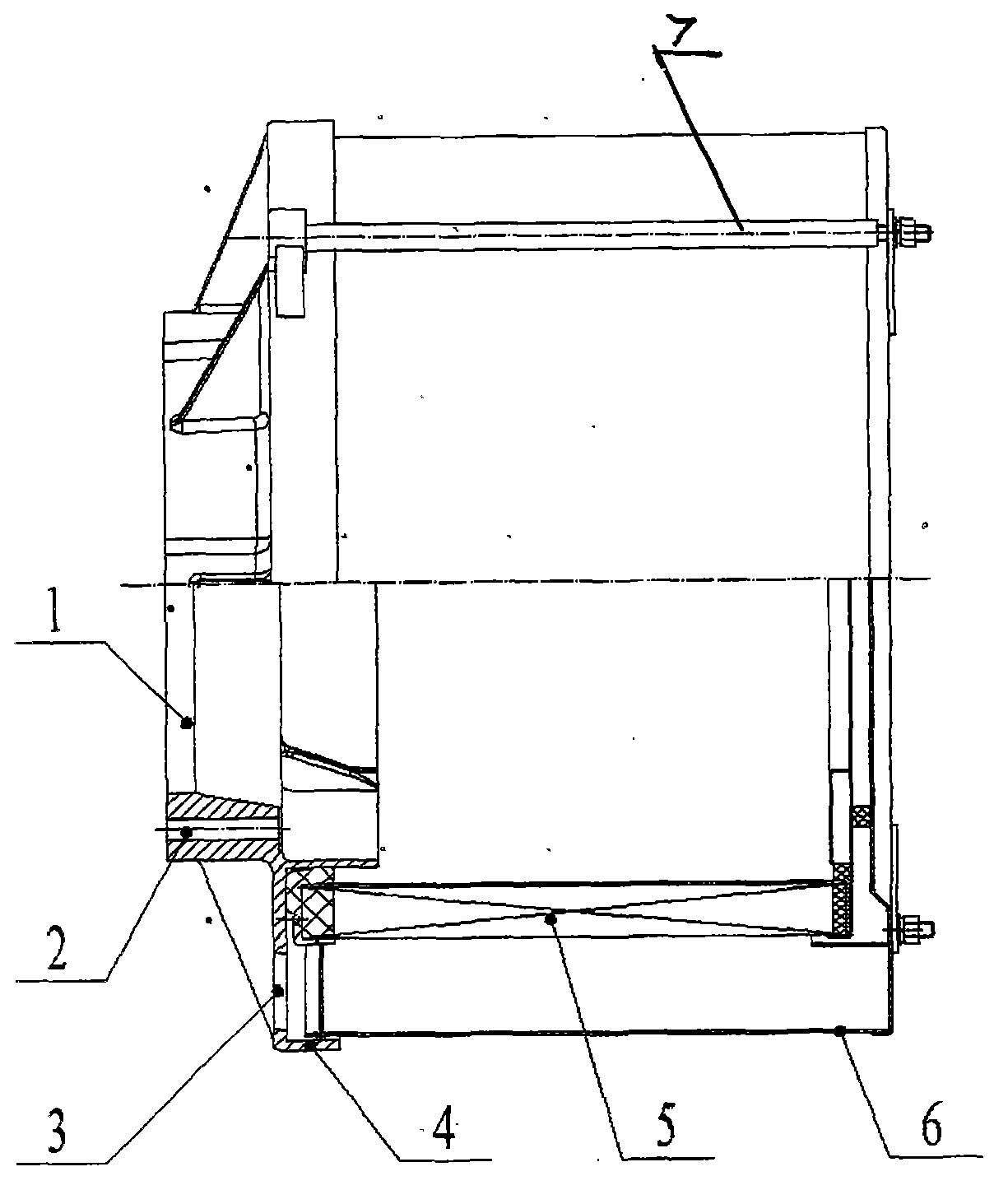

[0014] The best embodiment of the present invention is such that the casing (6) is fixedly mounted on the flange (4) by long bolts (7), and the inner chamber of the casing (6) is equipped with an air filter element (5). Eight air inlets (3) are evenly distributed on the flange (4), and the air inlets (3) communicate with the air outlet (1) through the air filter element (5). Flange (4) has mounting bolt to be connected and fastened with engine by bolt mounting hole (2). A flange (4) integrating air intake and air outlet, and the installation of the air filter is also completed by the flange (4). The flange (4) is a casting and includes an air inlet (3) and bolt mounting holes (2). The flange is a casting and includes an air inlet (3), an air outlet (1) and bolt mounting holes (2). During installation, it is fixed on the engine through the bolt installation holes (2), avoiding the cumbersome work of adding installation brackets. When the air filter is working, the air enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com