Supercharged engine intake manifold for integrated intercooler

A supercharged engine and intake manifold technology, which is applied in the direction of machines/engines, engine components, combustion engines, etc., can solve the problem of insufficient utilization of the heat exchange area of the intercooler, unreasonable design of the intake manifold diversion, and shortened The service life of the intake manifold and other issues can be improved to improve the cooling effect, benefit the stability and improve the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

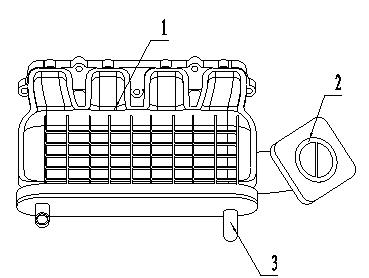

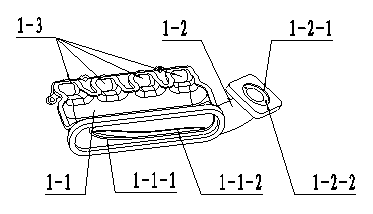

[0021] See Figure 1, figure 2 , the present invention includes an intake manifold body 1, a metal bush 2 and an intercooler 3, the intake manifold body 1 is provided with an intake manifold 1-2, a plenum chamber 1-1 and an intake branch pipe 1- 3. The rear end of the plenum chamber 1-1 is connected to the intake branch pipe 1-3, the bottom of the plenum chamber 1-1 communicates with the intake manifold 1-2, and the metal bushing 2 is embedded in the intake manifold 1 -2, the intercooler 3 is integrated in the plenum chamber 1-1.

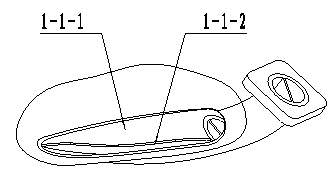

[0022] see figure 2 , image 3 , Figure 4 , the bottom surface of the plenum chamber 1-1 of the present invention is provided with an air intake guide groove 1-1-1 connected to the intake manifold 1-2, and a vertical deflector is arranged in the air intake guide groove 1-1-1 1-1-2, the top surface of the vertical deflector 1-1-2 is an arc-shaped space surface, and the number of arcs matching the number of engine cylinders is provided at the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com