Method for detecting residual stress for high-molecular injection molding processing

A technology of residual stress and injection molding, which is applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of large measurement errors, changes in stress distribution state, and limited types of measurement materials, so as to reduce human interference and achieve high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

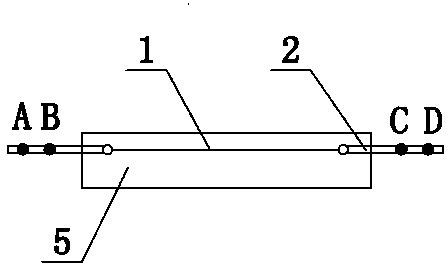

[0064] In this embodiment, the residual stress of the polypropylene injection molded part along the injection flow direction is measured. The sample 5 of the injection molded part has a length of 180mm, a width of 40mm, and a thickness of 3mm. The specific measurement steps are as follows:

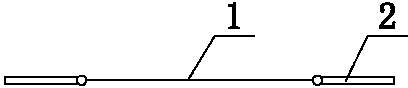

[0065] Step 1: Making the Stress Sensor

[0066]Such as figure 1 As shown, electrode lead-out wires 2 are arranged at both ends of the conductive fiber 1 respectively, and the conductive fiber 1 and the electrode lead-out wires 2 at both ends form a stress sensor, and the conductive fiber 1 adopts the conductive fiber after polyaniline is deposited on the surface;

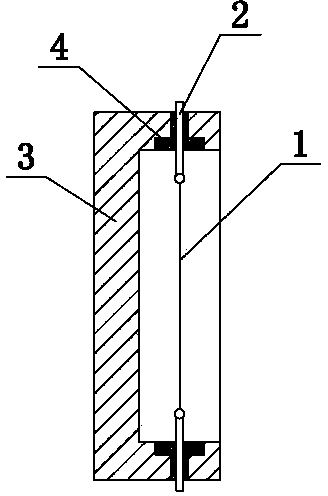

[0067] Step 2: Clamping

[0068] Such as figure 2 As shown, punch a hole on the movable template 3 of the injection mold, then set the rubber sleeve in the hole, pre-install the assembled stress sensor in the movable mold cavity of the injection mold, and connect the electrode lead wire 2 through the rubber sleeve fixed, ...

Embodiment 2

[0099] Repeat Example 1 with the following differences. In this example, the residual stress of the polycarbonate injection molded part is measured, and the glass transition temperature of polycarbonate is 150°C.

[0100] Step 2: Clamping

[0101] The stress sensor is arranged along the length direction of the polycarbonate injection molded part and installed at 0.1mm in the thickness direction of the cavity.

[0102] Step Six: Heat Treatment

[0103] Heat the polycarbonate injection molded parts to 100°C and then anneal for 4 hours,

[0104] The measurement and calculation results are shown in Table 2.

[0105] Table 2: Measurement of fiber resistivity change and residual stress calculation results of six polycarbonate samples

[0106]

[0107] The measurement results show that there is a residual tensile stress in this part of the plastic part, and the average value of the six samples is 7.01MPa.

Embodiment 3

[0109] Repeat Example 2 with the following differences. In this example, the residual stress of the ABS injection molded part is measured, and the glass transition temperature of ABS is 90° C. In the heat treatment, the ABS injection molded part is heated to 100°C, and then annealed for 4 hours.

[0110] Step Eight: Stress Calculation

[0111] Since ABS is an amorphous material whose glass transition temperature is lower than the heat treatment temperature, in order to improve the calculation accuracy, ABS is considered to be in a viscoelastic state, and the corresponding residual stress of polymer injection molded parts is:

[0112]

[0113]

[0114] In the formula,

[0115] , - is the calculated residual stress in the length direction and width direction of the injection molded part;

[0116] - is the elastic modulus of ABS;

[0117] - is the Poisson's ratio of ABS;

[0118] , - is the strain in the length direction and width direction of the ABS inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com