Method for detecting residual stress for high-molecular injection molding processing

A residual stress, injection molding technology, applied in the direction of measuring force, measuring device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

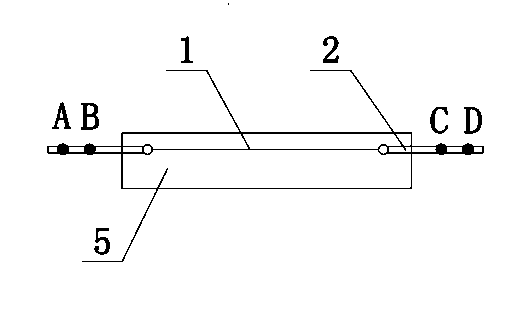

[0066] In this embodiment, the residual stress of the polypropylene injection molded part along the injection flow direction is measured. The sample 5 of the injection molded part has a length of 180mm, a width of 40mm, and a thickness of 3mm. The specific measurement steps are as follows:

[0067] Step 1: Making the Stress Sensor

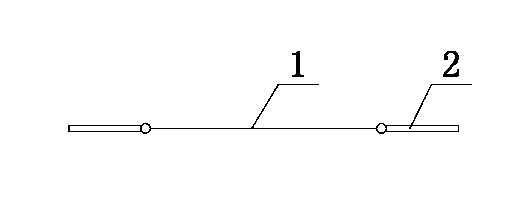

[0068] Such as figure 1As shown, electrode lead wires 2 are arranged at both ends of the conductive fiber 1, and the conductive fiber 1 and the electrode lead wires 2 at both ends constitute a stress sensor. The conductive fiber 1 is a conductive fiber deposited with polyaniline on the surface.

[0069] Step 2: Clamping

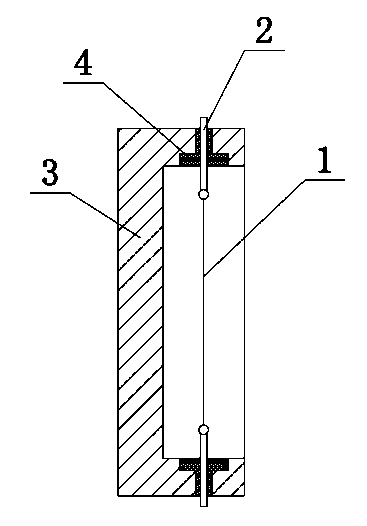

[0070] Such as figure 2 As shown, punch a hole on the movable template 3 of the injection mold, then set the rubber sleeve in the hole, pre-install the assembled stress sensor in the movable mold cavity of the injection mold, and connect the electrode lead wire 2 through the rubber sleeve fixed, thereby fixing the stress sen...

Embodiment 2

[0102] Repeat Example 1 with the following differences. In this example, the residual stress of the polycarbonate injection molded part is measured, and the glass transition temperature of polycarbonate is 150°C.

[0103] Step 2: Clamping

[0104] The stress sensor is arranged along the length direction of the polycarbonate injection molded part and installed at 0.1mm in the thickness direction of the cavity.

[0105] Step Six: Heat Treatment

[0106] Heat the polycarbonate injection molded parts to 100°C and then anneal for 4 hours,

[0107] The measurement and calculation results are shown in Table 2.

[0108] Table 2: Measurement of fiber resistivity change and residual stress calculation results of six polycarbonate samples

[0109] Fiber resistivity before annealing Fiber resistivity after annealing treatment Change rate (%) strain(%) Residual stress (MPa) 3.656 3.608 -1.31 -0.326 6.84 3.666 3.615 -1.39 -0.345 7.24 3....

Embodiment 3

[0112] Repeat Example 2 with the following differences. In this example, the residual stress of the ABS injection molded part is measured, and the glass transition temperature of ABS is 90°C. In the heat treatment, the ABS injection molded part is heated to 100°C, and then annealed for 4 hours.

[0113] Step Eight: Stress Calculation

[0114] Since ABS is an amorphous material whose glass transition temperature is lower than the heat treatment temperature, in order to improve the calculation accuracy, ABS is considered to be in a viscoelastic state, and the corresponding residual stress of polymer injection molded parts is:

[0115]

[0116]

[0117] In the formula,

[0118] - is the calculated stress;

[0119] - is the elastic modulus of ABS;

[0120] - is the Poisson's ratio of ABS;

[0121] , - is the strain in the length direction and width direction of the ABS injection molded part;

[0122] - is the magnitude of creep generated during heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com