Proximity exposure device

An exposure device and proximity technology, which are applied in the direction of photolithography process exposure device, microlithography exposure equipment, etc., can solve the problems of substrate temperature increase, exposure accuracy influence, large temperature difference, etc., to achieve high-precision exposure, inhibit exposure The effect of the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

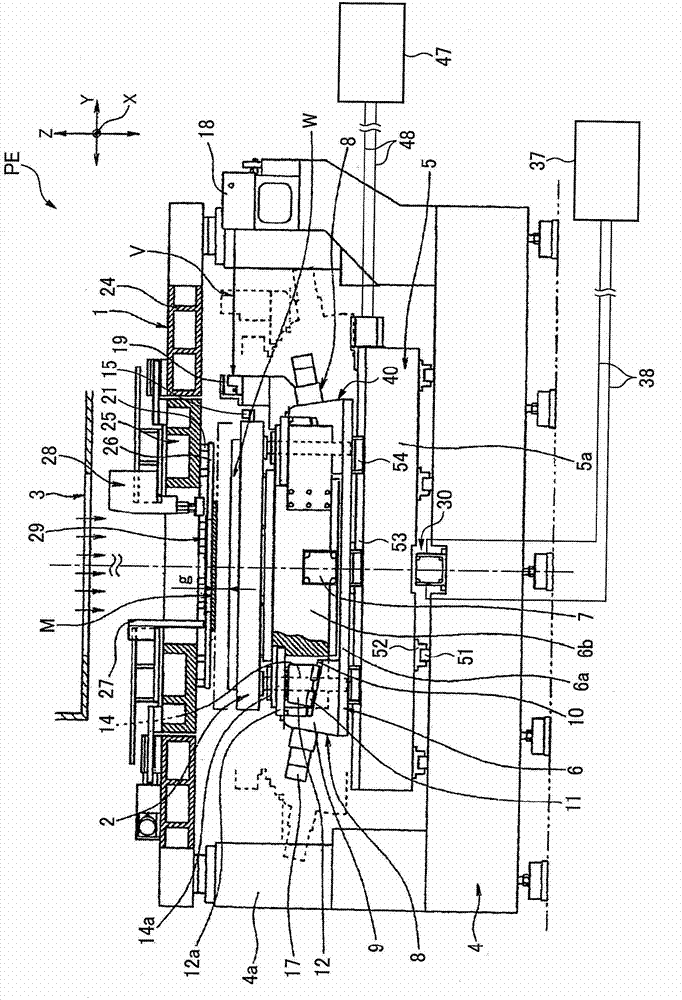

[0112] Hereinafter, the first embodiment of the proximity exposure apparatus of the present invention will be described in detail based on the drawings.

[0113] figure 1 It is a partial cross-sectional front view for explaining the step-by-step exposure apparatus according to the first embodiment of the present invention. Such as figure 1 As shown, the step-and-proximity exposure apparatus PE uses a mask M smaller than the substrate W as the object to be exposed, and holds the mask M with the mask loading table 1, and holds the substrate W with the workbench 2, so that the mask M and The pattern exposure of the mask M is transferred onto the substrate W by irradiating pattern exposure light from the irradiation device 3 to the mask M with the substrates W approaching and facing each other with a predetermined exposure gap. In addition, the stage 2 is moved in two axial steps of the X-axis direction and the Y-axis direction relative to the mask M, and the exposure transfer i...

no. 2 approach

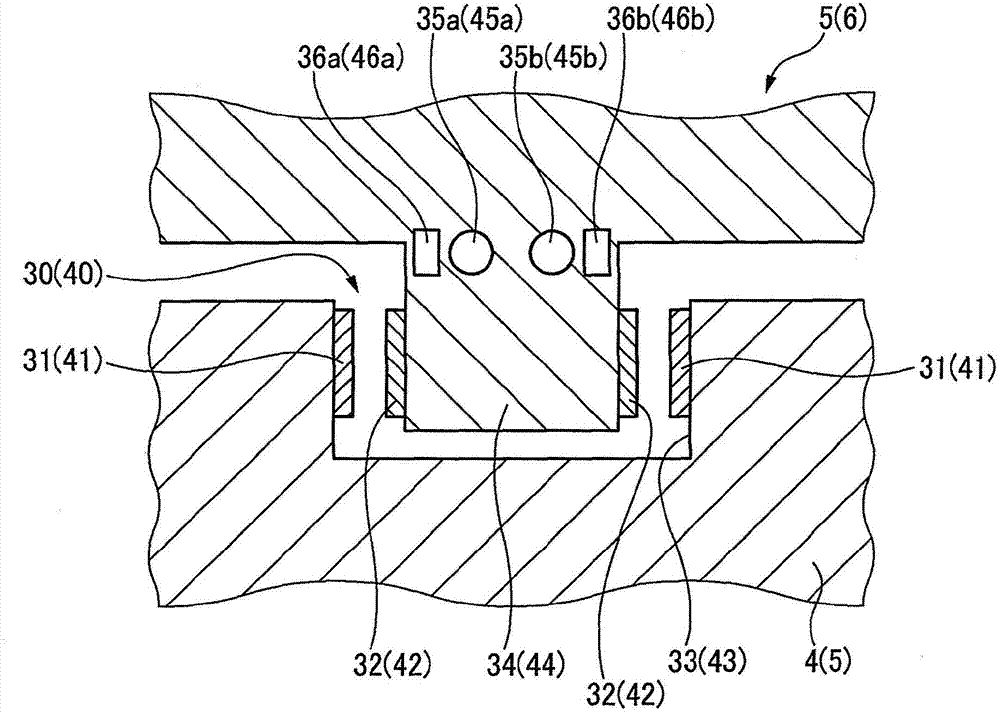

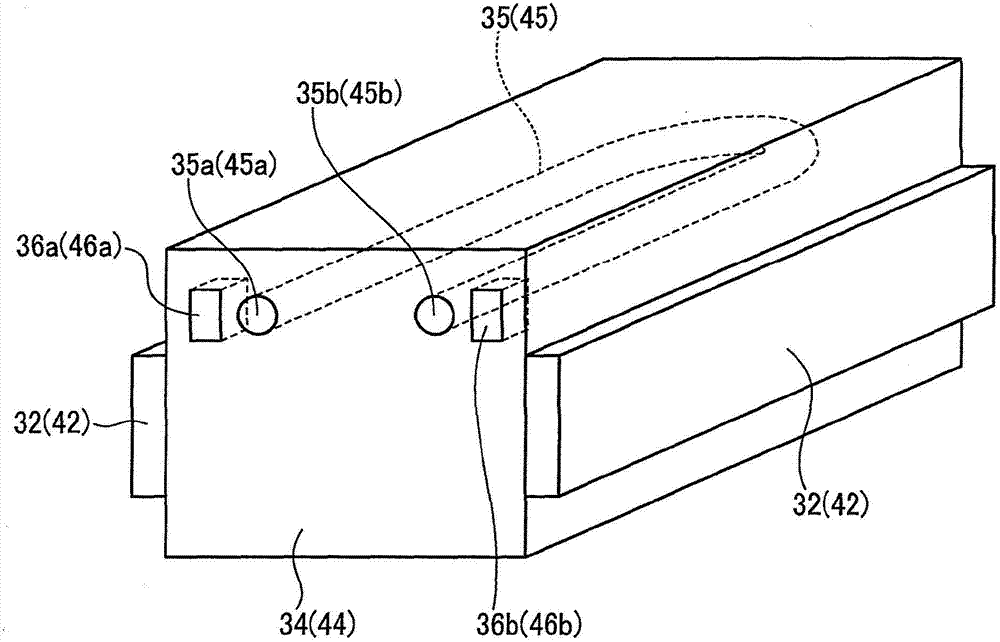

[0155] Below, refer to Image 6 with Figure 7 Next, a proximity exposure apparatus according to a second embodiment will be described. In the first embodiment, the configuration in which the refrigerant circulation passage is arranged along the rotor was described, but this embodiment includes a configuration in which the refrigerant circulation passage is arranged along the stator.

[0156] That is, if Image 6 with Figure 7 As shown, the proximity exposure apparatus according to the second embodiment of the present invention, in addition to having the first and second rotor-side refrigerant circulation passages 35 provided on the X-axis conveying table 5a and the Y-axis conveying table 6a in the above-mentioned embodiment , 45, there are also substantially U-shaped first and second stator side refrigerant circulation passages arranged on the base 4 and the X-axis loading platform conveying mechanism 5 along the first and second stators 31, 41 respectively 70, 80. Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com