Machining method for boss type diamond composite material anti-abrasion belt, mould and anti-abrasion belt

A composite material and processing method technology, applied in the field of drilling tools for oilfield drilling and their manufacturing, can solve problems such as inability to expose diamonds or insufficient exposure, and achieve the effects of less defects, improved processing quality and efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

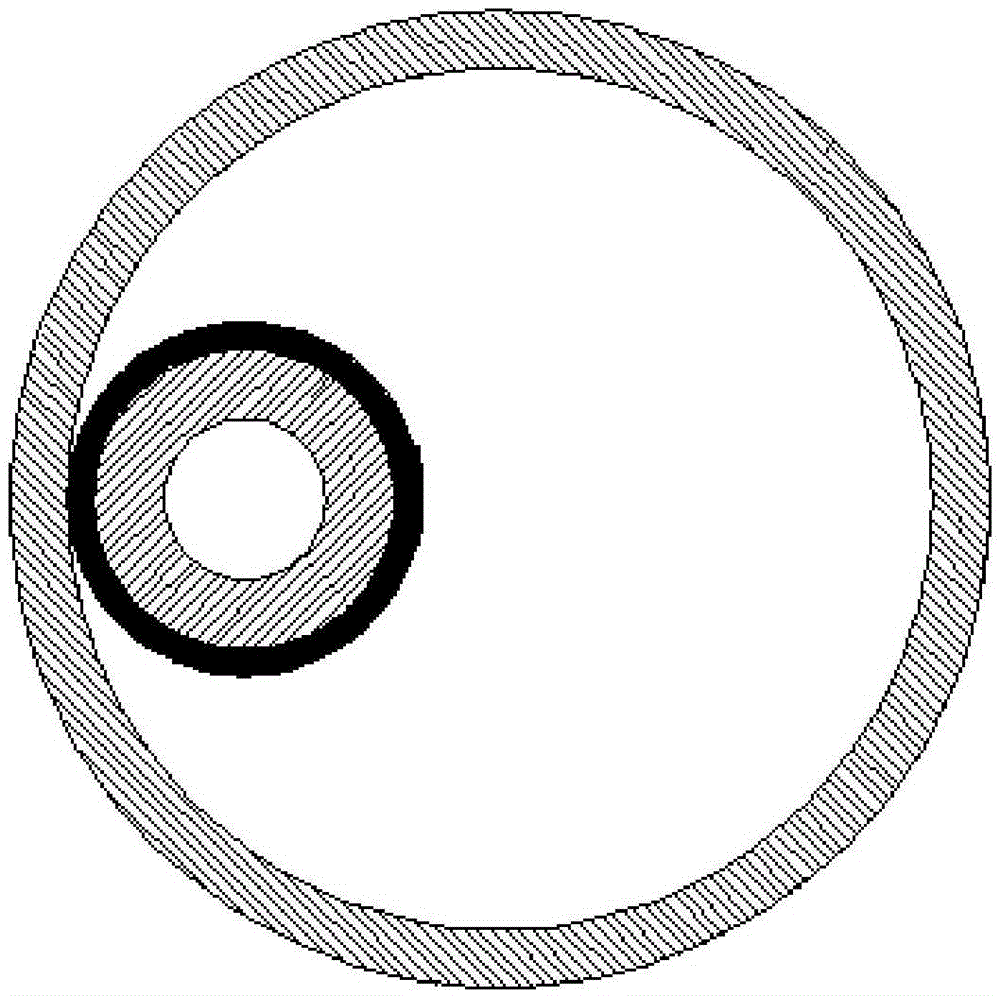

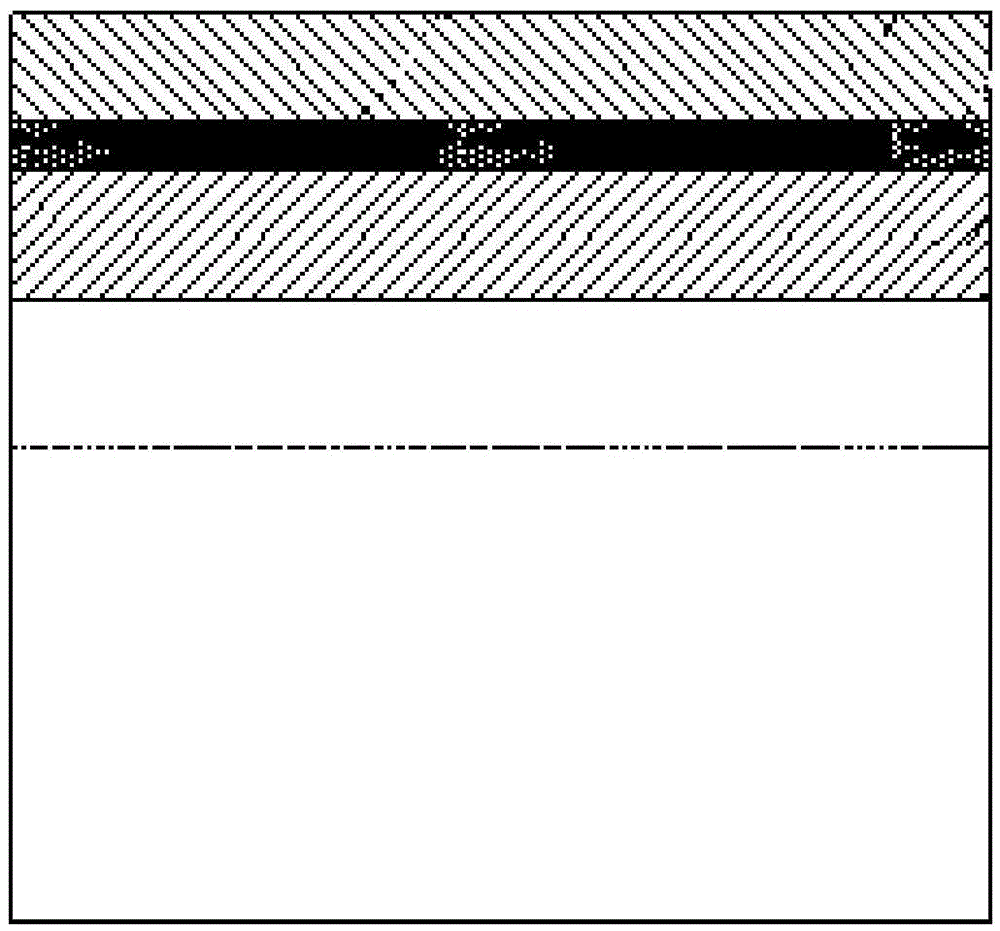

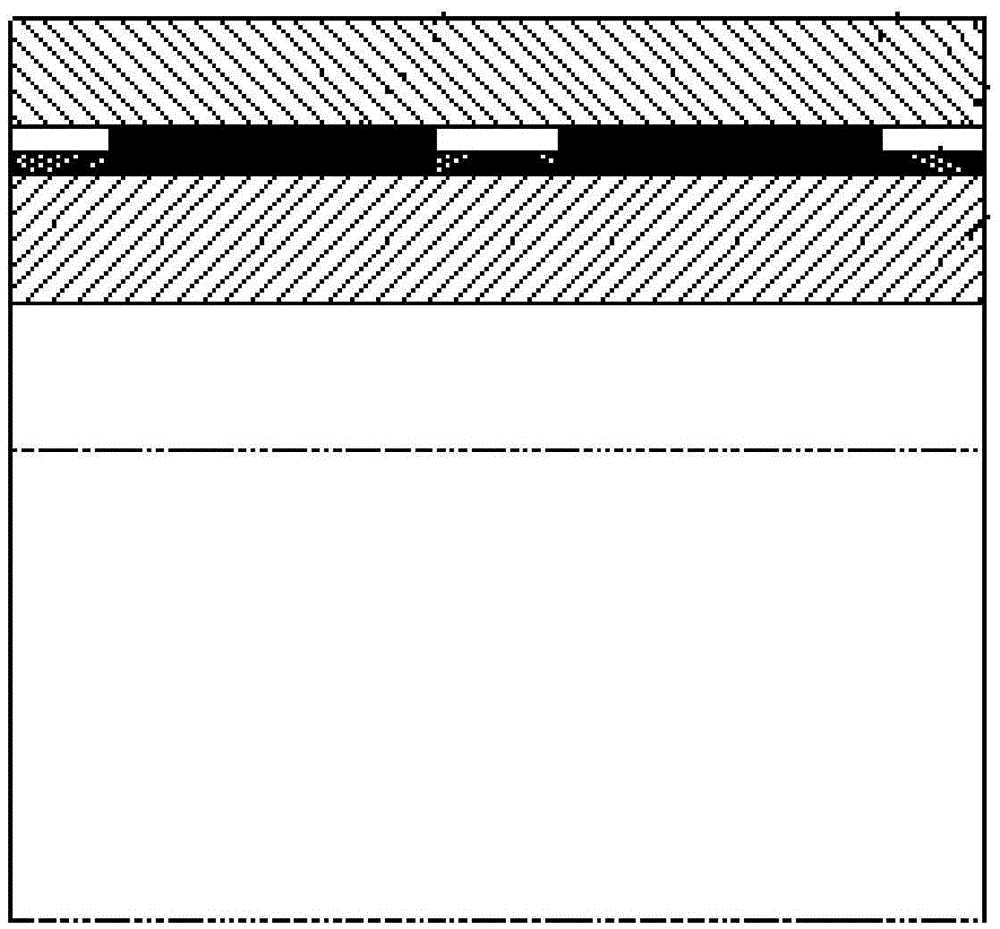

[0032] The embodiments of the present invention provide a method for processing a convex-type diamond composite wear-resistant belt, which adopts a mold of the convex-type diamond composite wear-resistant belt to manufacture the convex-type diamond composite wear-resistant belt. like Figure 5 to Figure 9 As shown, the mold 100 includes an upper mold 1 , a lower mold 2 , a sand core 3 , a sleeve 4 and a collar body 6 . The lower mold 2 includes a sand mold 22 set inside and outside and a ring body 21 made of graphite. The sand mold 22 and the annular body 21 are both cylindrical and placed on the platform 8 horizontally. The axes of the above-mentioned annular body 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com