Work structure for providing scanning path of immersion photoetching machine

A technology of scanning path and lithography machine, which is applied in the field of microelectronics and can solve problems such as low product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with the principle diagram and specific operation embodiments.

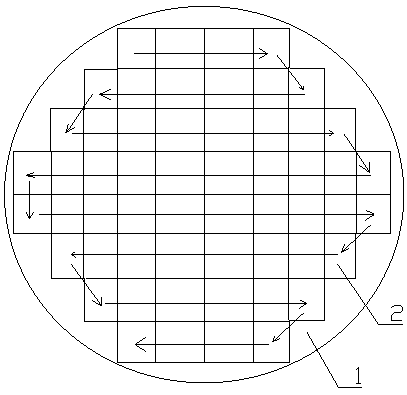

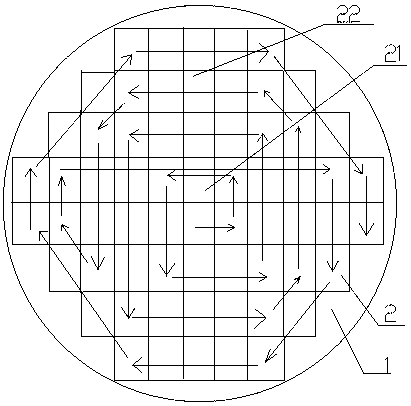

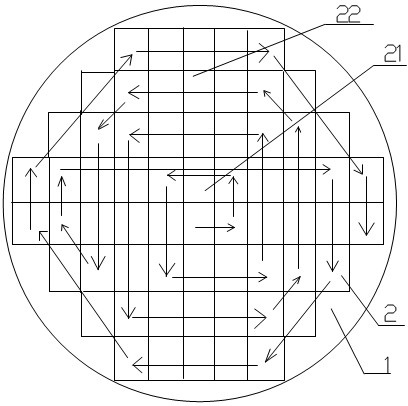

[0017] See figure 2 As shown in the present invention, a working structure for providing a scanning path of an immersion lithography machine specifically includes:

[0018] A silicon wafer 1, the silicon wafer includes a plurality of wafers 2, on the substrate surface of the silicon wafer 1 includes a bottom anti-reflective layer (not shown in the figure), photoresist (not shown in the figure); in order to prevent immersion The volatiles of the photoresist damage the lens of the lithography machine, and a top coating layer (not shown in the figure) may be included on the surface of the photoresist, which can be completely dissolved in the developing liquid Hydrophobic coating. The top coating layer can also be a layer of top anti-reflective coating (TARC), which is coated on the surface of the photoresist to reduce light reflection.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com