Endoscope

An endoscope and bending technology, which is applied in the field of endoscopes, can solve problems such as difficulty in delivery, hooking and detachment of the front end part 201, and insertion obstacle of the insertion part 200.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the drawings are schematic, and it should be noted that the relationship between the thickness and width of each component, the ratio of the thickness of each component, etc. are different from reality, and of course there are also differences in the relationship and ratio of dimensions between the drawings. part.

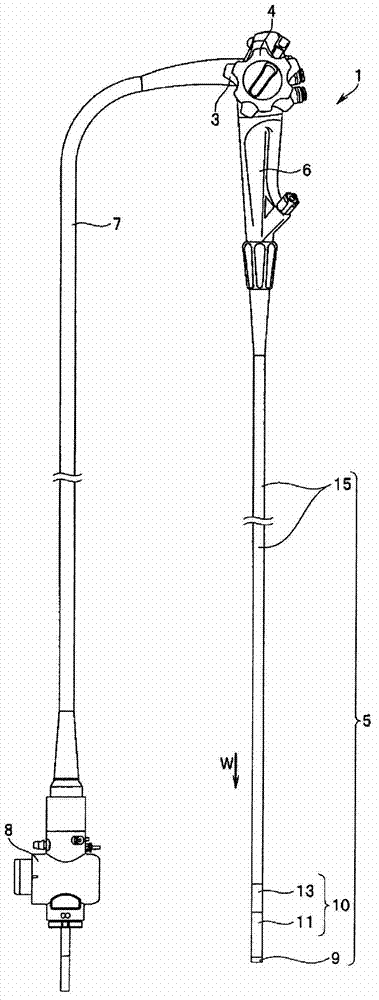

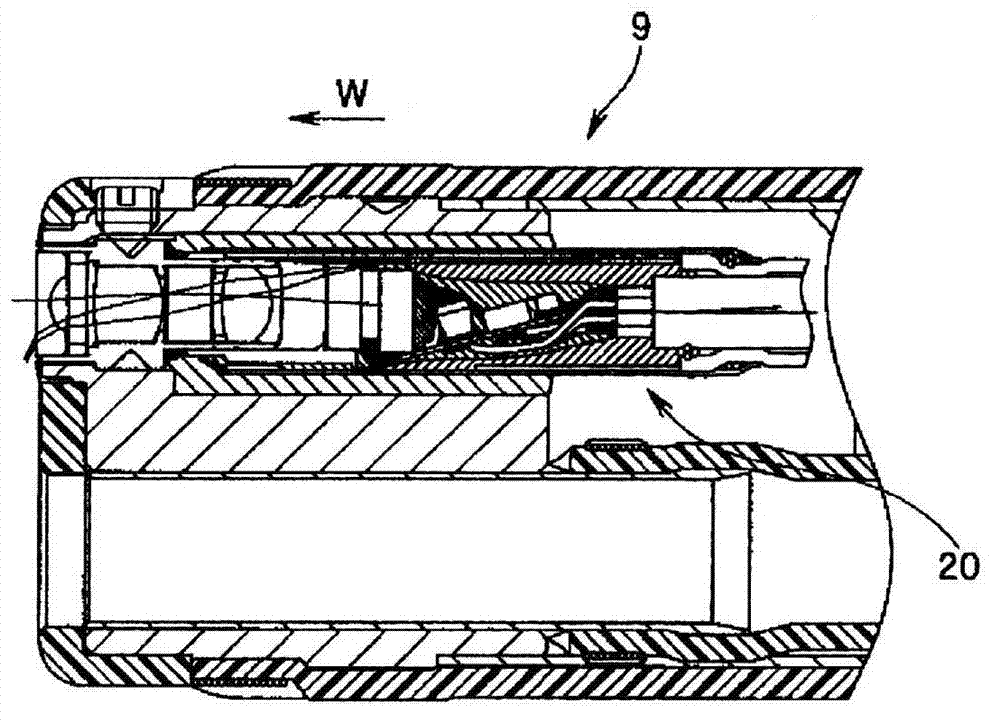

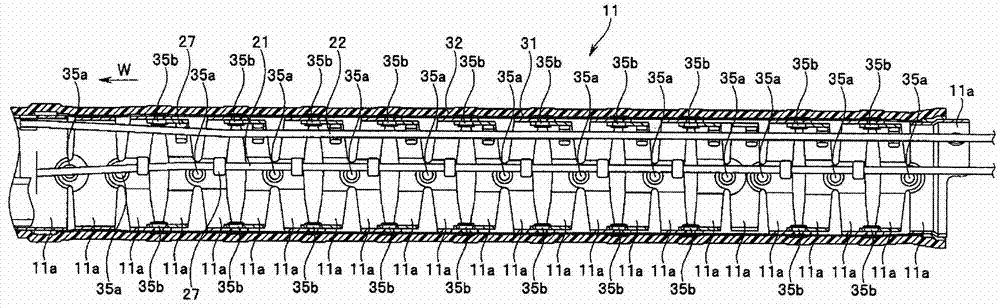

[0066] figure 1 It is a figure showing the endoscope of this embodiment, figure 2 is in figure 1 A partial cross-sectional view of the tip portion provided in the insertion portion of the endoscope, image 3 is in figure 1 Partial cross-sectional view of the active bending part provided in the insertion part of the endoscope, Figure 4 is shown in figure 1 A partial cross-sectional view near the connection site of the active bending part and the passive bending part provided in the insertion part of the endoscope, Figure 5 is in fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com