Dust collecting device for machining area of mitre saw

A technology of dust collection and sawing, which is applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of easy blockage of equipment parts, affect the normal use of equipment, and low labor intensity of workers, and achieve simple structure , Strong practicability, and the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with specific embodiment the present invention is described in further detail;

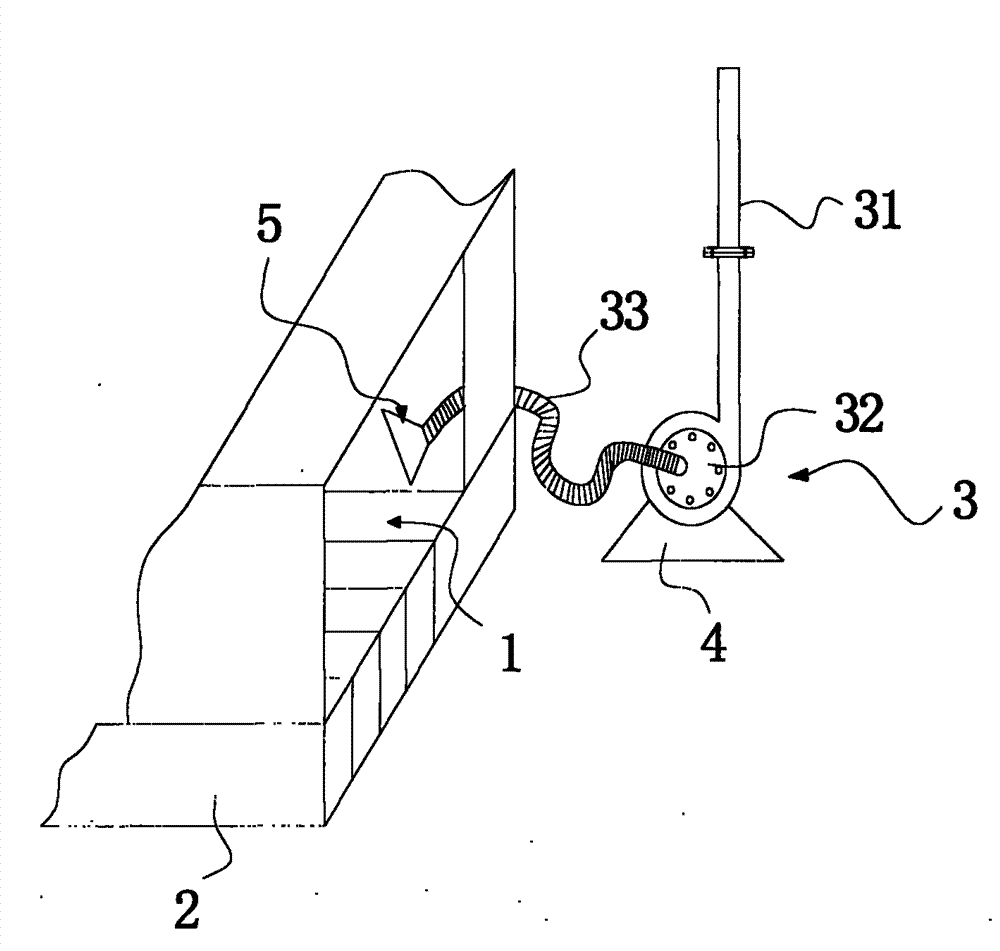

[0010] Such as figure 1 As shown, a dust collection device in a vertical and horizontal saw processing area includes a vertical and horizontal saw 2 with a processing area 1, and a dust collection device 3 is provided in the processing area 1, and the dust collection device 3 is composed of a dust exhaust fan 32 with a dust discharge port 31 And be located at the dust collection pipe 33 that is connected with this dust exhaust blower 32 that is located in processing area 1, dust exhaust blower 32 is fixed on the base 4, is provided with a funnel-shaped collection mouth 5 on dust collection pipe 33. In order to prevent polluting the air and the environment, the dust outlet 31 can be connected with a dust collection bag or a dust collection box.

[0011] Of course, the above description is not intended to limit the present invention, and the present invention is not limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com