A cutting machine tool for metal processing

A cutting machine tool and metal processing technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of cutting fluid splashing, increasing, and cutting fluid polluting the working environment, so as to prevent pollution of the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

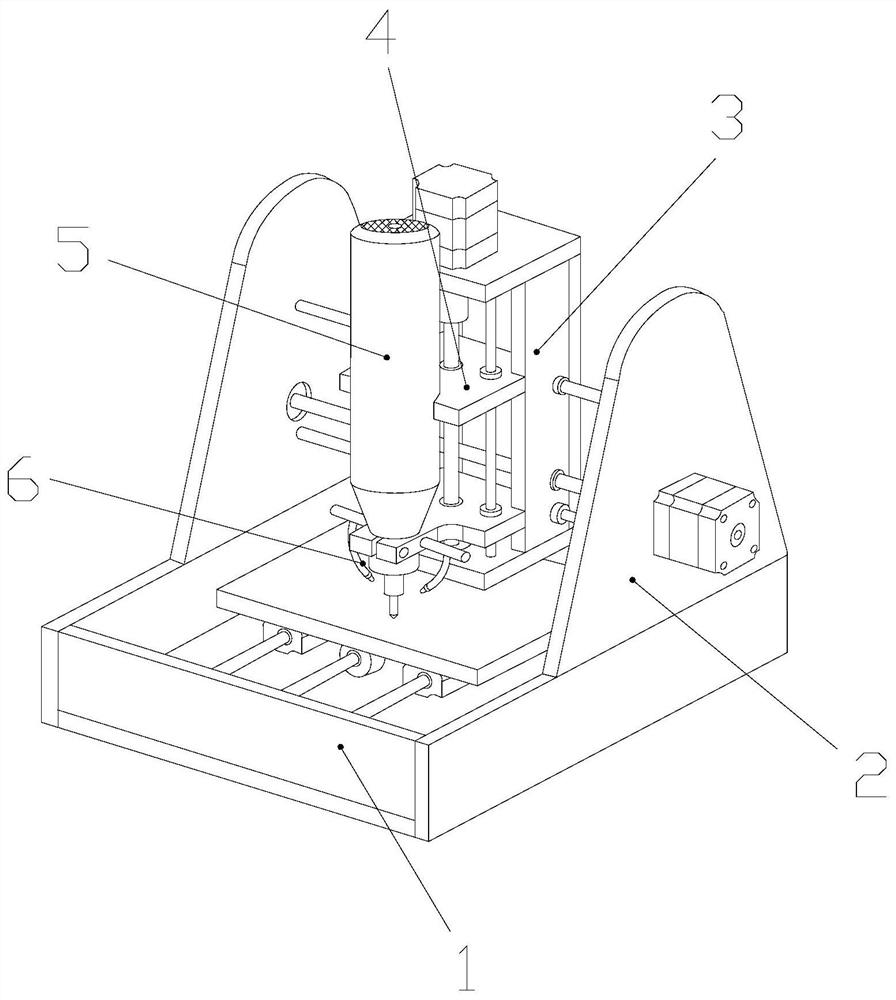

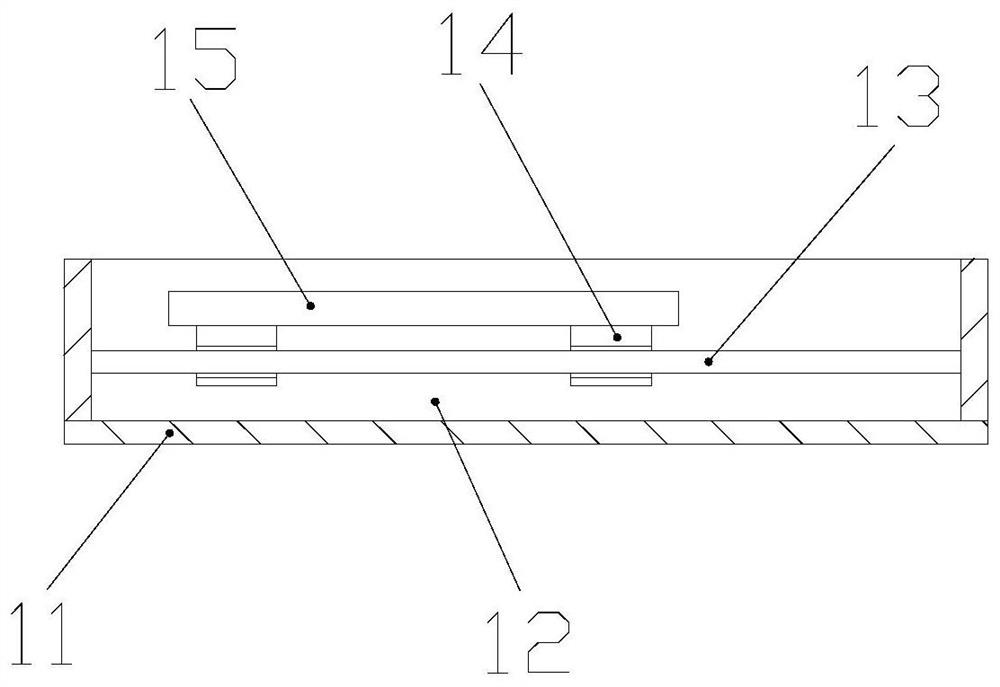

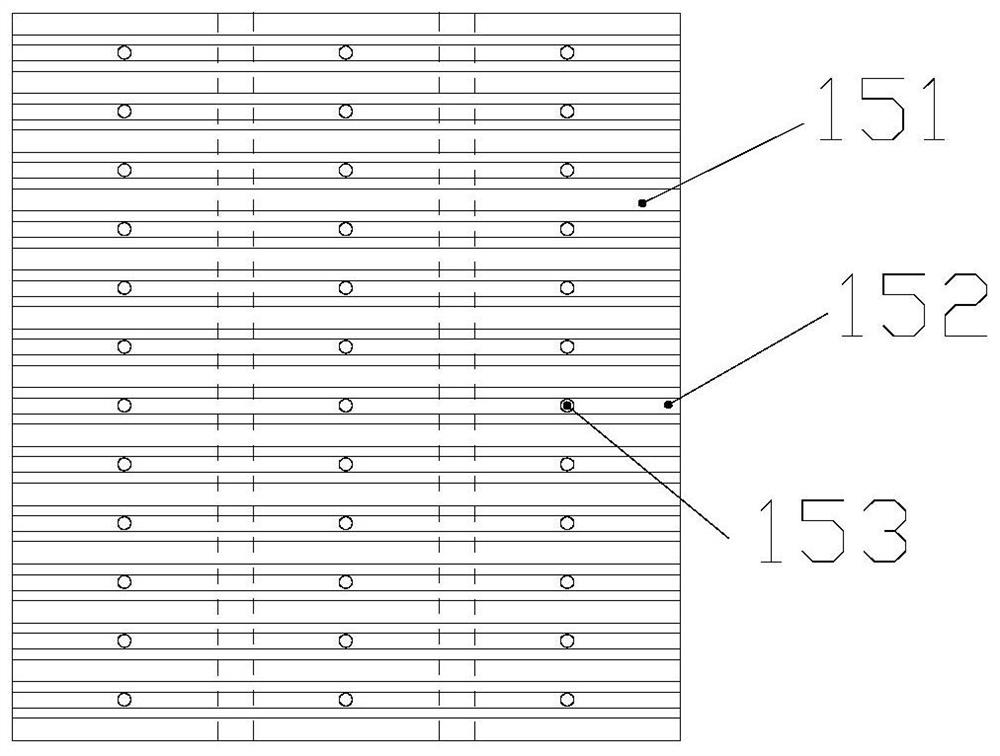

[0027] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

[0028] Its structure includes a working base 1, a side frame 2, a lateral moving frame 3, a longitudinal moving frame 4, a cutting head 5, and a cooling pipe 6. The side frame 2 is vertically installed on the side of the working base 1 and welded together. The lateral moving frame 3 is installed between the side frames 2 and is movably connected, the longitudinal moving frame 4 is embedded in the lateral moving frame 3 and is movably connected, the cutting head 5 is vertically installed on the front end of the longitudinal moving frame 4 and is mechanically connected, The cooling pipe 6 is located on both sides of the cutting head 5; the working base 1 includes an outer box body 11, a storage chamber 12, a guide rail 13, a slider 14, and a workbench 15, and the storage chamber 12 is arranged on the outer box body 11 The inner side is an integrated structu...

Embodiment 2

[0035] Example 2: Please refer to Figure 5-Figure 7 , the specific embodiments of the present invention are as follows:

[0036] The diversion structure 52c includes a sloping plate c1, a diversion cavity c2, a connecting plate c3, a movable rod c4, and a top c5. The diversion cavity c2 is provided on the outside of the sloping plate c1 and is an integrated structure. The connecting plate c3 Vertically installed on the lower end of the inclined plate c1 and welded together, the movable rod c4 is installed on the inner side of the connecting plate c3 and adopts a flexible connection, and the upward end of the inclined plate c1 converges to form the apex c5.

[0037] refer to Figure 5 , the inner side of the connecting plate c3 is provided with a slot hole and extends obliquely parallel to the sloping plate c1, the upper end of the movable rod c4 is slidably connected with the slot hole, and the connecting plate c3 at the lower end of the sloping plate c1 can be moved accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com