Bamboo shoot cutting machine

A flower cutting machine and bamboo shoot technology, which is applied in metal processing and other fields, can solve the problems of low efficiency, short supply, and different thickness of bamboo shoots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

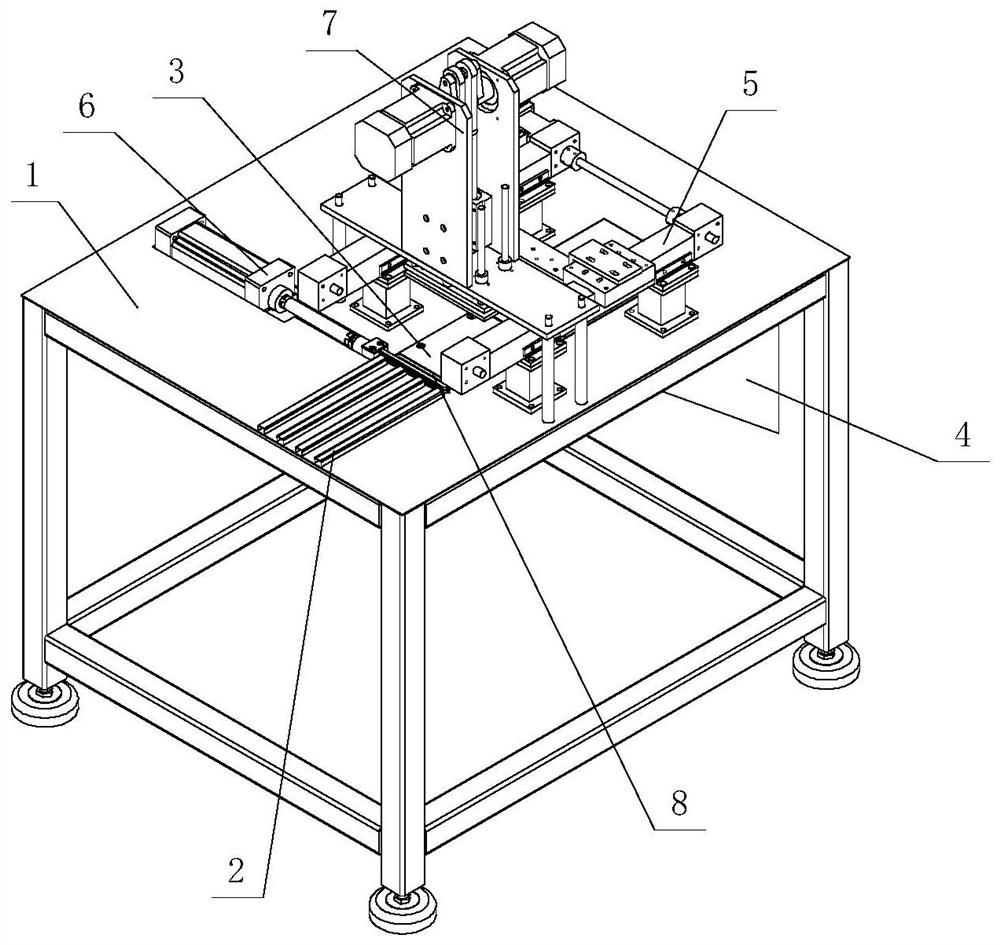

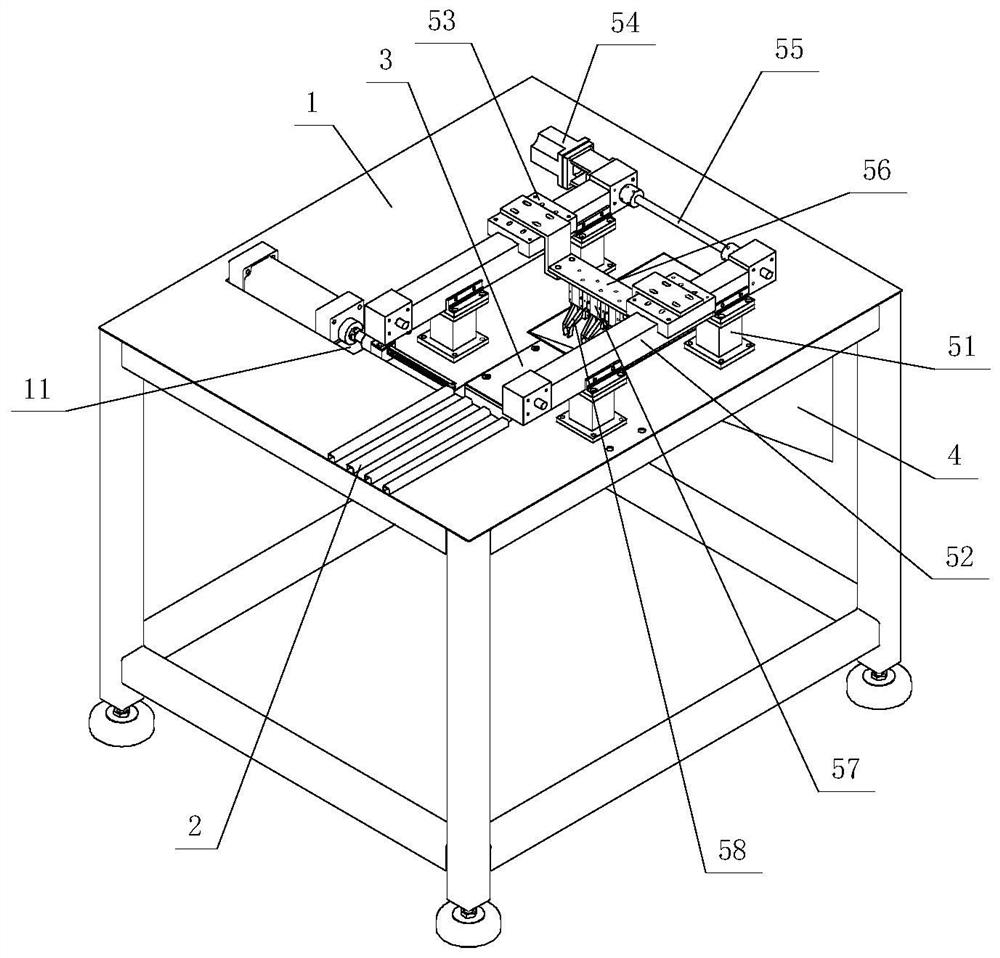

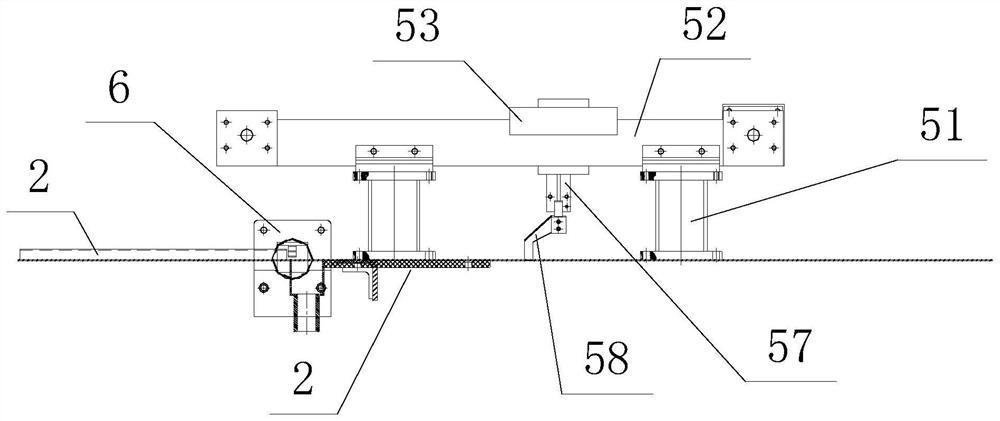

[0033] Such as Figure 1 to Figure 9 As shown, the bamboo shoot flower cutting machine provided in this embodiment includes a workbench 1, a positioning bar 2, a backing plate 3, a drain 4, a clamping mechanism 5, a cross-cutting knife rest 6 and a vertical cutting knife rest 7. A plurality of parallel positioning strips 2 are installed on the surface of one side of the table 1, and a positioning groove for placing bamboo shoots is formed between adjacent positioning strips 2, and a backing plate 3 and a drain 4 are sequentially provided on the workbench 1 on the rear side of the positioning groove. Positioning groove, backing plate 3, drain groove 4 are linearly distributed, so that bamboo shoots are processed bamboo shoots in motion, described backing plate 3 and the workbench 1 of drain groove 4 both sides are installed with driving bamboo shoots from positioning groove toward drain. The clamping mechanism 5 of groove 4 motion, clamping mechanism 5 is used for clamping bamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com