System and method for automatic diverting control

An automatic distribution and control system technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of unreasonable distribution of machine raw materials, material blocking or shortage, etc., to ensure production order and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

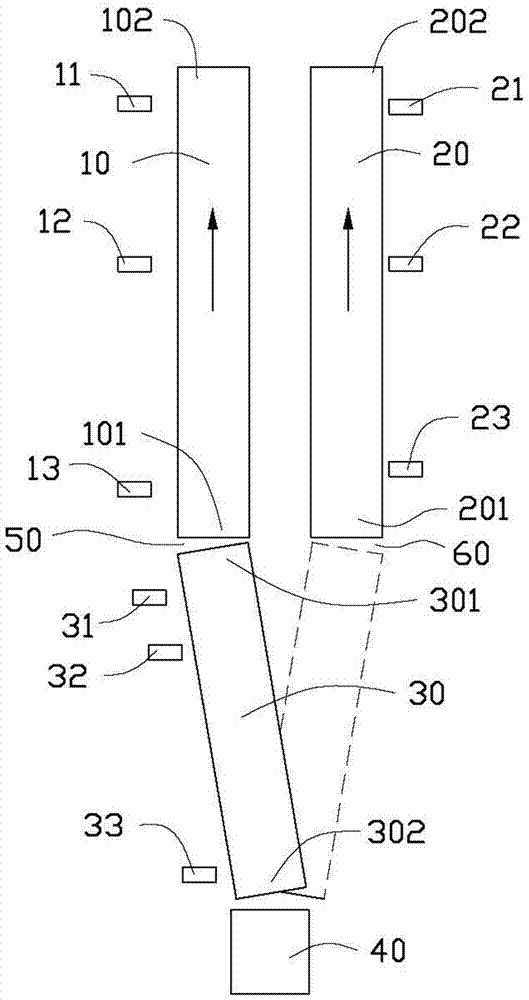

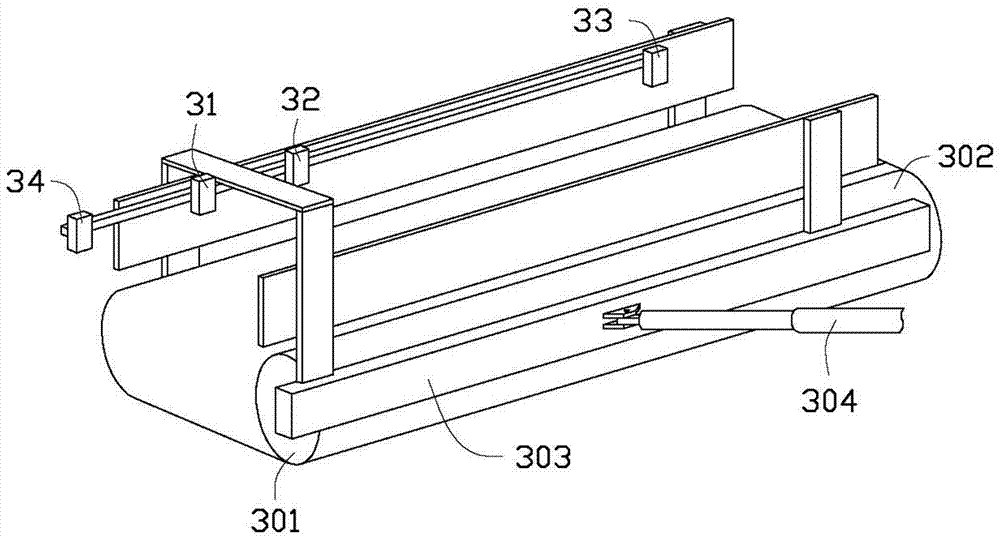

[0021] Please refer to figure 1 , The automatic diversion control system of an embodiment of the present invention includes a first station conveying device 10, a second station conveying device 20, a swing conveying device 30, a feeding device 40 and a control device (not shown). The feeding device 40 is used to supply products to the oscillating conveying device 30 . The swing conveying device 30 includes a movable end 301 adjacent to the first and second station conveying devices 10 , 20 and a fixed end 302 opposite to the movable end 301 . The fixed end 302 is adjacent to the feeder 40 . The control device can control the swing of the movable end 301 of the swing conveying device 30 to reach the first station 50 or the second station 60, thereby connecting with the first station conveying device 10 corresponding to the first station 50, or connecting with the second station 50. The second station conveying device 20 corresponding to the station 60 is connected so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com