Auxiliary device of polyster fibers for changing barrels automatically and quantitatively

A polyester fiber and auxiliary device technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of increasing the amount of waste silk, less tow, and large power consumption, so as to reduce power consumption Power consumption, reduction of waste silk, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

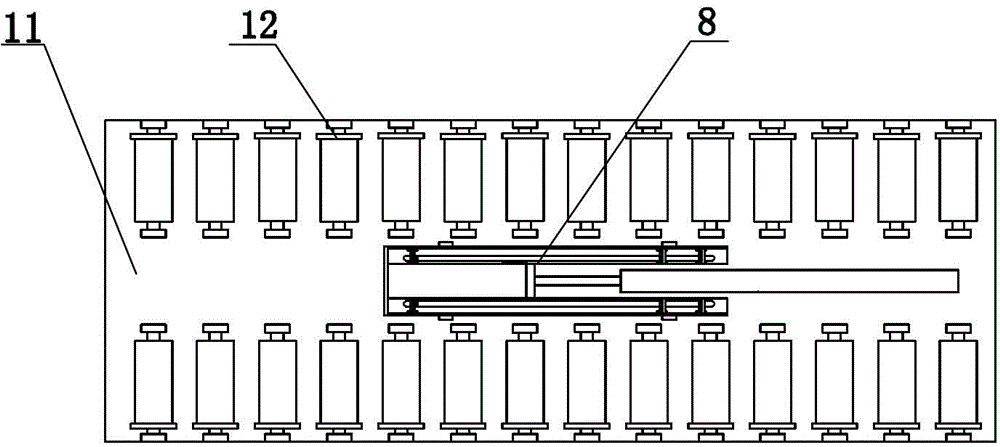

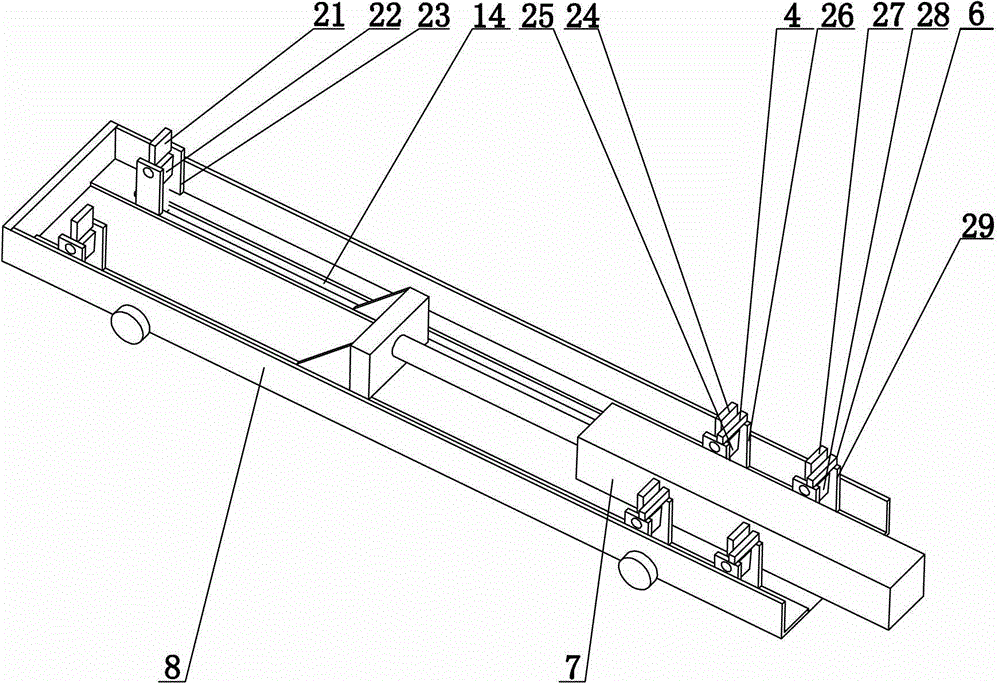

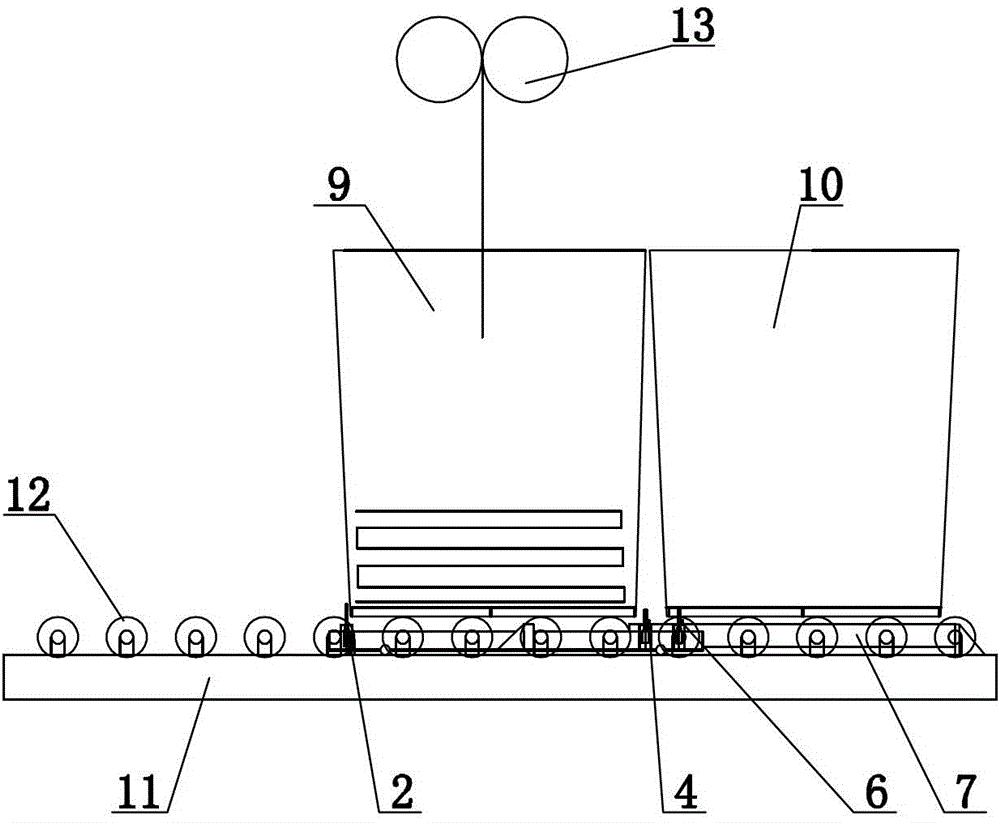

[0015] like figure 1 , 2 An auxiliary device for automatically quantitatively changing barrels of polyester fibers shown in and 4, comprising an integral multi-directional mobile chassis 11 capable of longitudinal and lateral movement, and an oil cylinder for controlling lateral and longitudinal movement is provided at the bottom of the integral multi-directional mobile chassis 11 30. The oil cylinder 30 is connected to the oil station. The inner side of the overall multi-directional mobile chassis 11 is provided with a full row of rollers 12. The trolley 8 is located between the rollers 12. The inner walls on both sides of the trolley 8 are provided for positioning and changing barrels. The gear device, the trolley 8 is connected with the overall multi-directional mobile underframe 11 through the cylinder 7.

[0016] The gear device includes a front stop device for the silk bucket, a rear stop device for the silk bucket, and an empty bucket advancing positioning device. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com