Backlight module and light-emitting diode (LED) display

A technology of backlight module and light source module, applied in the field of LED display, can solve the problems of reducing luminous efficiency, shadow of backlight module, light leakage of liquid crystal screen, etc., and achieve the effect of improving backlight effect, improving heat dissipation efficiency and eliminating dark area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

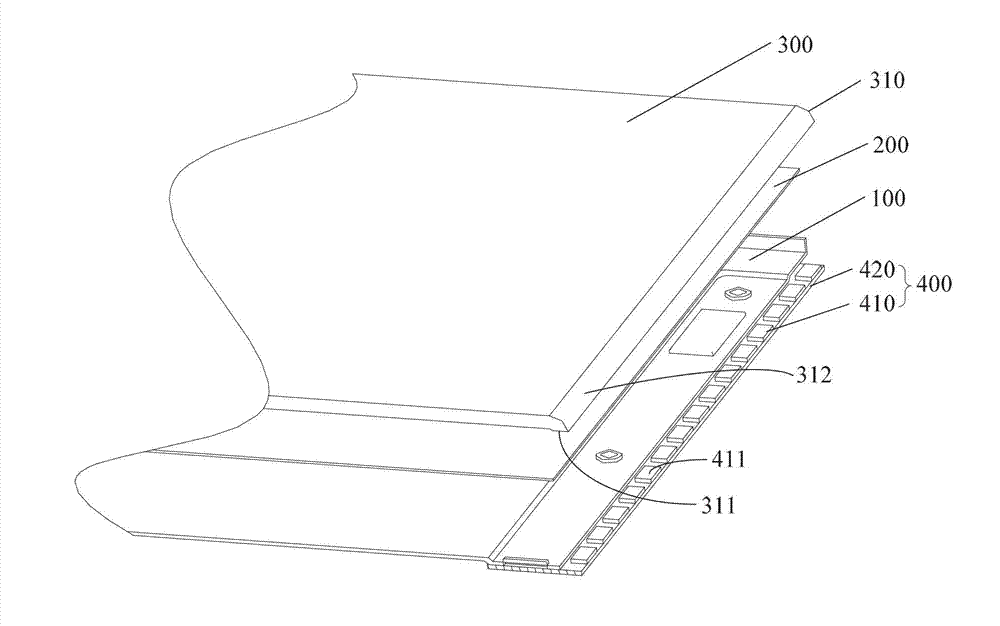

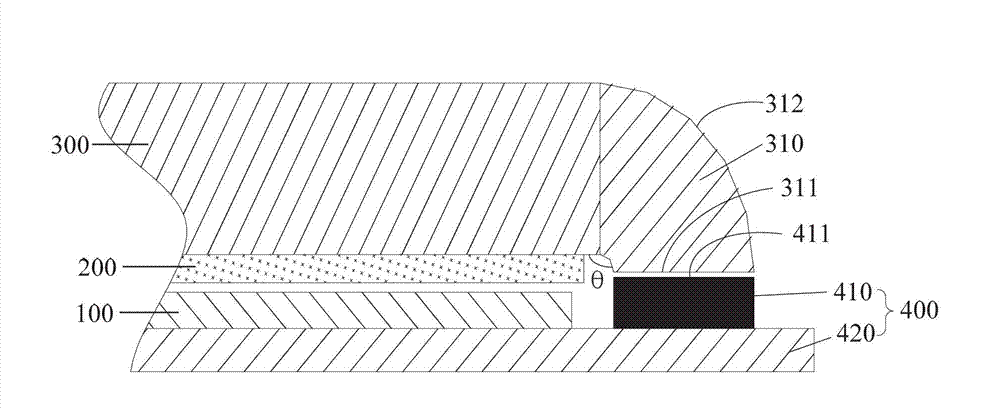

[0021] see Figure 1-Figure 2 A preferred embodiment of the backlight module of the present invention is shown, the backlight module includes a light source module 400 with a light-emitting surface and a backplane 100, a reflection sheet 200, and a light guide plate 300 stacked in sequence, and the light guide plate One end of 300 is bent and extended toward the backplane 100 to form a bent part 310 with an outer surface 312 that is opaque. The light-emitting surface 411 is set opposite to the light-incident surface 311 , and it is best to be in close contact in order to reduce the loss of the light source. That is, as shown in the figure, the light incident surface of the light source module is not facing the side of the light guide plate as in the prior art, but faces the back of the light guide plate. The bending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com