Device for measuring coaxiality of bearing seat of aero-engine combustion chamber casing

An aero-engine, coaxiality measurement technology, applied in mechanical measurement devices, measurement devices, mechanical devices, etc., to achieve the effects of real measurement data, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

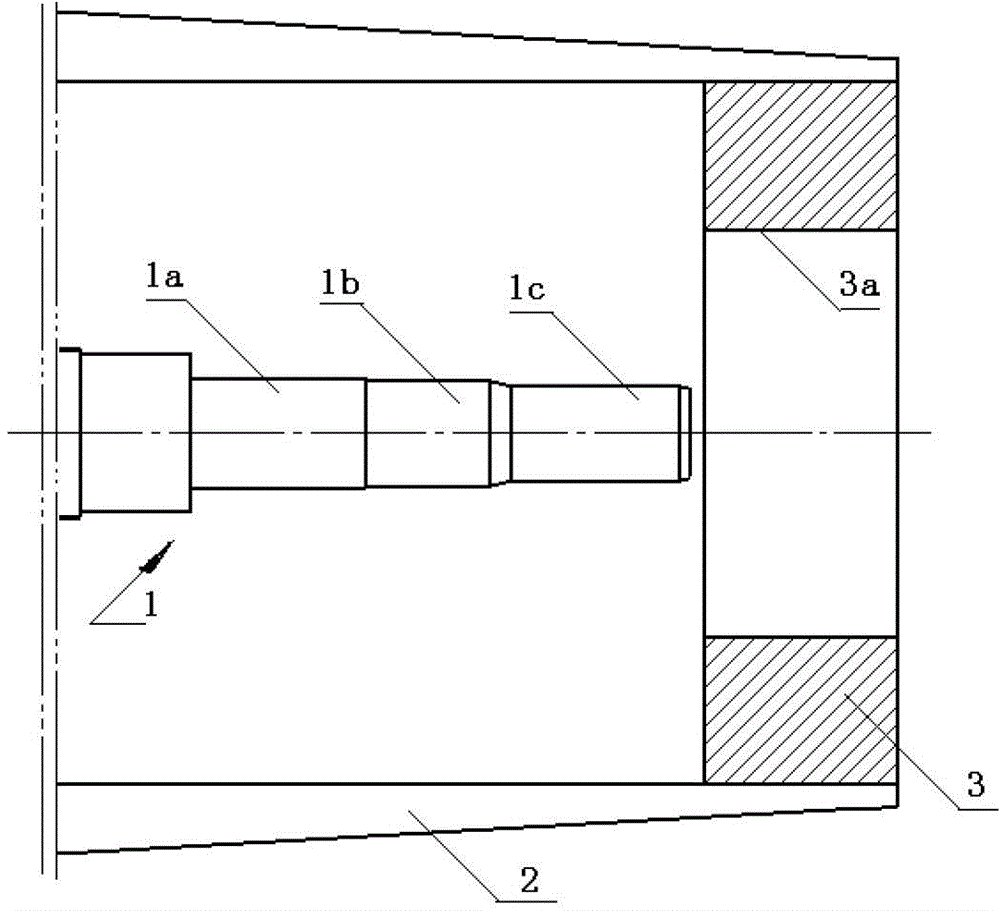

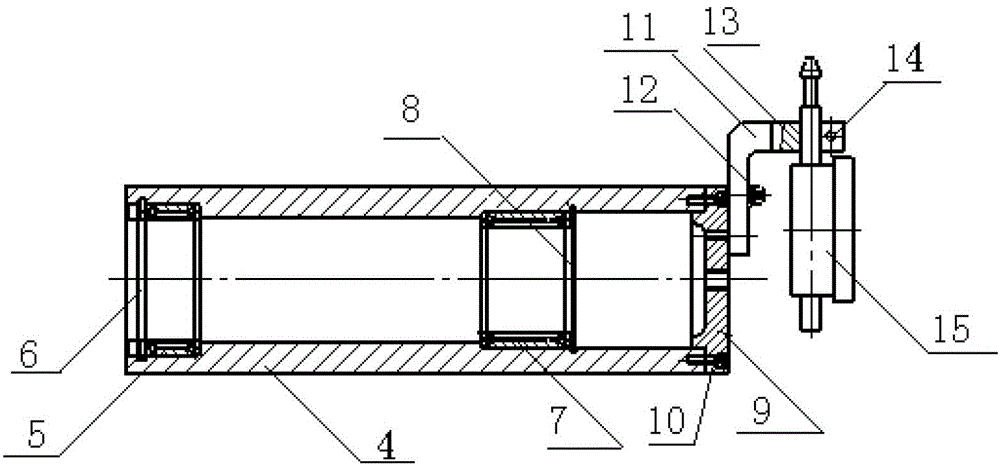

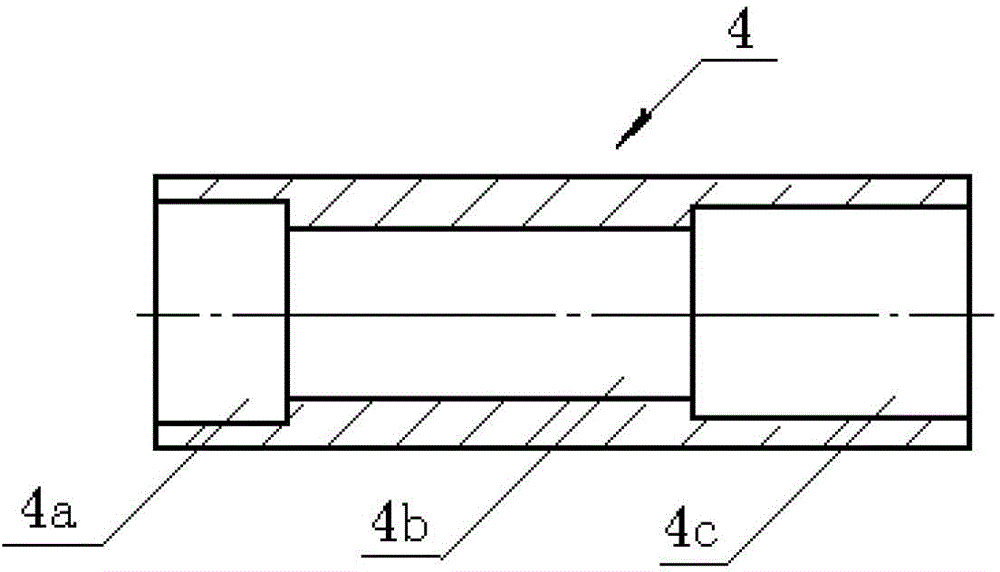

[0011] The present invention will be described in further detail below. see Figure 1 to Figure 4 , aero-engine combustor case bearing seat coaxiality measuring device is characterized in that it consists of a positioning sleeve 4, a front needle roller bearing 5, a front stop ring 6, a rear needle roller bearing 7, a back stop ring 8, an end cover 9. End cover screw 10, bracket 11, bracket screw 12 and dial indicator 15; the positioning sleeve 4 is a cylinder, and the inner hole of the positioning sleeve 4 is divided into three sections: left, middle and right, and the left section hole 4a and the inner diameter of the right section hole 4c is greater than the inner diameter of the middle section hole 4b, the front needle roller bearing 5 is installed in the left section hole 4a and maintains a transition fit, the right end surface of the front needle roller bearing 5 and the left section hole 4a and the middle section hole 4b The end face of the step is fitted, the front st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com