Quasi-static in-situ biaxial tensile property testing instrument

A technology of biaxial stretching and testing instruments, which is used in instruments, scientific instruments, and the use of stable tension/pressure to test the strength of materials. Achieve the effect of true measurement data, elimination of angle offset, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

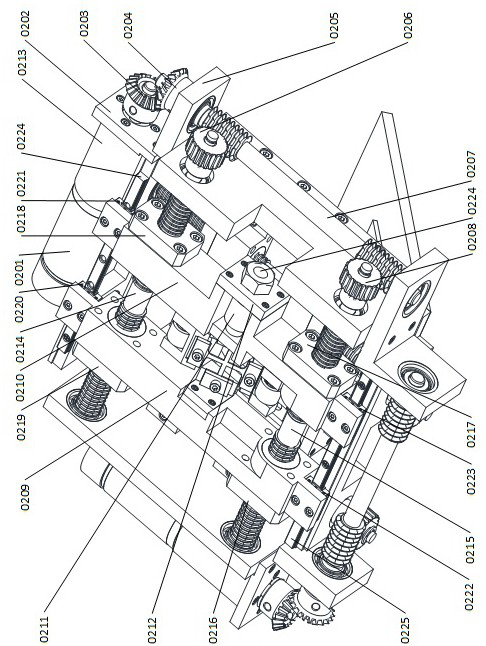

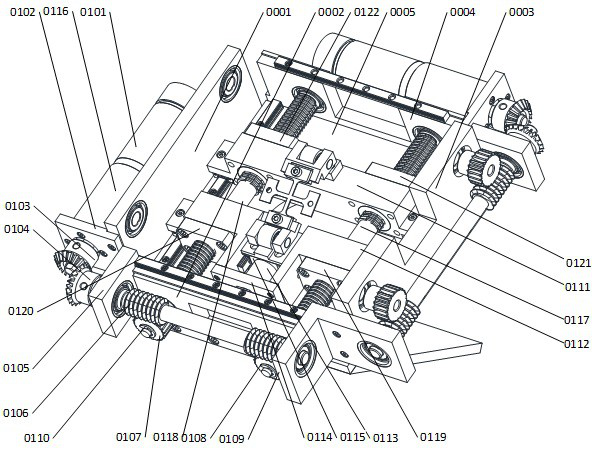

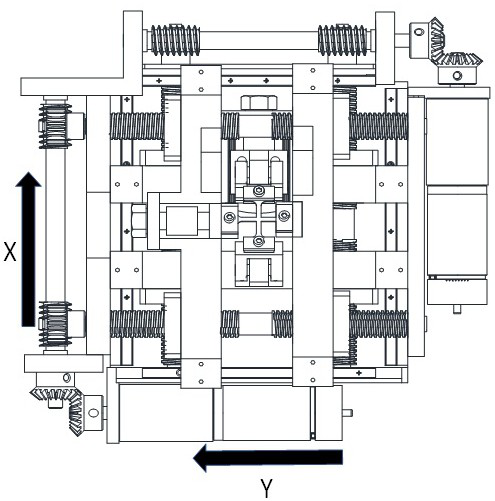

[0025] see Figure 1 to Figure 7 As shown, the present invention provides a quasi-static in-situ biaxial tensile performance testing instrument capable of providing a plane stress state for a tested sample under a scanning electron microscope, including a motor drive unit, a transmission unit, a clamping unit, and a detection unit . The driving unit is composed of two DC servo motors, which provide power sources to the XY directions respectively; the transmission unit uses two pairs of bidirectional trapezoidal screw to drive the nut to realize the drive of the fixture; the clamping unit relies on the sliding nut seat to install the clamp body for testing Clamp the parts to achieve load loading. Use the 25° inclined fixture and cooperate with the 45° inclined angle bracket to realize that the measured area of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com