Clamp for mechanical property test of welding of steel-bar truss

A steel truss, test technology, applied in the direction of applying stable shear force to test material strength, scientific instruments, strength characteristics, etc., can solve the problem of inability to accurately reflect the shear force of welding points, the influence of welding point shear performance, and the need Welding equipment and other problems, to achieve the effect of simple structure, novel idea and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

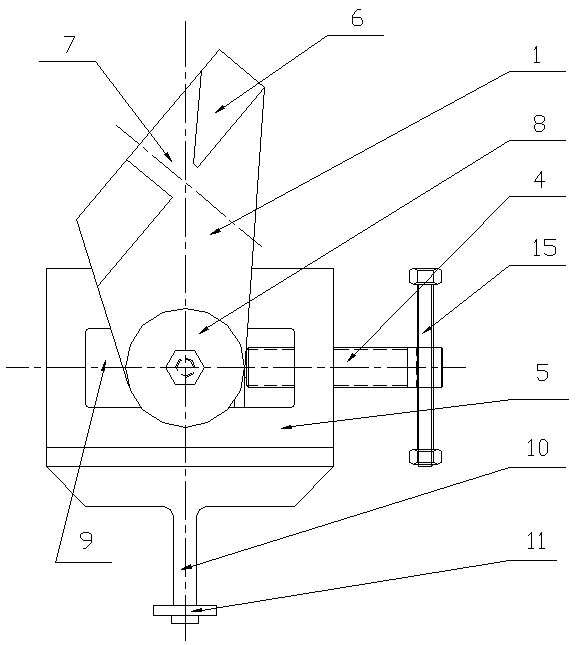

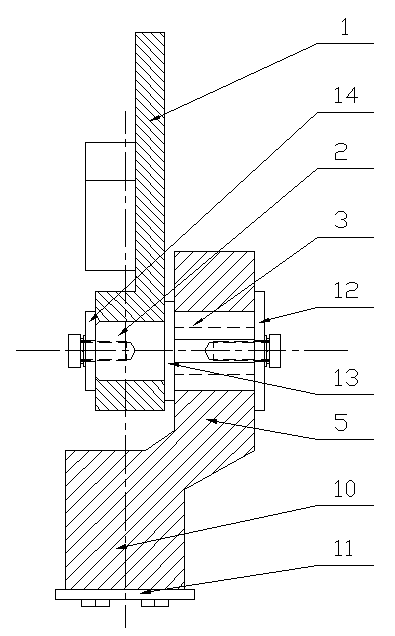

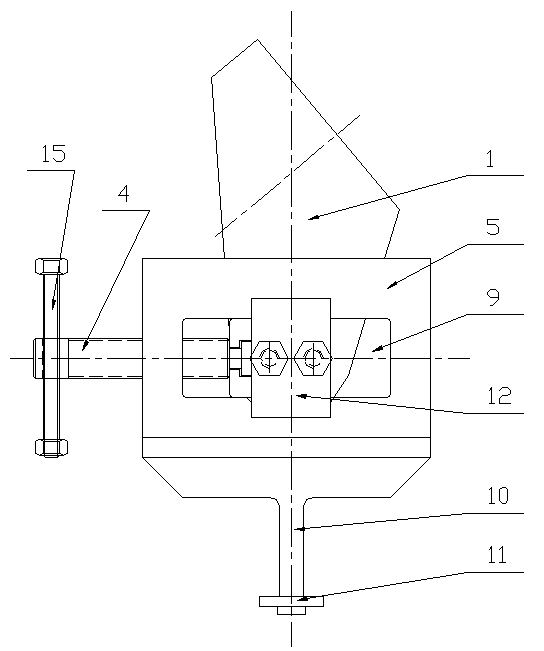

[0029] (1) The sample is made of a reinforced truss with a height of 190 mm, and the angle between the abdominal reinforcement and the upper chord is 62 degrees. According to the sampling rules for shear resistance samples, a sample with solder joints is intercepted on the upper chord. The length of the abdominal reinforcement is not less than 100 mm. The rib is cut off at 150mm from the welding point.

[0030] (2) Install the fixture The bottom plate of the fixture is fixed at one end of the tensile testing machine.

[0031] (3) Clamping the sample The string bars are placed on the lower edge of the hook head, the web bars are placed in the opening groove of the sample, and the web bars are fixed at the other end of the tensile testing machine.

[0032] (4) Adjust the main hook Turn the adjusting bolt, the center of rotation of the positioning shaft moves 19 mm to the right, and the bevel angle of the clamp is 62 degrees to ensure that the force direction of the abdominal mus...

Embodiment 2

[0034] Example 2 The method is the same as in Example 1, and the relevant test data are listed in Table 1, and the test data are listed in Table 2.

Embodiment 3

[0035] Example 3 The method is the same as that in Example 1, and the relevant test data are listed in Table 1, and the test data are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com