Contact type thin plate thickness manual measurer

A contact type, measuring instrument technology, applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of low measurement accuracy, complex structure, low cost, etc., to simplify the complexity, ensure the measurement accuracy, and reduce the hardware cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

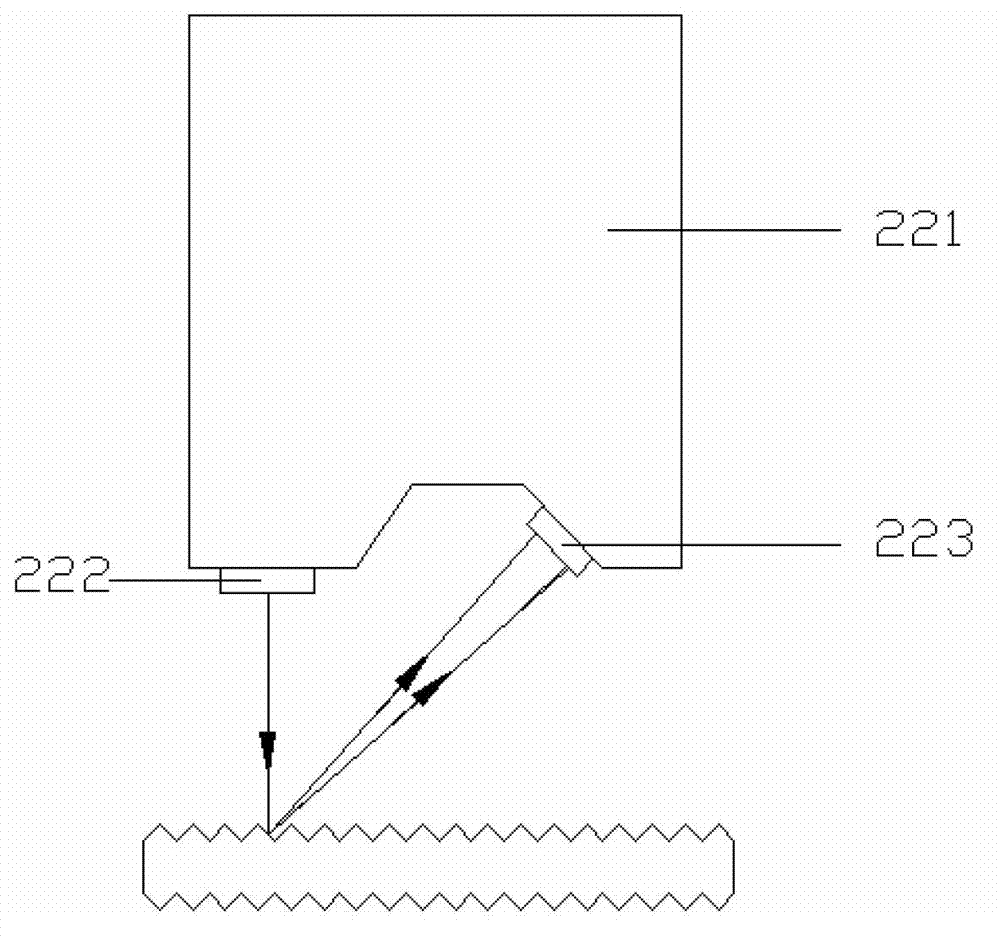

[0029] Such as image 3 As shown, when working, the measurement steps of thin sheet thickness are as follows:

[0030] First install a standard block with a standard height on the fixed platform, and its height value is X0;

[0031] Slide the slide bar 21 of the measuring mechanism so that the light-emitting window 222 of the contact probe 22 is vertically aligned with the standard block;

[0032] The light-emitting window 222 of the touch probe 22 emits a light beam, and the light beam reaches the surface of the standard block for reflection. The light-receiving window 223 is displaced from the theoretical reflection point Z0, and reflected to the Z1 position. The control system records the value;

[0033] Remove the standard block, place the plate to be tested, and allow the light-emitting window 222 of the touch probe 22 to be vertically aligned with the surface of the plate;

[0034] The light-emitting window 222 of the touch probe 22 emits a light beam, which reaches th...

Embodiment 2

[0039] Such as Figure 4 As shown, when working, the measurement steps of thin sheet thickness are as follows:

[0040] First install a standard block with a standard height on the fixed platform, and its height value is X0; slide the slide bar of the measuring mechanism, so that the probe of the touch probe is vertically aligned with the standard block; the touch probe 22 in the vertical direction Begin to move downward along the initial position Z0 of the slide bar 21 until the probe touches the surface of the standard block. At this time, the contact probe drops to the Z1 position, and this time is set as the measurement zero point, corresponding to the standard block 24 having a thickness of X0, the control system of the displacement sensor records this value;

[0041] Move the touch probe from Z1 back to the Z0 position, remove the standard block, place the thin plate to be tested, and let the touch probe drive the probe downward from the Z0 position again until the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com