Ultrasonic concrete detection probe

A technology for detecting probes and concrete, used in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of fuzzy detection results, troublesome operation, and unintuitive detection methods, and achieve simple operation and reduce detection. effect of time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

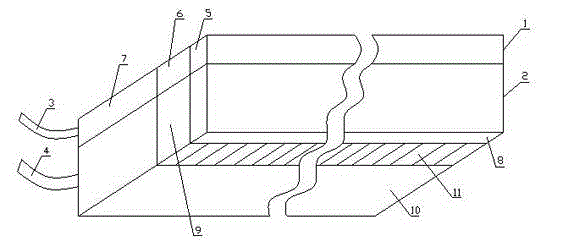

[0020] like figure 1 An embodiment of the ultrasonic concrete detection probe of the present invention is shown, the detection probe is composed of a high-power signal transmitting probe 1 and a high-power signal receiving probe 2, the effective The area adopts a ratio of 2:1 or greater than 2:1. The high-power signal transmitting probe 1 is connected to a single-channel communication cable 3 , and the high-power signal receiving probe 2 is connected to a 28-core multi-channel communication cable 4 . The high-power signal transmitting probe 1 consists of the first matching layer 5, the emitting layer 6 and the first sound-absorbing layer 7 from front to back. The emitting layer 6 is cut transversely into multiple arrays with a pitch of 1mm. The positive and negative electrodes of each array in parallel. The high-power signal receiving probe 2 consists of a second matching layer 8, a transducer layer 9 and a second sound-absorbing layer 10 from front to back. The signal core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com