Liquid crystal module and fixing structure of driver board of liquid crystal module

A liquid crystal module and fixed structure technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of TV burn-in, burn-out driving circuit, easy formation of water, etc., and achieve the effect of not easy to short-circuit burn-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

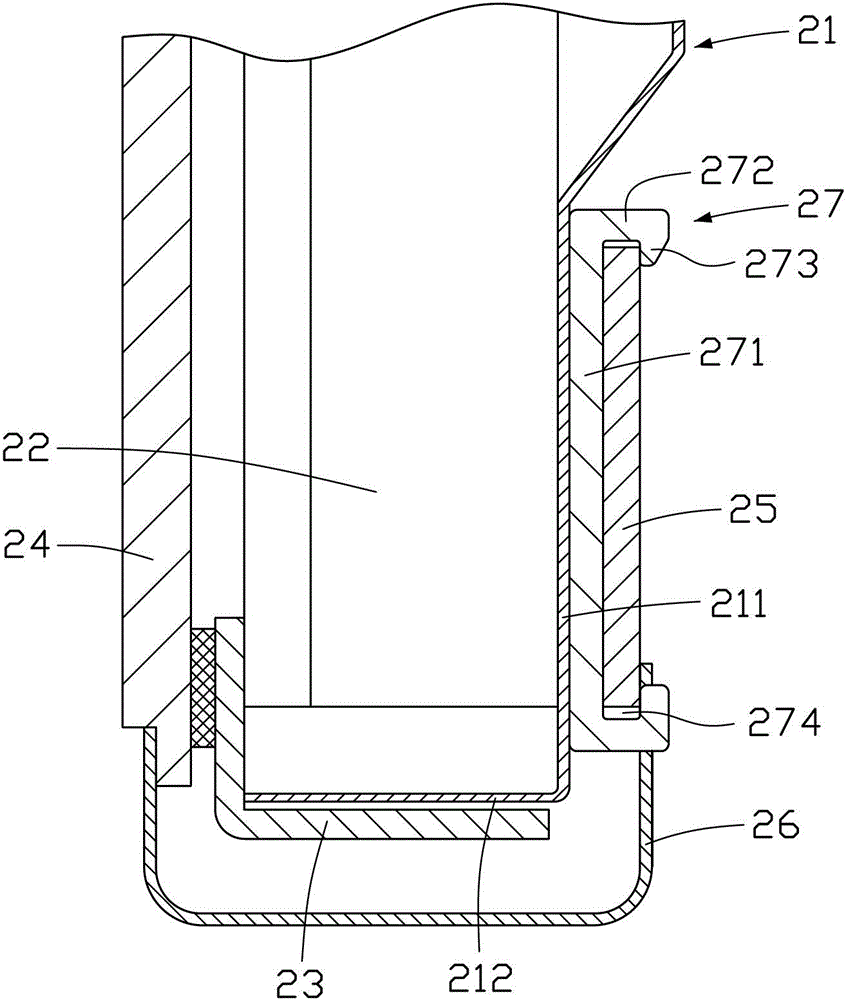

[0016] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

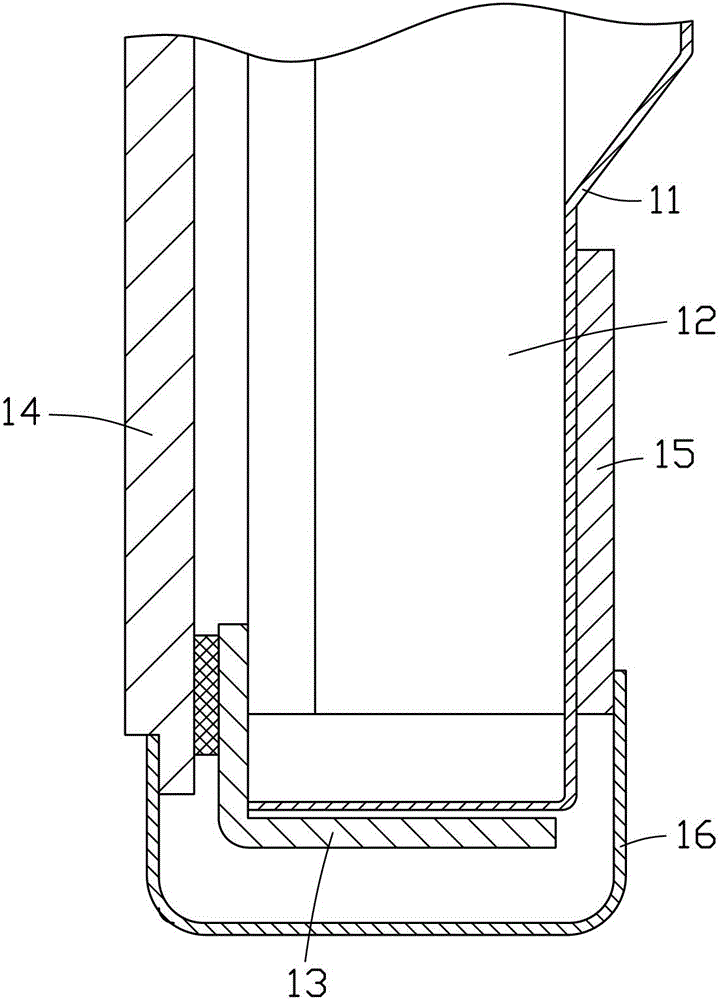

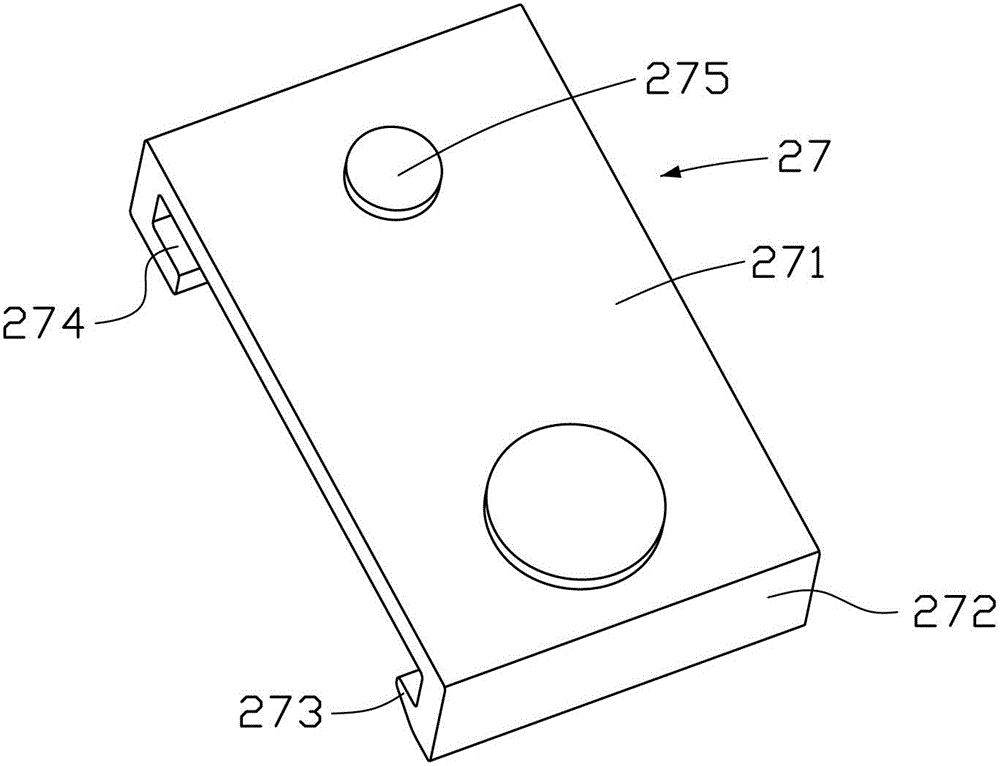

[0017] Please refer to figure 2 The liquid crystal module in the embodiment of the present invention includes a backplane 21 , a backlight module 22 , a plastic frame 23 , a liquid crystal panel 24 , a driving board 25 , a connecting soft board 26 and a fixing bracket 27 . The backlight module 22 is disposed on a surface of the backplane 21 , and the liquid crystal panel 24 is disposed above the backlight module 22 . The sealant 23 is disposed between the liquid crystal panel 24 and the backlight module 22 . The connecting flexible board 26 is arranged on the edge of the liquid crystal module, and electrically connects the driving board 25 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com