Fuel feed device and method for producing such a fuel feed device

A fuel supply and fuel distribution technology, which is applied to fuel injection devices, special fuel injection devices, fuel injection control, etc., can solve problems such as fuel leakage, leakage risk, and increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

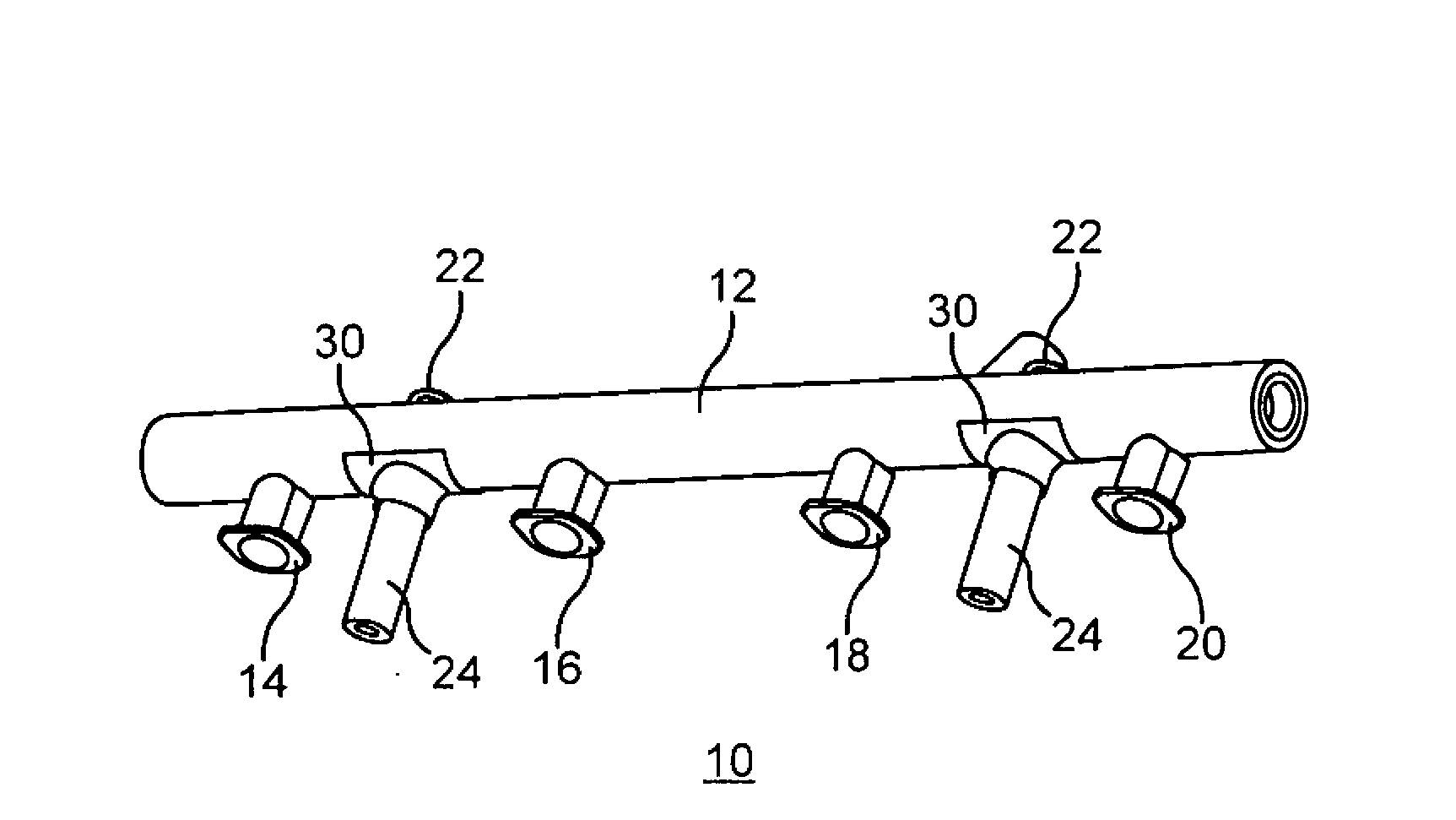

[0034] figure 1 A high-pressure fuel accumulator 10 for a direct-injection gasoline or diesel engine is shown with a fuel rail 12 . When the Otto or Diesel engine is running, the fuel is pressurized by the high-pressure pump and delivered into the fuel rail 12 , which distributes the fuel to the injectors. The injectors inject fuel into the corresponding cylinders. For this purpose, receptacles 14 , 16 , 18 and 20 of high-pressure fuel accumulator 10 are provided, into which receptacles are each fitted one injector and which can thus be supplied with fuel from fuel rail 12 .

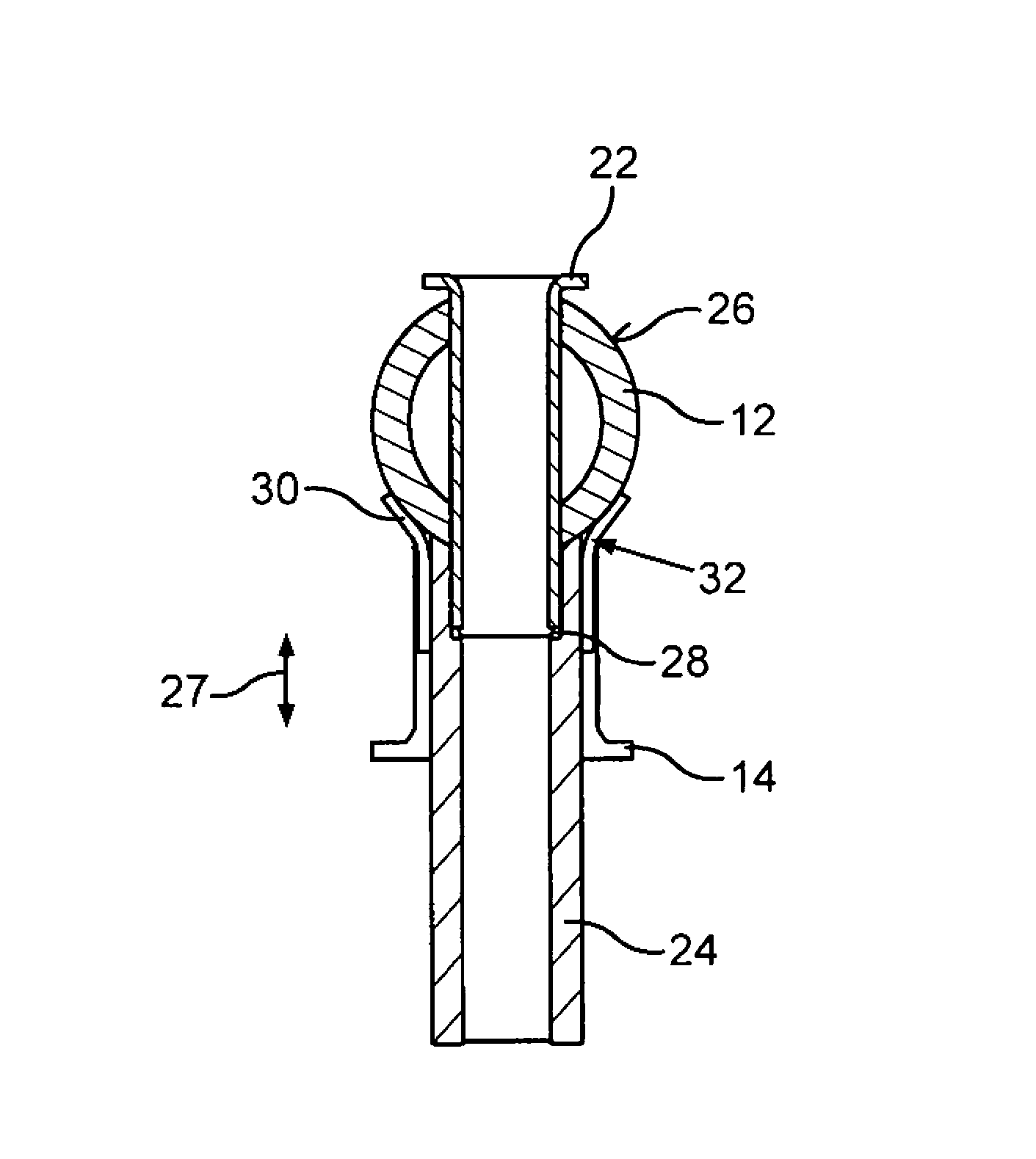

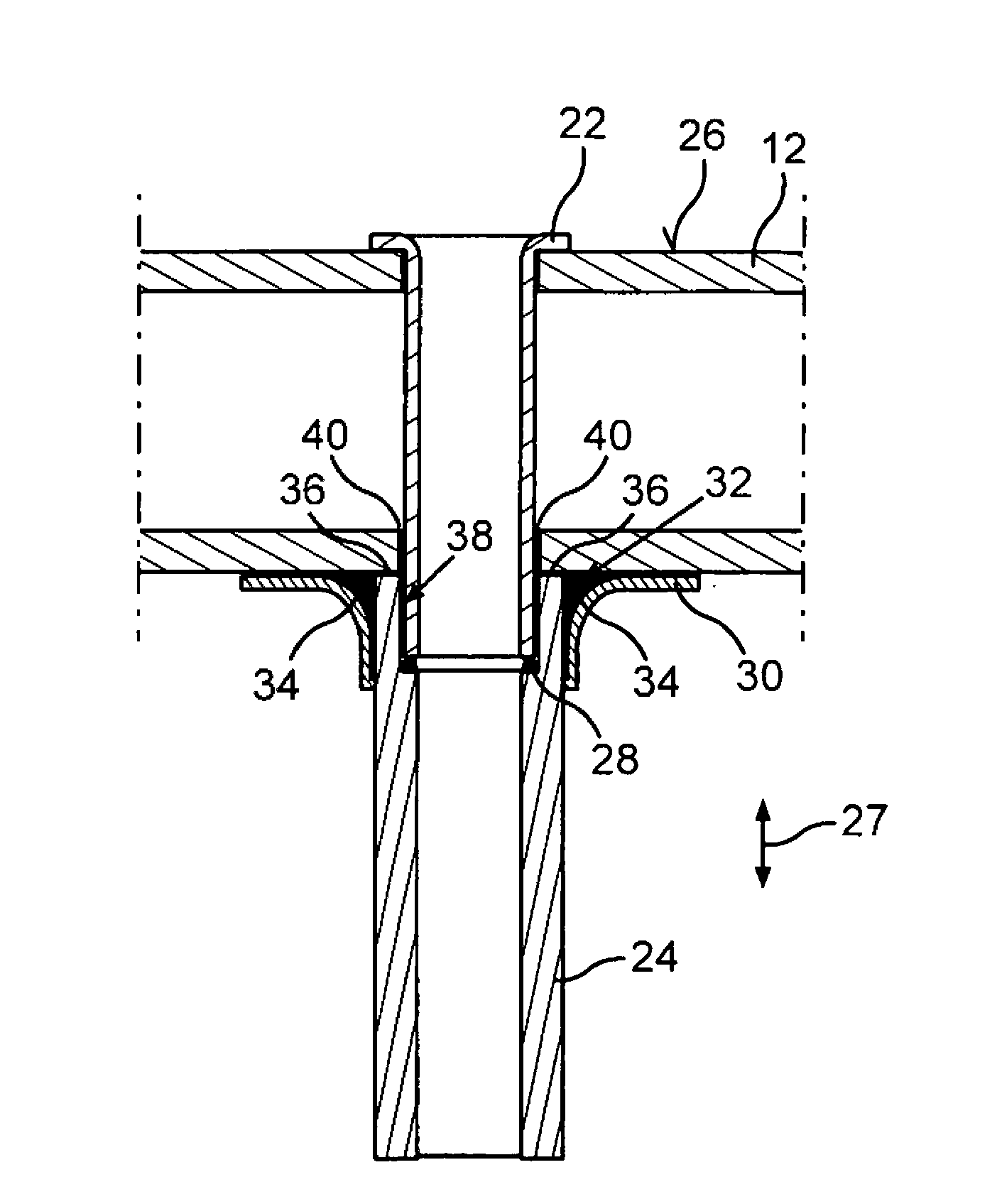

[0035] such as an overview figure 2 and image 3As can be seen, high-pressure fuel accumulator 10 includes sleeves 22 and 24 for connecting high-pressure fuel accumulator 10 to a cylinder head of an Otto or Diesel engine. The sleeve 22 passes completely through the fuel rail 12 , ie is inserted through a corresponding through-opening in the outer surface 26 of the fuel rail 12 and passes through sai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com