Clamping type shellfish cooking machine

A clamping and cooking machine technology, applied in bivalves processing, etc., can solve the problems of discontinuous cooking of shellfish, easy wear and tear of shellfish products, low production efficiency, etc., and achieve low manufacturing cost, high production efficiency, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

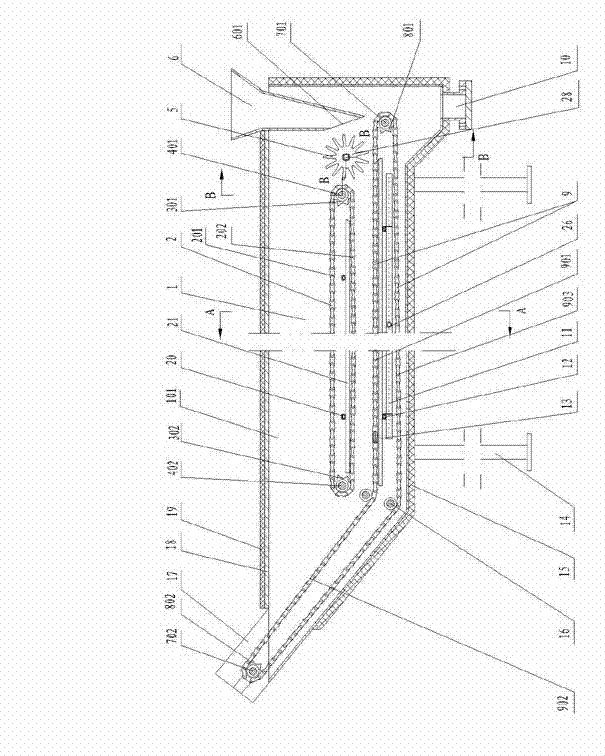

[0021] exist figure 1 Among them, a clip-on shellfish cooking machine includes a cooking tank 1 . The cooking tank 1 is supported horizontally by the frame 14.

[0022] like figure 1 As shown, the cooking tank 1 has an open notch 101 .

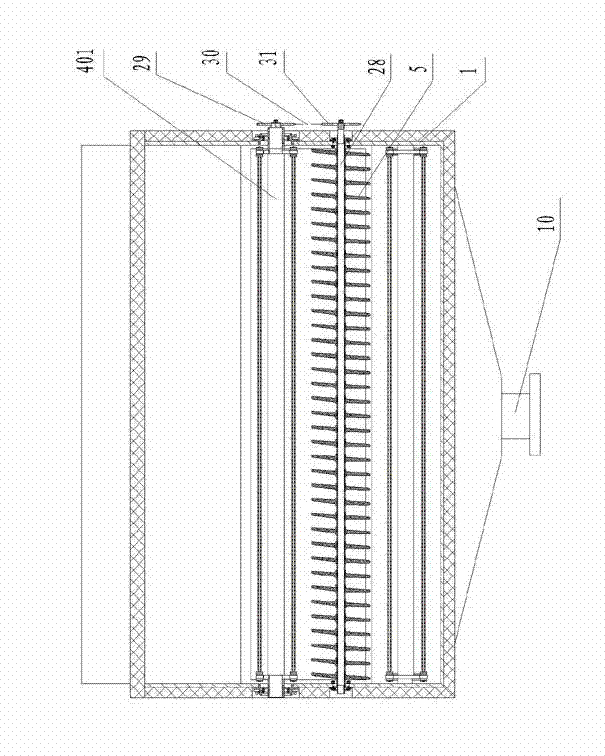

[0023] exist figure 1 , image 3 Among them, a blowdown valve 10 is provided at the tank bottom of the cooking tank 1 . For reliable sewage discharge, the tank body where the sewage valve 10 is installed is designed as a sinking structure.

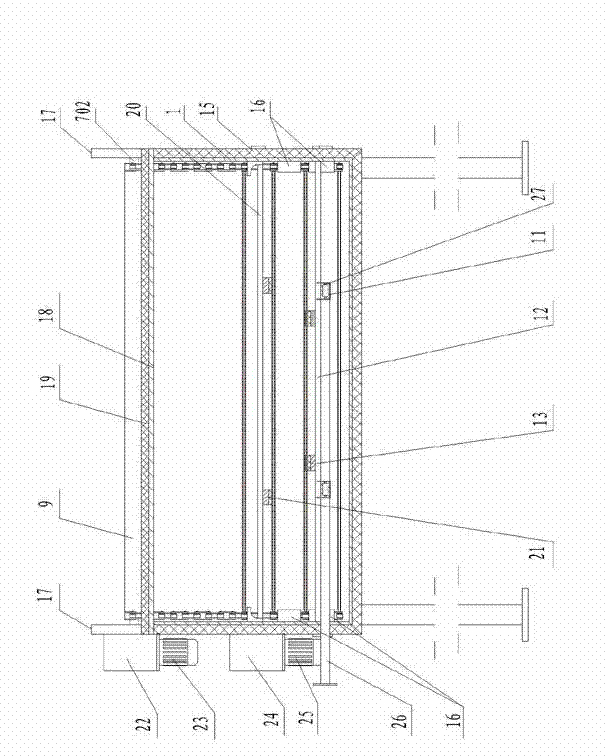

[0024] exist figure 1 , figure 2 Among them, on the output end of the cooking tank 1, a support 17 protruding from the outside of the tank body is symmetrically fixed.

[0025] like figure 1 As shown, a conveyor sprocket shaft 701 is rotatably supported inside the tank body at the input end of the cooking tank, and another conveyor sprocket shaft 702 is rotatably supported on the support 17; Two conveyor sprockets 802 are assembled symmetrically and non-rotatingly on the sprocket shaft 702, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com