A method for killing tobacco pests with low oxygen

A pest and tobacco technology, applied in the field of low oxygen killing tobacco pests, can solve the problems of reducing the alcoholization speed of tobacco leaves, decreasing the availability of tobacco leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

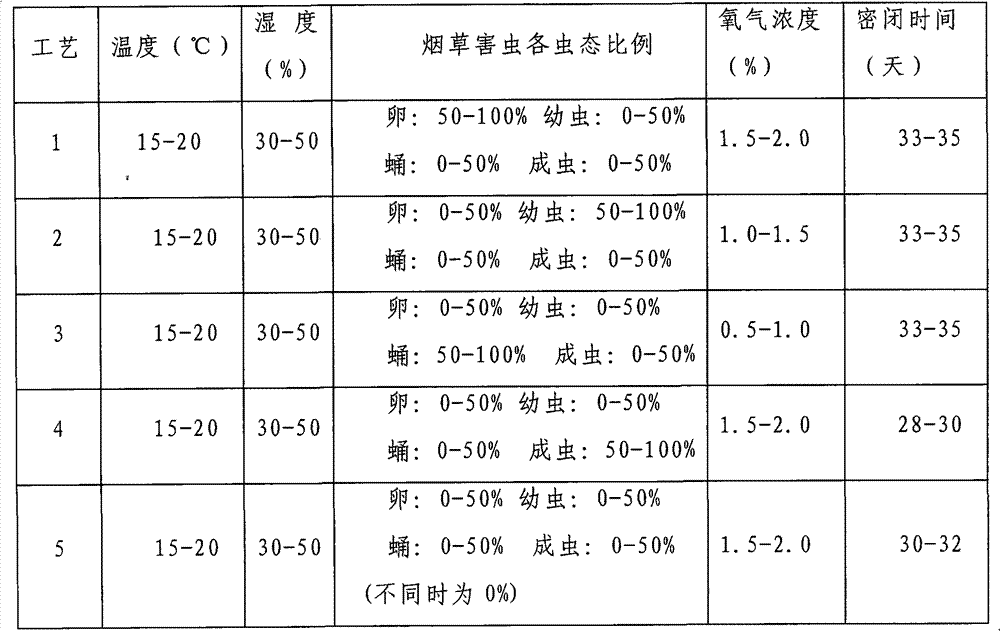

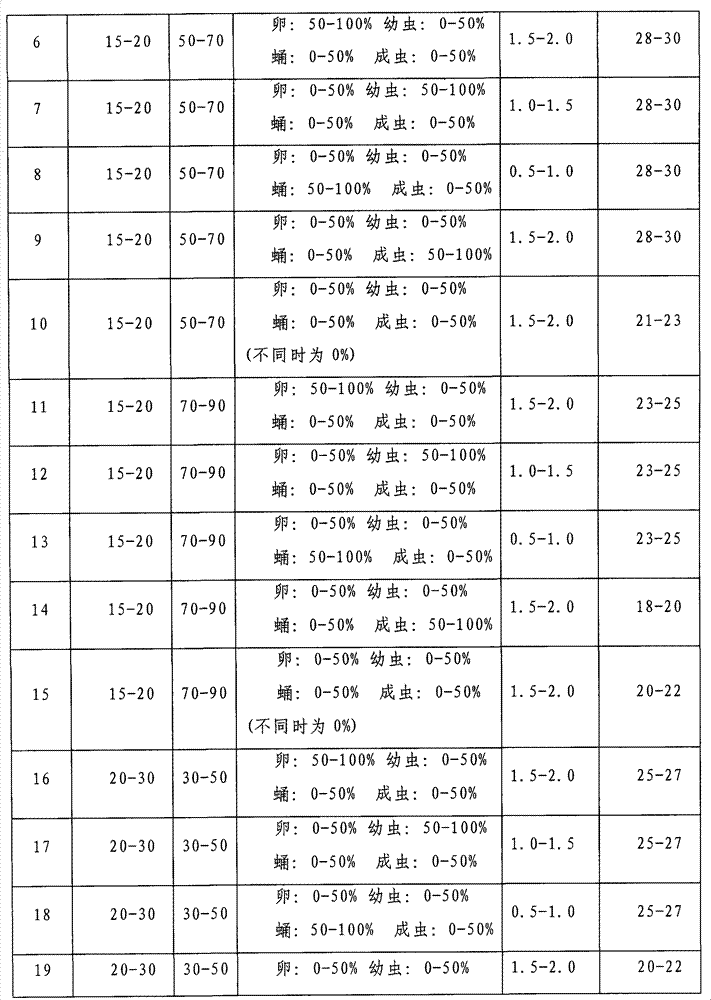

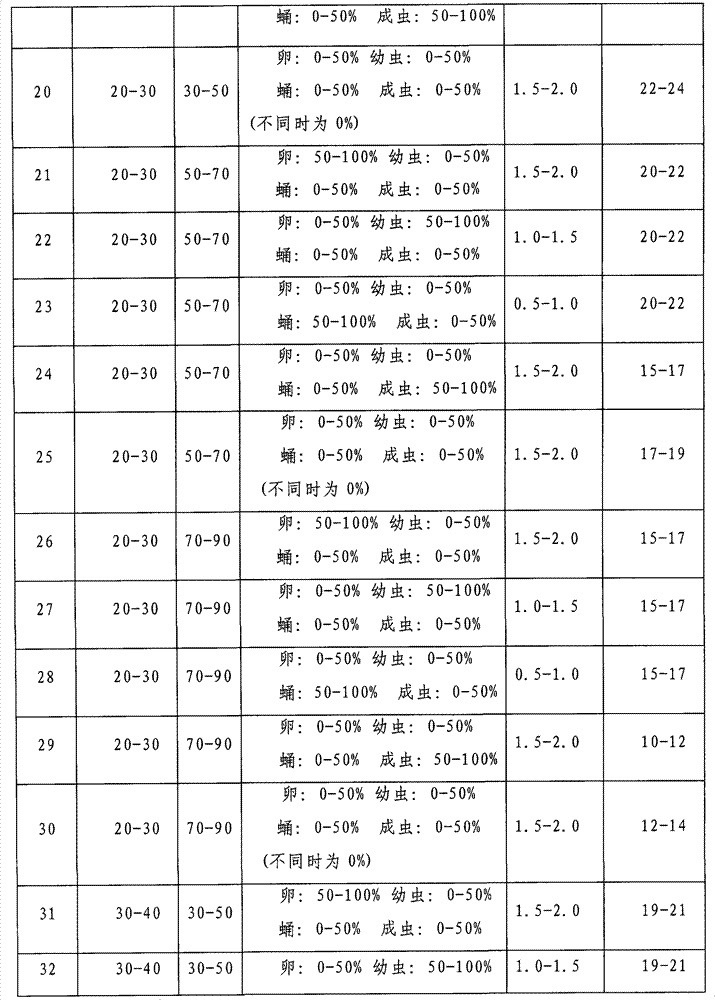

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, smoke boxes are randomly selected, and opened, turn up 5-10cm thick tobacco leaves in the box, swing slightly in the box as carefully as possible, then take a 300-500g sample as a whole, shake the sample tobacco leaves, and The pests were shaken onto the white paper, and the number of tobacco pests in each stage was counted. Among them, there were 207 tobacco pest eggs, 129 larvae, 84 pupae, and 21 adults. 19.1%, adult 4.7%.

[0044] The storage material tobacco leaves are sealed, and the steps include:

[0045] a) Determine the stacking position of the tobacco leaves, and place the bottom film of the plastic film on the stacking position;

[0046] b) stacking the tobacco leaves on the plastic film bottom film;

[0047] c) cover the cover film of plastic film, to wrap the tobacco leaf of whole stack in the plastic film;

[0048] d) Install the victor temperature and humidity detector at any relative position in the plastic film;

[0049] e) Insta...

Embodiment 2

[0057] In this embodiment, smoke boxes are randomly selected, and opened, turn up 5-10cm thick tobacco leaves in the box, swing slightly in the box as carefully as possible, then take a 300-500g sample as a whole, shake the sample tobacco leaves, and The pests were shaken onto white paper, and the number of tobacco pests in each stage was counted, including 51.1% of tobacco pest eggs, 12.8% of larvae, 24.6% of pupae, and 11.5% of adults.

[0058] The storage material tobacco leaves are sealed, and the steps include:

[0059] a) Determine the stacking position of the tobacco leaves, and place the bottom film of the plastic film on the stacking position;

[0060] b) stacking the tobacco leaves on the plastic film bottom film;

[0061] c) cover the cover film of plastic film, to wrap the tobacco leaf of whole stack in the plastic film;

[0062] d) Install the victor temperature and humidity detector at any relative position in the plastic film;

[0063] e) Install an air intak...

Embodiment 3

[0071] In this embodiment, smoke boxes are randomly selected, and opened, turn up 5-10cm thick tobacco leaves in the box, swing slightly in the box as carefully as possible, then take a 300-500g sample as a whole, shake the sample tobacco leaves, and The pests were shaken onto white paper, and the number of tobacco pests in each stage was counted, including 16.3% of tobacco pest eggs, 8.4% of larvae, 22.9% of pupae, and 52.4% of adults.

[0072] The storage material tobacco leaves are sealed, and the steps include:

[0073] a) Determine the stacking position of the tobacco leaves, and place the bottom film of the plastic film on the stacking position;

[0074] b) stacking the tobacco leaves on the plastic film bottom film;

[0075] c) cover the cover film of plastic film, to wrap the tobacco leaf of whole stack in the plastic film;

[0076] d) Install the victor temperature and humidity detector at any relative position in the plastic film;

[0077] e) Install an air intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com