A method for quickly reducing oxygen and killing insects in tobacco leaves

A tobacco leaf and fast technology, applied in the field of stored tobacco insecticide, can solve the problems of high concentration and high insecticidal cost, and achieve the effects of short oxygen reduction time, reduction of cycle time, and rapid and thorough insecticidal treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

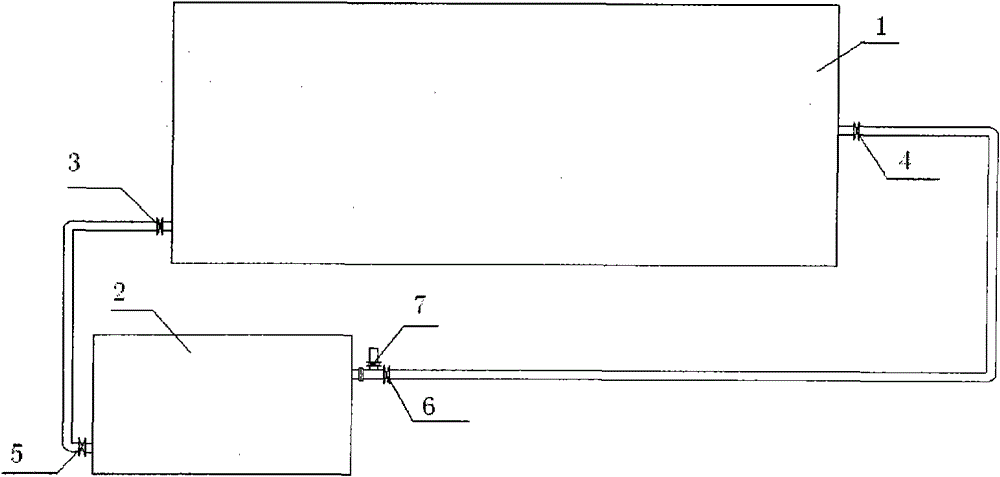

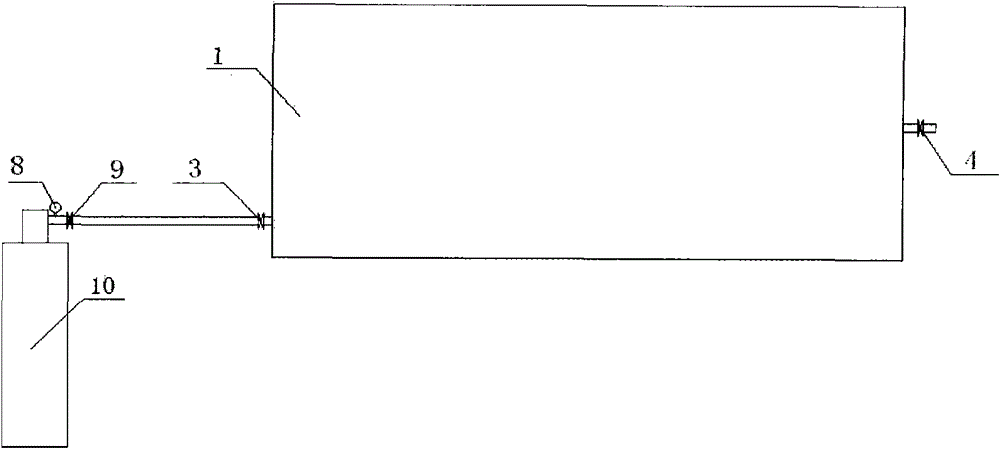

[0035] In this example, 50 rebaked tobacco sheets that have been partially infested with worms are used, and the volume of the smoke is about 30m 3 , the sealed space is a sealed tent. Such as figure 1 Shown is a schematic diagram of the connection between the sealed space and the pressure swing adsorption nitrogen production equipment in this embodiment.

[0036] This embodiment includes the following steps:

[0037] 1) Seal the stack of tobacco leaves with a sealed tent 1

[0038] Calculate the area of the bottom film of the sealed tent according to the size of the stack of tobacco leaves, and lay moisture-proof materials such as kraft paper, honeycomb cardboard, and sacks at the bottom of the stack to prevent moisture and protect the bottom film of the sealed tent.

[0039] Then lay the airtight tent bottom film made of composite film on the moisture-proof material. In this embodiment, the plastic film of the airtight tent adopts a polyethylene composite film with a t...

Embodiment 2

[0050] In this example, 100 pieces of re-cured tobacco sheets that have been partially infested with insects are used, and the volume of the tobacco leaves is about 60m 3 , the sealed space is a sealed tent.

[0051] The steps included in this embodiment are basically the same as in Embodiment 1, the difference is that:

[0052] The sealed tent plastic film adopted in step 1) is a 0.10mm thick polypropylene composite film, and the oxygen transmission rate is less than 80mL / day·m 2 .

[0053] In step 2), when the oxygen detector detects that the oxygen concentration in the airtight tent is 2%, the pressure swing adsorption nitrogen production equipment is closed, and the pressure swing adsorption nitrogen production equipment has been running for 14 hours.

[0054] In step 3), when the carbon dioxide detector measures that the carbon dioxide concentration in the airtight tent is 25%, stop inflating.

[0055] After maintaining the gas concentration described in this example f...

Embodiment 3

[0057] In this example, 150 pieces of rebaked tobacco that have been partially infested with insects are used, and the volume of the tobacco is about 90m 3 , the sealed space is a sealed tent.

[0058] The steps included in this embodiment are basically the same as in Embodiment 1, the difference is that:

[0059] The sealed tent plastic film used in step 1) is a 0.12mm polyester composite film, and the oxygen permeability is less than 100mL / day·m 2 .

[0060] In step 2), when the oxygen detector detects that the oxygen concentration in the airtight tent is 0.5%, the PSA nitrogen-generating equipment is turned off, and the PSA nitrogen-generating equipment has been running for 48 hours.

[0061] In step 3), when the carbon dioxide detector measures that the carbon dioxide concentration in the airtight tent is 50%, stop inflating.

[0062] After maintaining the gas concentration described in this example for 2 days, the airtight tent was removed, and the mortality rate of to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com