Core insert mechanism used for cold roll forming of car doorframe

A cold-formed and door frame technology, applied in the field of automobile door frame processing equipment, can solve the problems of large gap, low work efficiency, unsatisfactory effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

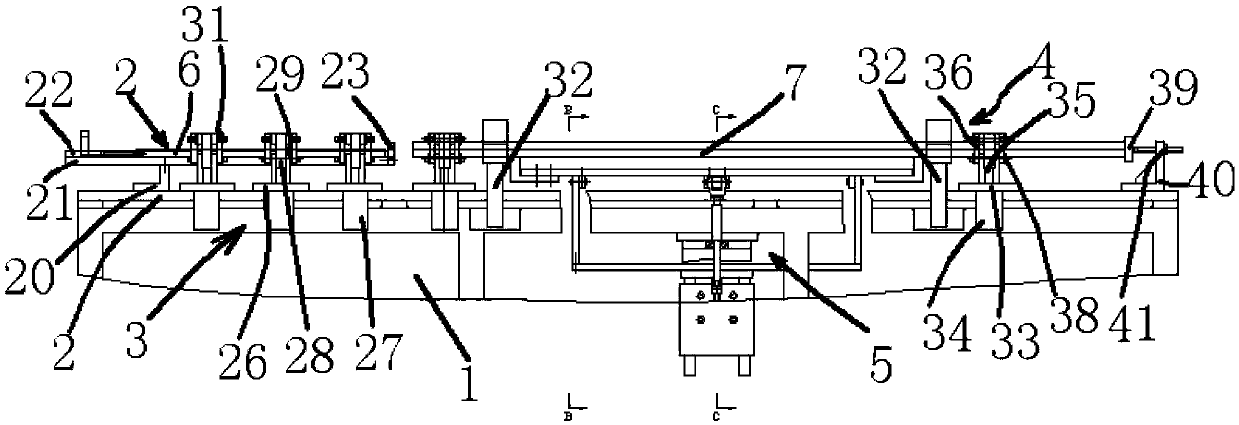

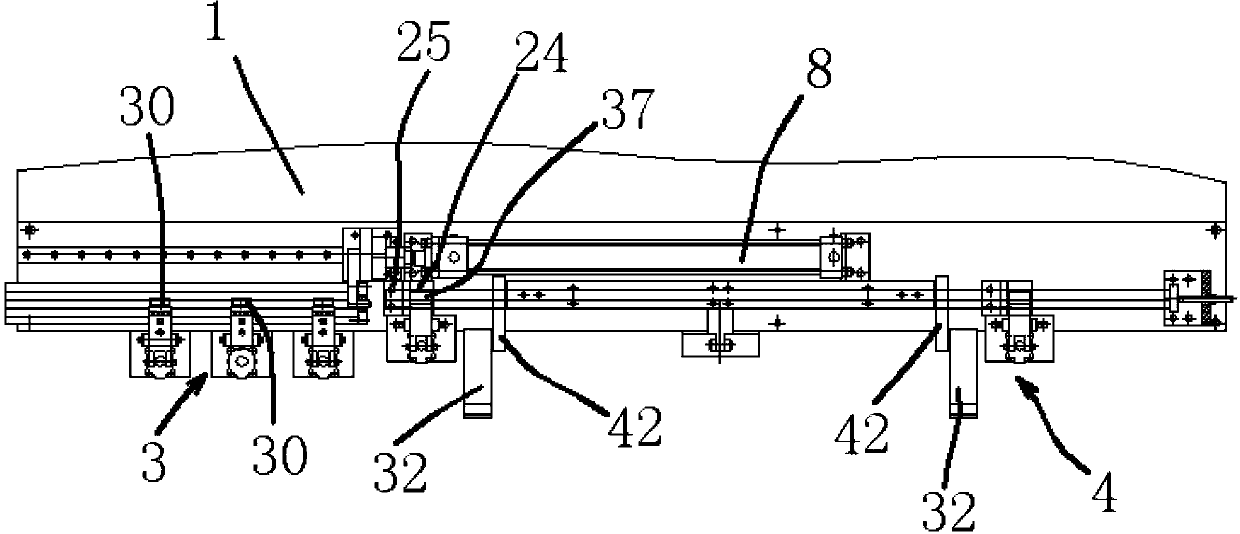

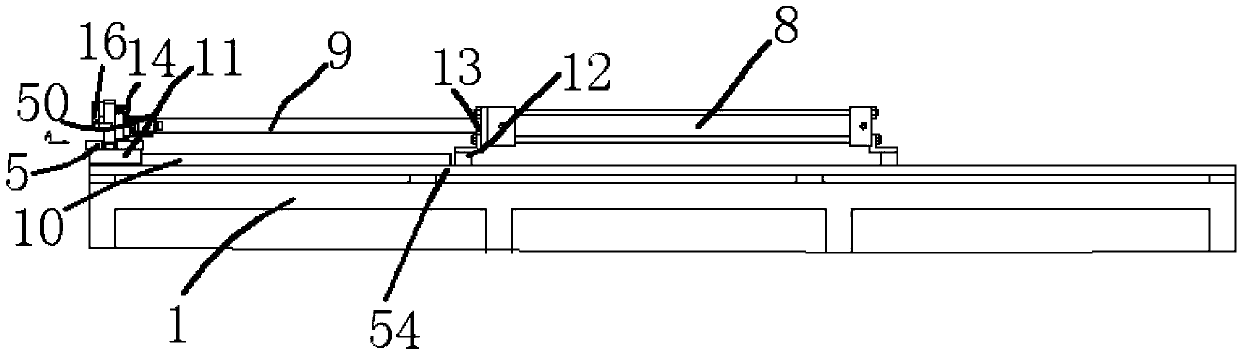

[0026] Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, the inserting core mechanism used for the cold-bending forming of automobile door frames is mainly to automatically introduce the mandrel 6 into the inner cavity of the door frame 7 to facilitate cold-bending forming. The rod 6 is introduced into and exported from the material guide mechanism 2 in the inner cavity of the door frame 7, the mandrel pressing mechanism 3 for pressing and fixing the mandrel 6 on the material guide mechanism 2, and the door frame pressing mechanism for pressing and fixing the door frame 7. The fastening mechanism 4 and the unloading mechanism 5 for automatically unloading the processed door frame 7.

[0027] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com