Continuous cutting process suitable for small workpieces

A technology for cutting technology and small workpieces, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of large loss, many empty paths in the moving path, waste of fuel, etc., achieve high cutting quality, reduce energy consumption, reduce The effect of empty space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

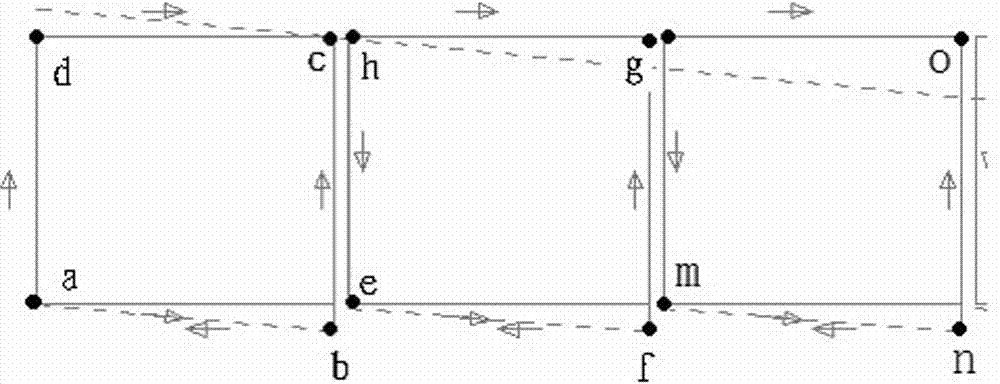

[0015] Embodiment 1, as image 3 , 4 As shown, a continuous cutting process suitable for small workpieces, the steps are to start punching from the starting point A of the first cutting unit, then cut the left side vertically downward along the straight line AC at this point, and then cut horizontally along the straight line CD The bottom edge, and then cut the right side upward along the straight line DE direction to complete the continuous cutting of the three sides of a rectangle, and then cut horizontally from the highest point E to the starting point F of another rectangular unit, and continue to the next round of three sides ( F-G-H-I-J) cutting, according to the length of the iron plate, there are a total of 10 workpieces. After cutting the three sides of the ten workpieces, finally cut the upper edge horizontally and return to the end point B of the first cutting unit to complete the entire top edge cutting, horizontal The height of the long-distance cutting edge (tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com