Permanent magnet guide device for semi-automatic welding trolley

A semi-automatic welding and guiding device technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of cumbersome operation and poor positioning accuracy, and achieve the effect of simple operation, simple structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

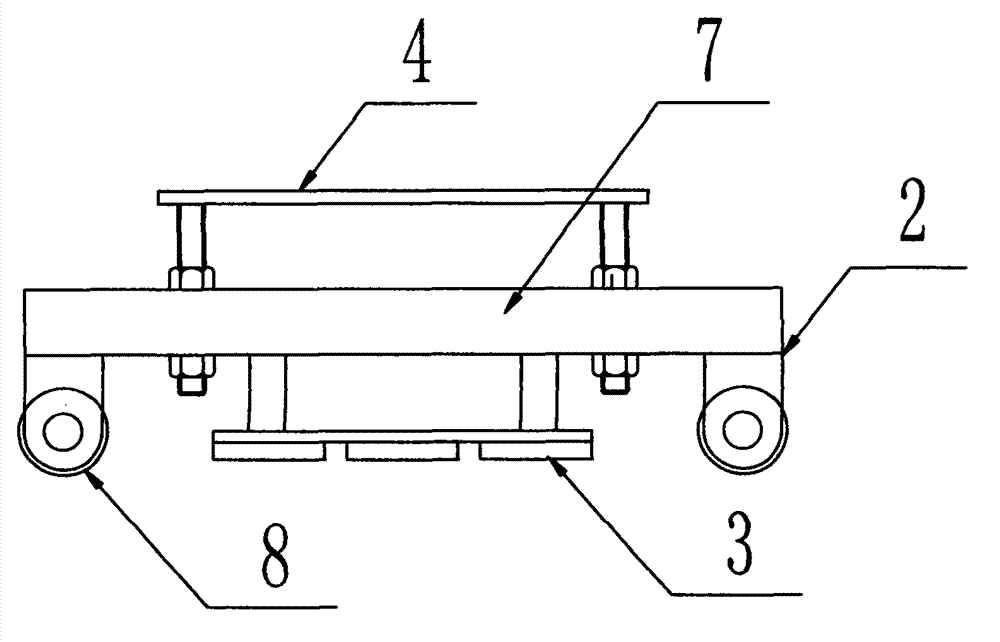

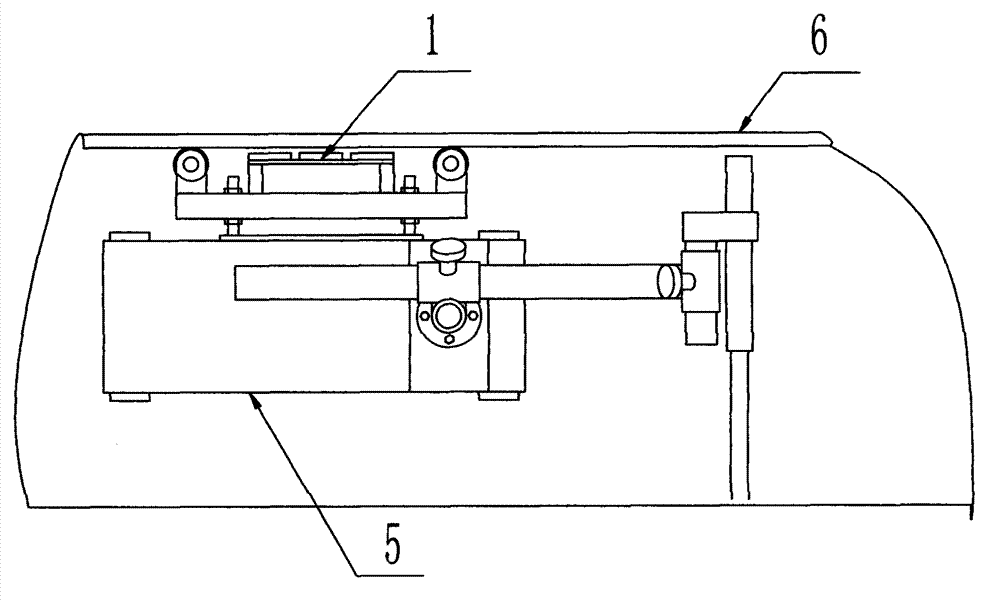

[0012] A permanent magnet guiding device for a semi-automatic welding trolley, the guiding device 1 includes a bracket 2, a permanent magnet 3 is installed on one side of the bracket 2, and a fixed connecting plate 4 is connected to the other side, and one side of the bracket 2 passes through the fixed connecting plate 4 Fixed on the semi-automatic welding trolley 5, the other side is adsorbed on the plate girder rib 6 by the permanent magnet 3, and is in contact with the plate girder rib 6, and the permanent magnet 3 is not in contact with the plate girder rib 6.

[0013] Above-mentioned support 2 is the " U " shape structure that is made up of square tube 7 and the bearing 8 that is connected at two ends of square tube 7 , permanent magnet 3 is installed in the middle part of square tube 7 , and bearing 8 is adsorbed on by the magnetic force of permanent magnet 3 On the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com