Material returning device for full-automatic numerical control grinder

A CNC grinding machine, fully automatic technology, applied in milling machine equipment, parts of boring machine/drilling machine, drilling/drilling equipment, etc., can solve the problems of disorder, danger, falling into the collecting box, etc. Easy to collect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

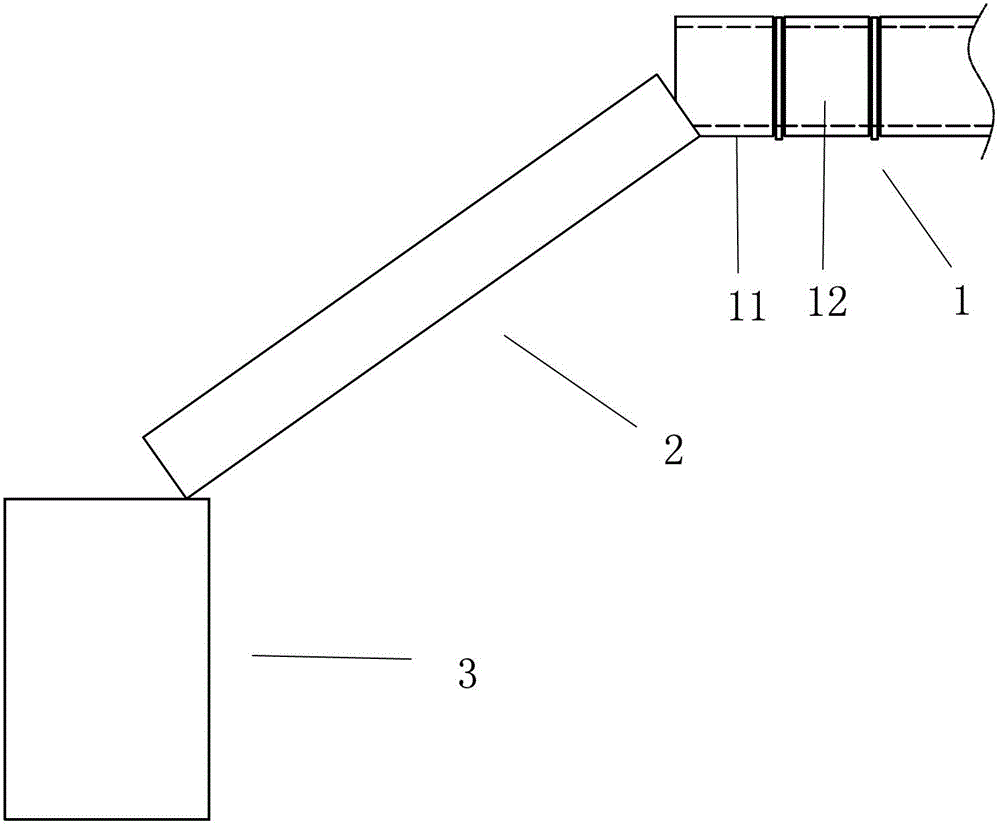

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4:

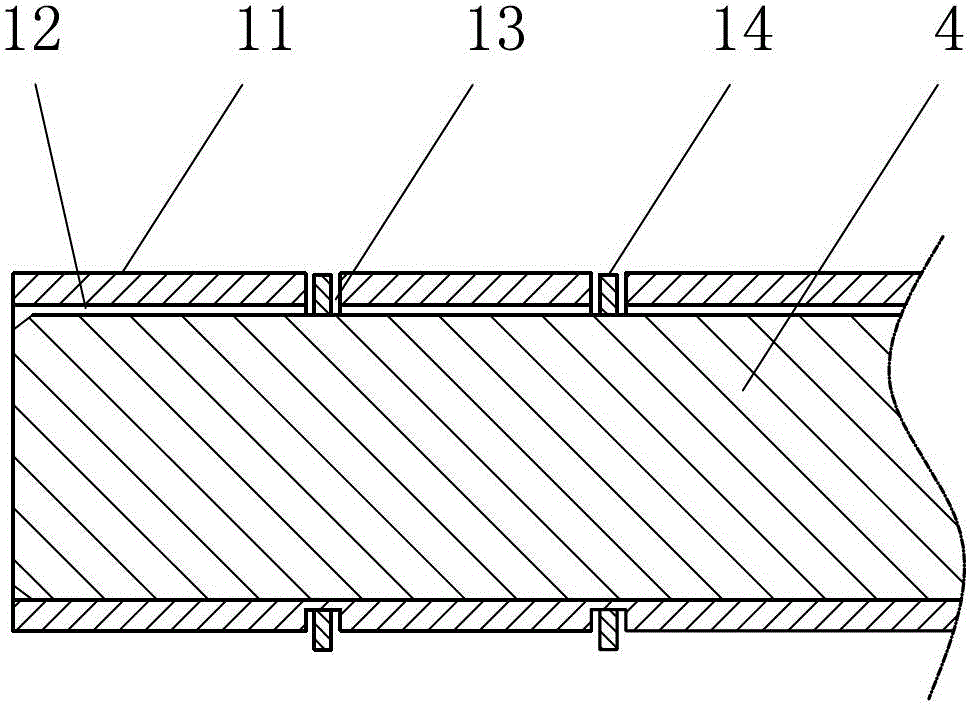

[0019] The fully automatic CNC grinding machine unloading device includes a hollow workpiece fixture spindle 11 and a bed base. The tail of the workpiece fixture spindle 11 is provided with an elastic workpiece clamping device 1. The bed base is provided with an automatic straightening device from the tail of the workpiece fixture spindle 11 to the bed base. The collection box 3 of workpiece is provided with the slideway 2 obliquely.

[0020] The specific structure of the above-mentioned elastic workpiece clamping device 1 is: the tail of the workpiece fixture spindle 11 is provided with more than one (the present invention has two) arc-shaped holes 13 connected with the inner hole 12, and the arc-shaped holes 13 are clamped with C-shaped elastic ring 14.

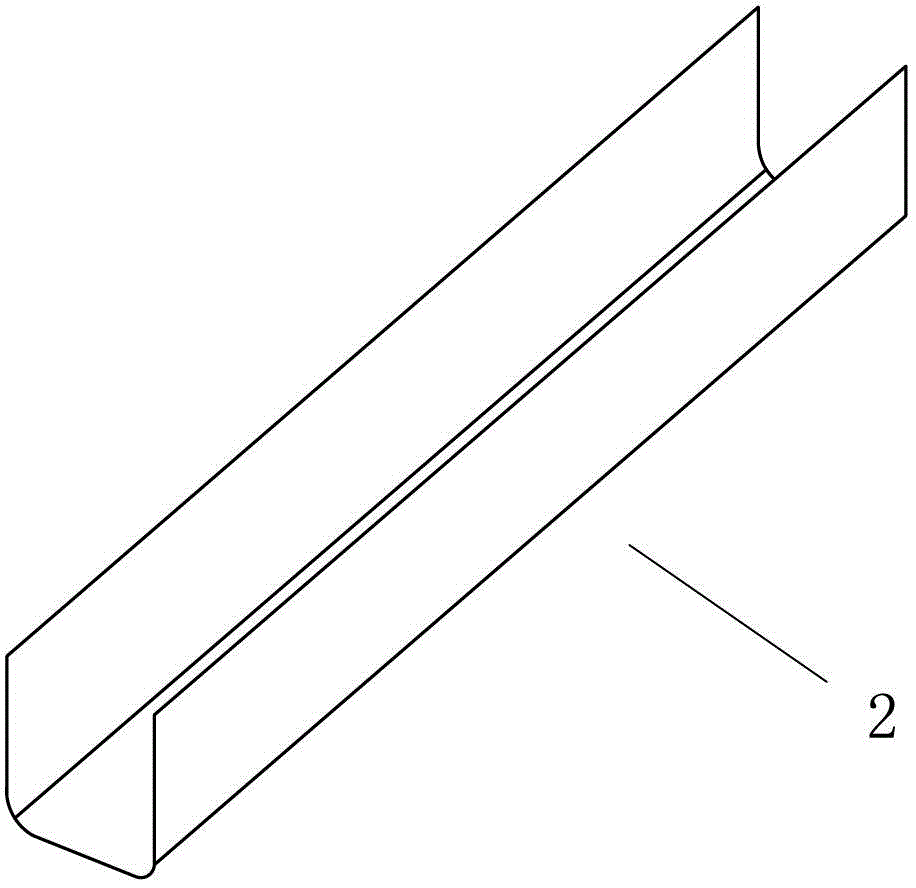

[0021] Above-mentioned slideway 2 is U-shaped body or C-shaped body or O-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com